Procedure to Make Tungsten Carbide Cutting Tools Ⅵ

- Details

- Category: Tungsten Information

- Published on Thursday, 12 November 2015 16:24

In last part we know that grade powder is compacted by ways such as uniaxial pressting or isostatic pressing to form a blank shape of tungsten carbide cutting tool and then it goes for sintering. Here we go forward to the process of sintering.

Sintering

In order to increase the strength of the green compacts, they are subjected to heat treatment, which is called sintering. The main aim of sintering is densification in order to provide the metal with the necessary physical and mechanical properties and a density which is suitable for subsequent thermomechanical processing. Sintering of tungsten carbide is commonly carried out in a temperature range of 1500 up to 1500℃ under flowing hydrogen, either by direct sintering (self resistance sintering) or indirect sintering (resistance element heating systems). The density thereby obtained should be a minimum of 90% of the theoretical density, but is commonly in the range of 92% to 98%.

Let’s take tungsten carbide inserts for instance. After pressing, the form looks like oversized inserts and is fairly delicate. They are removed from the molds and placed on graphite or molybdenum trays, and go into a sintering furnace where they are heated in a low-pressure hydrogen atmosphere. The cobalt melts, and the insert consolidates into a solid, smaller size. After the inserts are removed from the furnace and cooled, they are dense and hard. After a quality control check, the inserts are ready for further machining.

(To be continued-This article is divided into several parts and this is part 6, for part 5 please refer to http://news.chinatungsten.com/en/tungsten-information/80275-ti-10328; for part 7, please refer to http://news.chinatungsten.com/en/tungsten-information/80277-ti-10330)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Procedure to Make Tungsten Carbide Cutting Tools Ⅴ

- Details

- Category: Tungsten Information

- Published on Thursday, 12 November 2015 16:21

In last part we know how the grade powder is gained by mixing up the grade ingredients in a ball mill and drying them in a spray dryer, which also influences much the final quality of tungsten carbide cutting tools. Here we explain the procedure of compacting.

Compacting or Pressing

The grade powder is consolidated into a compact by two main routes: pressing in rigid dies (uniaxial pressing) and isostatic pressing in flexible molds (compaction under hydrostatic pressure). Other techniques, such as powder rolling, cold extrusion, explosive compaction, slip casting, vibratory compaction, or metal injection molding, have gained no industrial importance.

Tungsten powder is not easy to compact due to its relatively high hardness and difficult deformation. Nevertheless, in most cases compaction is performed without lubricant to avoid any contamination by the additive. The resulting compacts are generally sufficiently strong so that they can be handled without breaking. For machining the part, it must be pre-sintered beforehand.

Take tungsten carbide inserts as an example. The grade powder goes into insert shaped molds specially designed to allow for the shrinkage that will happen later on in the process. The powder is compressed into the molds, in a process similar to how pharmaceutical tablets are formed.

(To be continued-This article is divided into several parts and this is part 5, for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/80274-ti-10325; for part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/80276-ti-10329)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Procedure to Make Tungsten Carbide Cutting Tools Ⅳ

- Details

- Category: Tungsten Information

- Published on Thursday, 12 November 2015 16:19

In last part we know that tungsten carbide grain size is key to the properties of final tungsten carbide cutting tools, together with additives such as binder cobalt, carbides of titanium, tantalum, niobium, etc. Here we explain the process of mixing up.

Mixing Up

All these ingredients used to make tungsten carbide are blended with a liquid such as alcohol or hexane and placed in a mixing vessel, often a rotating drum called a ball mill. In addition to the grade ingredients, cemented balls 1/4″ to 5/8″ in diameter are added, to help the process of adhering the cobalt to the tungsten carbide grains. A ball mill may be as small as five inches in diameter by five inches long, or as large as a 55-gallon drum.

When the mixing is complete, the liquid must be removed. This typically happens in a spray dryer, which looks like a stainless steel silo. An inert drying gas, nitrogen or argon, is blown from the bottom up. When all the liquid is removed, the remaining dry material is “grade powder,” which looks like sand. The level of mixing up all ingredients affects the uniformity of grade powder and then finally has great effect on the final tungsten carbide cutting tools.

(To be continued-This article is divided into several parts and this is part 4, for part 3 please refer to http://news.chinatungsten.com/en/tungsten-information/80247-ti-10323; for part 5 please refer to http://news.chinatungsten.com/en/tungsten-information/80275-ti-10328)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Synthesis of the Hexagonal Form of Tungsten Trioxide from Peroxopolytungstate via Ammonium Paratungstate Decahydrate

- Details

- Category: Tungsten Information

- Published on Thursday, 12 November 2015 09:44

Two types of crystalline (NH) 4) 10[H 2W 12O 42]·10H 2O were precipitated in sequence when an ammonia solution of , peroxopolytungstate was neutralized with hydrochloric acid. It was found by X-ray diffraction that one of them is an unknown phase of ammonium paratungstate, and the other is the reported one. Heating the former, it turned directly to common triclinic WO 3. On the other hand, the latter yielded the hexagonal form of WO 3 (h-WO 3) in the temperature range 350-370 °C. This is a new synthetic method of h-WO 3, though the final precursor is a known compound. The color of h-WO 3 thus formed was pale yellow and contained a small amount of residual ammonia (N/W = 0.017 in molar ratio). Its crystallographic c-axis (7.689 Å) was shorter than than the reported value (7.798 Å) for the same WO 3 phase synthesized from 3WO 3·H 2O.

Tungsten Oxide, Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Why Tungsten is the Perfect Metal for Bullets and Missiles

- Details

- Category: Tungsten Information

- Published on Thursday, 12 November 2015 09:37

Tungsten is almost three times as dense as iron, almost twice that of lead and virtually the same as gold, its high density made itself that earned it is name which is comes from Swedish: tungsten heavy stone.

All sorts of weird applications have evolved to exploit tungsten's unique qualities. As we know, its density could rage from 17.0~18.5g/cm3, and the hardness usually from 24~28HRC, besides, when it comes to be used as the bullet, then the hardness should be controlled at least 40HRC, that is the most important reason why the military has called tungsten into service in another kind of evolutionary arms race, and also it is a prefer material called green bullet for tungsten missiles for it is non-toxic.

Tungsten makes very good bullets, which is the kind of thing that if you fire it at someone else's armour, and it will go right through it and kill it. Just like the creatures of the Cambrian period, once someone starts using teeth (or tungsten bullets and missiles) you need to do something about it. If you introduce tungsten into your bullets you've got to introduce tungsten into your armour. The fascinating balance military engineers have to negotiate between the strength of tungsten and the costs in fuel and manoeuvrability all that extra weight brings.

Now they could put the tungsten on the side of the tank but not on the top. Then people are developing warheads that will fly towards the tank and then at the last minute go up and then drop on it, so then you have to start arming the top of the tank. So tungsten metal is a perfect for bullets and missiles.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pressing Process Effect on Tungsten Copper Electrode Properties

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2015 17:26

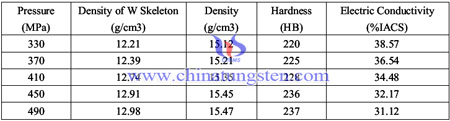

It is important that choose proper pressing process has remarkably effect on the density of tungsten skeleton and the structure of tungsten copper electrode. There are tungsten copper electrode properties under five different pressing pressures at 1300℃ as follow:

The table shows that with the increasing pressing pressure, the density and hardness of powder with same granularity is increasing, but the conductivity decreases.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Mechanism of Tungsten Copper Electrode for EDM

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2015 17:23

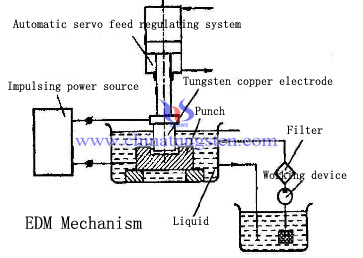

Electrical Discharge Machining (EDM), in the process of machining, produces discharging spark between the tool and the work-piece constantly, which remove the material depends on part of high temperature. EDM has many advantages, such as it can be suitable for some super-hard material cutting (tungsten carbide, cubic boron nitride, HHB), and it has high machining precision.

The mechanism of tungsten copper electrode for EDM:

In the process of machining, impulsing power source linked with tungsten copper electrode and work-piece. Generally, the liquid has insulativity (such as kerosene, mineral oil). Tungsten copper electrode is controlled by automatic servo feed regulating system, which ensures the discharging gap (0.01-0.05mm). When the impulse voltage exerted between two electrodes, the liquid medium will be punctured and form discharging channel. The part high temperature melt the material and tungsten copper feed regularly so that the work-piece will be machined as request.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Procedure to Make Tungsten Carbide Cutting Tools Ⅲ

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2015 17:19

In last part we know that to make tungsten carbide cutting tools, we first make tungsten carbide which is a production line from tungsten ore, to sodium tungstate, then to tungsten oxide and then to carbonization. Here we talk about the extreme importance of tungsten carbide grain size.

Grain Size Is Key

The size of the tungsten carbide grains determines the mechanical properties of the final tungsten carbide cutting tools. The size of the grains will depend on the size of the tungsten oxide particles, and how long and at what temperature the oxide/carbon mixture is processed.

The tungsten carbide particles are a fraction of the size of a grain of sand. They are likely to range in size from half a micron, to as large as 10 microns. A series of sieves sorts out the different grain sizes: less than one micron, one and one half microns, and so forth.

At this point, the tungsten carbide is ready for blending into “grade powder.” In the tungsten carbide industry, one speaks of grades rather than alloys, but they mean the same thing.

The tungsten carbide goes into a mixing vessel with the other components of the grade. Powdered cobalt metal will act as the “glue” to hold the material together. Other materials, such as titanium carbide, tantalum carbide and niobium carbide are added to improve the properties of the material when cutting. Without these additives, when cutting ferrous materials, the tungsten carbide cutting tool may experience a chemical reaction between the tool and the chips of the work piece that leaves craters in the tool, especially at high cutting speeds.

(To be continued-This article is divided into several parts and this is part 3, for part 2 please refer to )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Procedure to Make Tungsten Carbide Cutting Tools Ⅱ

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2015 17:15

In last part we know that only decades before, scientists found and used the new material tungsten carbide, first as carboloy, then later added with titanium compound, to make tungsten carbide cutting tools. Here we explain the procedure to make tungsten carbide from tungsten ore.

Start In The Ground

There are several tungsten ores or minerals that can be mined and refined into tungsten or made into tungsten carbide. Wolframite is the best known. The ore is crushed, heated and treated with chemicals (acids or alkalis). The result is tungsten oxide after sodium tungstate. And tungsten oxide are to be treated with hydrogen to get pure tungsten metal powder.

Then, the fine tungsten oxide particles are carburized, turning them into tungsten carbide. In one method, the tungsten oxide is mixed with graphite (carbon). This mixture is heated to over 1200˚ C (2200˚ F) and a chemical reaction occurs that removes the oxygen from the oxide and combines the carbon with the tungsten to yield tungsten carbide.

(To be continued-This article is divided into several parts and this is part 2, for part 1 please refer to http://news.chinatungsten.com/en/tungsten-information/80244-ti-10321; for part 3 please refer to http://news.chinatungsten.com/en/tungsten-information/80247-ti-10323)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Procedure to Make Tungsten Carbide Cutting ToolsⅠ

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 November 2015 17:13

Tungsten carbide, often called simply “carbide”, is a familiar material around the shop. This compound of tungsten and carbon has revolutionized the metal-cutting world over the decades, enabling increased speeds and feeds and providing longer tool life. Tungsten carbide was first investigated as a cutting tool material in 1925, by Dr. Samuel Hoyt, a scientist at General Electric’s Lamp Department. Later GE opened the carboloy division to produce tungsten carbide cutting tools. In the late 1930s, Philip M. McKenna, founder of Kennametal, discovered that adding a titanium compound to the mix made the tools work better at higher speeds. This began the march toward today’s lightning-fast cutting speeds.

“Cemented tungsten carbide,” the material that makes up the tools and inserts, is actually grains of tungsten carbide, along with particles of other materials, cemented together using the metal cobalt as a binder.

(To be continued-This article is divided into several parts and this is part 1, for part 2 please refer to http://news.chinatungsten.com/en/tungsten-information/80245-ti-10322)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com