Solid Tungsten Carbide End Mill System Ⅴ

- Details

- Category: Tungsten Information

- Published on Monday, 02 November 2015 17:39

In part 4 we know that solid tungsten carbide end mill selection depends most importantly on machining strategy concerning feeds, speeds, depths of cut, which includes two directions: performance driven selection or application driven selections. Here we talk about the basic solid tungsten carbide milling cutter types.

Milling Cutter Type Choices

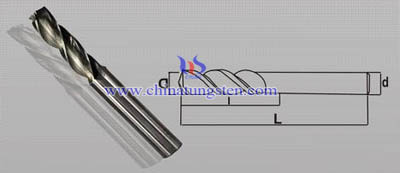

With approximately five distinct solid tungsten carbide end mill types in existence today for common applications in metallic materials, one generic tool type stands out as being somewhat outdated. It’s a solid tungsten carbide cutter that dates back to the days when small end mills were made of high speed steel (HSS). Historically referred to as the first generation of solid carbide end mills, it has the typical geometrical features that were used in HSS tools at the end of the 1970’s except that its base material has been switched to solid carbide which was found to be suitable for the task at that time. These types of cutters today define the lower end of the market both in terms of cost and performance.

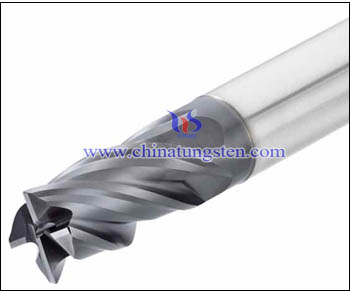

The second group of cutters which in contrast is highly contemporary is the high speed milling type (HSM) of cutters defined for high cutting speeds. These tools typically feature a rather short usable cutting edge length and their design is optimized for maximum stability. With the application of high cutting speeds, high temperatures are generated and this heat typically accumulates in the tool corner. This is the reason why HSM end mills most often have larger corner radii for extra protection against plastic deformation in this area.

The third group for high performance milling (HPM) that holds tools specifically designed for high depths of cut and larger arc of engagement. The depth of cut being the optimizing factor here, the tool design reflects this with long cutting edge length and chip dividers to make large chip volumes more manageable. Helix angles and chip cavity capacity are other visible elements of importance. Increased cutter core diameters are also found with these tools. Their aim is to increase tool stability and again reduce deflection.

(To be continued. This article is divided into several parts and this is part 5, for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/79882-ti-10226; for part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/79931-ti-10236)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Solid Tungsten Carbide End Mill System Ⅳ

- Details

- Category: Tungsten Information

- Published on Friday, 30 October 2015 13:51

In part 3 we know that solid tungsten carbide end mills have relatively sharp edges and an edge preparation is necessary for the coatings to adhere firmly to the substrate and avoid edge breakage, thus increase the stability, functionality and life span of cutting tools .Here we talk about machining strategy.

(To be continued. This article is divided into several parts and this is part 4, for part 3 please refer to http://news.chinatungsten.com/en/tungsten-information/79881-ti-10225)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Solid Tungsten Carbide End Mill System Ⅲ

- Details

- Category: Tungsten Information

- Published on Friday, 30 October 2015 13:48

In part 2 we know that solid tungsten carbide end mills have different temperature handling characteristics versus insert milling cutters, and so for diameter below 10mm, carbide end mills are suggested, but for large diameter, insert milling cutters are suggested. Here we talk about coatings and edge preparations.

Coatings And Edge Preparations

Coatings are applied to solid tungsten carbide end mills to increase wear resistance and isolate the area where the heat is generated from the substrate of the tool, in which it could potentially accumulate and affect the tool life span negatively. Additionally, solid tungsten carbide end mills have relatively sharp cutting edges, it is thus very important to have correct coating adhesion between the substrate material and the coating layers. In particular, with smaller diameter solid cutters, cutting edge sharpness is a crucial element contributing to tool performance. An ideal cutting edge would consist of a sharp cutting edge with the highest possible hardness without the risk for breakage. This can be in part achieved with an appropriate edge preparation. Most often, the style, shape and sharpness of the (cutting) edge preparation sets different solid carbide milling cutters apart both in terms of generated work quality and tool life levels reached.

A relatively sharp cutting edge is achieved through grinding both the top rake face as well as the clearance face on the tool. The line where the two faces meet each other is referred to as the cutting edge. Cutting edges will need reinforcements or a so called edge treatment/honing in order for the coating to better adhere to it and prevent edge breakouts. In other words, some of the edge sharpness is traded for stability and coating functionality, which in turn leads to longer tool life. It can even be discussed that the edge preparation has the highest importance of all followed by both substrate type and coating technology.

(To be continued. This article is divided into several parts and this is part 3, for part 2 please refer to http://news.chinatungsten.com/en/tungsten-information/79854-ti-10211; for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/79882-ti-10226)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Solid Tungsten Carbide End Mill System Ⅱ

- Details

- Category: Tungsten Information

- Published on Thursday, 29 October 2015 19:04

In last part we know that a solid tungsten carbide end mill is in many ways different from an insert milling cutter, such as, they have different types of coatings and substrates, same tolerances but different material stiffness and thus precision levels, and arc of tool contact. Here we go on exploring the characters of solid tungsten carbide end mill system.

Solid tungsten carbide end mills and steel based insert milling cutters have completely different characteristics in temperature handling and this should be reflected in the cutting strategy selection. Considering these facts and putting things further in perspective one has to look at tool dimensions too.

In the smaller diameter range below 10 mm there are very few insert based alternatives to solid tungsten carbide cutters and the choice is clearly going toward solid end mills. The opposite applies for tools with large diameters where solid carbide tools are not a viable choice for economical reasons. This leaves us with the intermediate range of sizes between 10 to approximately 25 mm where many system overlaps exist. The complexity of the shape to be machined, its accessibility and tolerances to be held are the guiding stars for initial tool selection here.

(To be continued. This article is divided into several parts and this is part 2, for part 1 please refer to http://news.chinatungsten.com/en/tungsten-information/79853-ti-10210)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Solid Tungsten Carbide End Mill SystemⅠ

- Details

- Category: Tungsten Information

- Published on Thursday, 29 October 2015 19:01

A basic question often asked when one has both an insert based cutter and a solid carbide cutter is which one is the best and in what areas do they excel? This is not so much a question of one being superior over the other but rather a question regarding the features of a specific type of cutter and how that particular tool should be applied to deliver good results.

An insert milling cutter is different from a solid tungsten carbide milling cutter in many ways. Different types of coatings and different types of substrates are used with solid carbide cutters as compared to insert based systems and that makes for a number of significant feature differences between these two main groups. If some of the features in one of these two groups becomes more important in a certain application, then that tool is perhaps more suitable for the application.

Tolerances on both tools can be equally narrow, statically, but since solid carbide as a material is much stiffer compared to a steel shank tool with a mounted insert, it is prone to less bending and thus has a higher level of precision under the influence of cutting forces during machining.

Another important fact to remember is the arc of tool contact. The arc of tool contact or in other words the length of the circumference of a particular tool that is in contact with a machined part is directly linked to the amount of heat that is generated and absorbed into the tool, component or chips.

(To be continued. This article is divided into several parts and this is part 1, for part 2 please refer to ; for part 16 please refer to )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Infiltration V

- Details

- Category: Tungsten Information

- Published on Thursday, 29 October 2015 17:50

At the present, tungsten skeleton shaping includes compression molding, extrusion molding and injection molding, etc. For compression molding, the suppress pressure, velocity and holding time will directly affects the products. And the suppress is related to tungsten copper contents, tungsten content, Cu-induced content and the proportions of tungsten powder granularity, aspect ratio or shaping agent and mold discharging agent. On the premise of density of suppress blank, prolong the suppress time properly will reduce the elasticity of the stamper after divorcing.

There are few literatures about extrusion molding, some researchers use paraffin as plasticizer and study the choice of material, the amount and the process of wax-doped, pre-pressing, the temperature of extrusion molding, dewaxing and presintering, which plays an important role in extrusion molding of tungsten skeleton. And they thought when tungsten content of tungsten skeleton is 70% - 90%, the infiltration and other properties will be stable.

More infomation about tungsten copper electrode infiltration, click here:

http://news.chinatungsten.com/en/tungsten-information/79730-ti-10171

http://news.chinatungsten.com/en/tungsten-information/79780-ti-10172

http://news.chinatungsten.com/en/tungsten-information/79781-ti-10175

http://news.chinatungsten.com/en/tungsten-information/79849-ti-10176

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Infiltration IV

- Details

- Category: Tungsten Information

- Published on Thursday, 29 October 2015 17:45

Besides, mixed with light of Cu-induced powder will improve the corrosion ratio and the efficiency. Chinese scholars use 0.8-3.0μm tungsten powder for mixing, the result shows that despite small average granularity of tungsten powder, the density of sintering blank is still lower and the micro-structure is maldistributed.

Viewed from tungsten skeleton, it is a key of high density tungsten copper electrode manufacturing by infiltration. Due to tungsten (W) has high melting point, high hardness and low contraction, it is difficult to be machining and densifying, which becomes the major part of scholars study. The study of tungsten skeleton can be divided into two types, one is the shaping properties of tungsten skeleton, and the other is the sintering properties of tungsten skeleton.

More infomation about tungsten copper electrode infiltration, click here:

http://news.chinatungsten.com/en/tungsten-information/79730-ti-10171

http://news.chinatungsten.com/en/tungsten-information/79780-ti-10172

http://news.chinatungsten.com/en/tungsten-information/79781-ti-10175

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer ⅩⅥ

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 October 2015 18:20

In part 15 we know that for tungsten carbide reamer, aluminum and brass have relatively better machinability than cast iron, plastics and stainless steel, and during reaming process proper lubrication helps cool tool, increase cutting speeds, remove chips and thus increases effect. And here we list the specific application ways of different cutting fluid for various work materials on which we use a tungsten carbide reamer to machine.

|

Work Material |

Cutting Fluid |

Application |

|

Aluminum |

Soluble oil, kerosene, synthetic fluid |

Flood |

|

Brass |

None, soluble oil |

Flood |

|

Cast Iron |

Cold air, none |

Air jet |

|

Mild steel |

Soluble oil, sulfurized oil |

Flood |

|

Stainless steel |

Soluble oil, sulfurized oil |

Flood |

|

Plastics |

None, mineral oil, synthetic oil |

Flood, spray |

(To be continued. This article is divided into several parts and this is part 16, for part 15 please refer to http://news.chinatungsten.com/en/tungsten-information/79784-ti-10204)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer ⅩⅤ

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 October 2015 18:15

In part 14 we know that versus high-speed steel reamers, tungsten carbide reamers are more expensive, but are can be applied to ream hardened materials with a longer life because of its much greater hardness. And here we explain shortly the work piece materials and lubrication during reaming process.

(To be continued. This article is divided into several parts and this is part 15, for part 14 please refer to http://news.chinatungsten.com/en/tungsten-information/79734-ti-10199; for part 16 please refer to http://news.chinatungsten.com/en/tungsten-information/79785-ti-10205)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Infiltration III

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 October 2015 16:43

Other experiment uses three different granularity of tungsten powder (8.7μm, 23.2μm and 65.2μm) for W-15Cu tungsten copper electrode. They thought different process parameters and tungsten powder granularity accounts for obturator or the changing of W-W adjacency rate, which has an effect on the density and resistivity. Nowadays, tungsten copper contacts made of 4-8μm (tungsten powder) granularity is widely used worldwide, which has good molding, contraction, low coefficient of thermal expansion and it is easily to be controlled in size or the porosity of tungsten blank.

In order to achieve that corrosion ratio and the efficiency of machining in electrical discharge machining (EDM) with tungsten copper electrode by diverse granularity of tungsten powder, researchers use 1.0-3.0μm five kinds of tungsten powder as tungsten copper electrode. It demonstrates that 2.0 μm average granularity of tungsten copper has better properties in 80WC-20Co tungsten carbide machining.

More infomation about tungsten copper electrode infiltration, click here:

http://news.chinatungsten.com/en/tungsten-information/79730-ti-10171

http://news.chinatungsten.com/en/tungsten-information/79780-ti-10172

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com