Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅶ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:50

In last part we know that as the main tool failure mode, flank wear of (Al,Cr)N coated tungsten carbide tool is slower than the (Ti,Al)N coated one. And this part we will get to understand of the wear mechanism of the two coating films on tungsten carbide tools.

Fig. 3 shows the SEM observation and EDS mapping analysis on the worn surface of the (Ti,Al)N coated tungsten carbide tool and the (Al, Cr)N coated tool. Fig.3 (a) shows the details of “A”shown in Fig. 1. Fig. 3 (b) shows the EDS analysis in the case of the oxygen (O) mapping on the cutting part shown in Fig. 1.

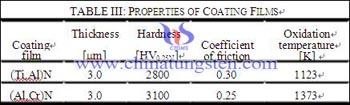

First, as compared with the worn surface of (Ti,Al)N coating film indicated by “B” shown in Fig. 3 i(a) and that of(Al,Cr)N coating film indicated by “B” shown in Fig. 3 ii(a), many striae scratched by a hard material are remarkably found on the worn surface in the case of both the (Ti,Al)N and the (Al,Cr)N coating film. Therefore, the main wear mechanism of both the (Ti,Al)N and the (Al,Cr)N coating film is considered to be abrasive wear. In the case of abrasive wear, the wear-resistance of the coating film often depends on the hardness of the coating film. That is, a coating film with higher hardness has good wear-resistance. So the characteristics of the coating films were investigated. The results are shown in Table III. The thickness of coating of (Al,Cr)N film is 3 μm, which is the same as that of (Ti,Al)N film. The (Al,Cr)N coating is harder than the (Ti,Al)N coating because the wear progress of (Al,Cr)N is considered to be slower than that of (Ti,Al)N.

(To be continued. This article is divided into several parts. Here is part 7 For part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/80627-ti-10436; for part 8 please refer to http://news.chinatungsten.com/en/tungsten-information/80629-ti-10438)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅵ

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:46

In last part we know that after testing, tungsten carbide tools with (Al,Cr)N coating film exhibit much better wear resistance quality than with (Ti,Al)N coating. In this part we will get to a closer analysis of the flank wear feature of the two coated tungsten carbide tools.

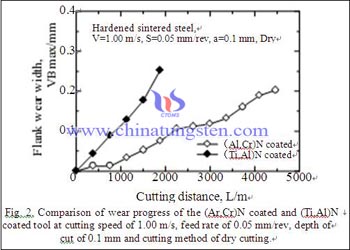

Following these experiments, it emerged that the main tool failure for two kinds of coated tools in cutting hardened sintered steel was the flank wear within a maximum value of the flank wear width of about 0.2 mm. Therefore, the maximum value of the flank wear width (VBmax) was measured by microscope.

Fig. 2 shows the wear progress in cutting two kinds of coated tools at a cutting speed of 1.00 m/s. The wear progress of the (Al,Cr)N coated tool is slower than that of the (Ti,Al)N coated tool. As mentioned above, the (Al,Cr)N coated cemented tungsten carbide tool is an effective tool material in cutting hardened sintered steel, so Scanning Electron Microscopy (SEM) observation and Energy Dispersive X-ray Spectrometer (EDS) analysis were carried out on the worn surface.

(To be continued. This article is divided into several parts. Here is part 6. For part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80617-ti-10434; for part 7, please refer to http://news.chinatungsten.com/en/tungsten-information/80628-ti-10437)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Coating Materials for Tungsten Carbide Drill Bit

- Details

- Category: Tungsten Information

- Published on Monday, 23 November 2015 11:42

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅴ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:50

In last part we know that the tungsten carbide tools PVD-coated with (Ti,Al)N and (Al,Cr)N coating films are tested in cutting hardened sintered steel to compare the effect, since (Al,Cr)N coating film is a new film. In this part we will get result and make analysis.

Results and Discussion

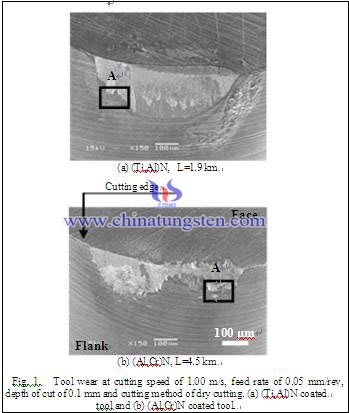

The hardened sintered steel was turned with two kinds of coated cemented tungsten carbide tool at a feed rate of 0.05 mm/rev and a depth of cut of 0.1 mm. Fig.1 shows the SEM observation of the tool wear. Fig.1 (a) and (b) show the case of the (Ti,Al)N coated and the (Al,Cr)N coated tool at a cutting speed of 1.00 m/s, respectively. In the case of the (Ti,Al)N coated tool shown in Fig. 1 (a), a crater is found on the rake face along the cutting edge, and adhesion on both the rake and flank faces is not remarkable either. Also, the flaking of the coating layer is not remarkable. In the case of the (Al,Cr)N coated tool shown in Fig. 1 (b), there is no remarkable crater on the rake face. And adhesion on the flank face is found, while the flaking of the coating layer is also unremarkable.

(To be continued. This article is divided into several parts. Here is part 5. For part 4, please refer to http://news.chinatungsten.com/en/tungsten-information/80616-ti-10433)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅳ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:47

In last part we know that the study is to explore the effectiveness and wear mechanism of tungsten carbide tool with (Al,Cr)N coating film coated by PVD technology in turning hardened sintered steel.This part goes on explaining how the experiments go.

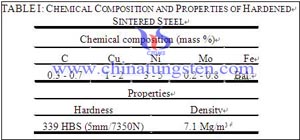

2. Experiment Details

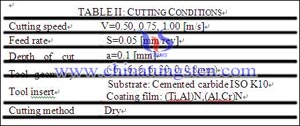

The work material used was hardened sintered steel from diffusion alloyed powder. This material had a density of 7.1 Mg/m3, and many pores were observed when examining the structure by microscope. The chemical composition and the mechanical properties of the hardened sintered steel are shown in Table I. That is, the hardened sintered steel had a hardness of 339 HBS. The cutting conditions are shown in Table II. The tool material of the substrate was cemented carbide, and two types of PVD-coated cemented tungsten carbide tool were used. Namely, the coating films used were (Ti,Al)N and (Al,Cr)N coating film. (Al,Cr)N is a new type of coating film. The configurations of tungsten carbide tool inserts were TNGA160408. The insert was attached on the tool holder MTGNR2525M16. In this case, the tool geometry was (-6, -6, 6, 6, 30, 0, 0.8 mm). The turning tests were carried out on a precision lathe (Type ST5) with an added variable-speed drive. The driving power of this lathe is 7.5/11kW and the maximum rotational speed is 2500 min-1. The tool wear of the two kinds of turning insert was investigated.

(To be continued. This article is divided into several parts. Here is part 4. For part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80615-ti-10432; for part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80617-ti-10434)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅲ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:38

In last part we know that tungsten carbide tools are ideal for machining hardened sintered steel, and the coating film TiN, Ti(C,N) and (Ti,Al)N are already broadly studied. This part goes on explaining why the author choose tungsten carbide tool coated with (Al,Cr)N and hardened sintered steel as study objects.

An aluminum-chromium based coating film, namely (Al,Cr)N coating film, which exhibits a superior critical scratch load, has been developed. The aluminum-chromium based coated tungsten carbide tool was evaluated through the machining of sintered steel, and showed greatly improved performance. However, the effectiveness of the aluminum-chromium coating film is unclear when cutting hardened sintered steel.

In this study, to clarify the effectiveness of aluminum-chromium coating film for cutting hardened sintered steel, tool wear was experimentally investigated. The hardened sintered steel was turned with an aluminum-chromium based coated tungsten carbide tool according to a physical vapor deposition (PVD) method. Moreover, the tool wear of the aluminum-chromium based coated item was compared with that of (Ti,Al)N coated tools.

(To be continued. This article is divided into several parts. Here is part 3. For part 2, please refer to ; for part 4, please refer to )

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅱ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:36

In last part we know that generally (Al,Cr)N coated tungsten carbide tool has a slower tool wear progress because of the coating film has higher hardness and higher oxidation temperature. This part is an introduction of the whole article, explaining why the author choose tungsten carbide tool coated with (Al,Cr)N and hardened sintered steel as study objects.

1.Introduction

A machine part having a complicated shape can be mass-produced accurately by powder metallurgy. A diffusion alloyed powder or a completely alloyed powder is usually used as an alloyed powder for the sintered steel. The compressibility of the diffusion alloyed powder is better than that of the completely alloyed powder. After the sintering, the sintered material is quenched and tempered to improve the mechanical properties and wear-resistance. For dimensional accuracy, it is often necessary for the sintered steel machine parts to be machined by the metal removal process. As the sintered machine parts are often cut at high cutting speed for mass-production, the tool materials must have good wear resistance. The polycrystalline cubic boron nitride compact (cBN) seems to be an effective tool material because it has good heat resistance and wear resistance. However, in milling, a major tool failure of cBN readily occurs by fracture because cBN has poor fracture toughness. Coated cemented tungsten carbide tools, which have good fracture toughness and wear resistance, seem to be effective tool materials. TiN, Ti(C,N) and (Ti,Al)N are generally used for the coating film. So, there are many studies on the wear-resistance of these coating layers. Although there are some studies on the tool wear characteristics of the PVD coated cemented tungsten carbide tools in the cutting of the hardened steel or the sintered steel, there are few studies on tool wear in the cutting of the hardened sintered steel.

(To be continued. This article is divided into several parts. Here is part 2. For part 1, please refer to http://news.chinatungsten.com/en/tungsten-information/80613-ti-10422; for part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80615-ti-10432)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Wear of Coated Tungsten Carbide Tool In Cutting H.S. SteelⅠ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:34

Abstract

In This article, the tungsten carbide tool refers to aluminum-chromium based coated

cemented tungsten carbide too, and H.S. steel refers to hardened sintered steel instead of high speed steel.

The tool life in turning sintered steels is shorter than that in turning melted steels such as carbon steels. In order to identify an effective tool material for cutting hardened sintered steel, tool wear was experimentally investigated. Hardened sintered steel was turned with two kinds of PVD coated cemented tungsten carbide tools. The coating films used were (Ti,Al)N and (Al,Cr)N. The main results obtained are as follows:

(1) The tool wear progress of the (Al,Cr)N coated cemented tungsten carbide tool was slower than that of the (Ti,Al)N coated cemented carbide tool.

(2) Because the (Al,Cr)N coating film exhibited both higher hardness and higher oxidation temperature, the wear progress of the (Al,Cr)N coated cemented tungsten carbide tool became slower.

(3) In cutting hardened sintered steel with (Al,Cr)N coated cemented tungsten carbide tool, there was little influence of the cutting speed on the tool wear within the range of the cutting speed from 0.5 m/s to 1.0 m/s.

(To be continued. This article is divided into several parts. Here is part 1. For part 2, please refer to http://news.chinatungsten.com/en/tungsten-information/80614-ti-10431)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Separation of Molybdenum in Production Process of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 17:49

Ammonium paratungstate (or APT) is a white crystalline salt of ammonium and tungsten, with the chemical formula (NH4)10(H2W12O42)·4H2O.

Ammonium paratungstate is produced by separating tungsten from its ore. Once the ammonium paratungstate is prepared, it is heated to its decomposition temperature, 600 °C. Left over is WO3, tungsten(VI) oxide. From there, the oxide is heated in an atmosphere of hydrogen, reducing the tungsten to elemental powder, leaving behind water vapor. From there, the tungsten powder can be fused into any number of things, from wire to bars to other shapes.

Separation of tungsten and molybdenum in production process of ammonium paratungstate is an important working procedure, but this is always one of difficult technical problems. General flows of various ammonium paratungstate technologies and the basic nature of molybdenum were summarized. Moreover, advantages and disadvantages of each separation method for tungsten and molybdenum in production process of ammonium paratungstate were systematically analyzed. Analysis results indicated that there are many advantages, such as short process flow, small tungsten loss, good molybdenum eliminating effect, simplicity of operation, low environmental pollution, and economy feasibility to eliminate molybdenum by using ion-exchange method. It is precisely because of these advantages, ion-exchange method to eliminate molybdenum has a very good industrial application prospect.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparation of the Visible Light Responsive N 3−-Doped WO 3 Photocatalyst by A Thermal Decomposition of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 17:39

Preparation of the visible light responsive N 3−-doped WO 3 photocatalyst by a thermal decomposition of ammonium paratungstate

Ammonium paratungstate (or APT) is a white crystalline salt of ammonium and tungsten, with the chemical formula (NH4)10(H2W12O42)·4H2O.

Ammonium paratungstate is produced by separating tungsten from its ore. Once the ammonium paratungstate is prepared, it is heated to its decomposition temperature, 600 °C. Left over is WO3, tungsten(VI) oxide. From there, the oxide is heated in an atmosphere of hydrogen, reducing the tungsten to elemental powder, leaving behind water vapor. From there, the tungsten powder can be fused into any number of things, from wire to bars to other shapes.

The nitrogen doped WO3 (N-WO3) photocatalyst was successfully prepared by a thermal decomposition of an ammonium paratungstate [(NH4)10W12O41·5H2O] containing NH4+ ions as a nitrogen source. The N-WO3 prepared at 673–873K efficiently absorbed visible light in longer wavelength regions as compared to a commercial N-free WO3. Although small amount of Pt particles must be deposited on the catalyst surfaces, the N-WO3 photocatalysts were found to decompose gaseous methanol into CO2 and H2O under visible or solar light irradiations. As well as, the Pt particles on the N-WO3 surfaces to enhance the photocatalytic activity showed an oxidation catalysis property at low temperatures of 323–333K. These results suggest that the N-WO3 deposited with Pt particles can effectively utilize the sunlight as light and/or heat sources.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com