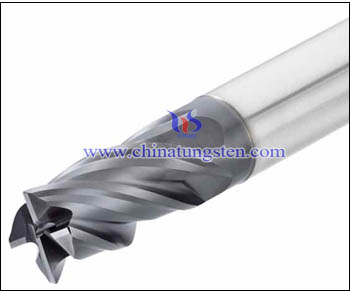

Solid Tungsten Carbide End Mill SystemⅠ

- Details

- Category: Tungsten Information

- Published on Thursday, 29 October 2015 19:01

A basic question often asked when one has both an insert based cutter and a solid carbide cutter is which one is the best and in what areas do they excel? This is not so much a question of one being superior over the other but rather a question regarding the features of a specific type of cutter and how that particular tool should be applied to deliver good results.

An insert milling cutter is different from a solid tungsten carbide milling cutter in many ways. Different types of coatings and different types of substrates are used with solid carbide cutters as compared to insert based systems and that makes for a number of significant feature differences between these two main groups. If some of the features in one of these two groups becomes more important in a certain application, then that tool is perhaps more suitable for the application.

Tolerances on both tools can be equally narrow, statically, but since solid carbide as a material is much stiffer compared to a steel shank tool with a mounted insert, it is prone to less bending and thus has a higher level of precision under the influence of cutting forces during machining.

Another important fact to remember is the arc of tool contact. The arc of tool contact or in other words the length of the circumference of a particular tool that is in contact with a machined part is directly linked to the amount of heat that is generated and absorbed into the tool, component or chips.

(To be continued. This article is divided into several parts and this is part 1, for part 2 please refer to ; for part 16 please refer to )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com