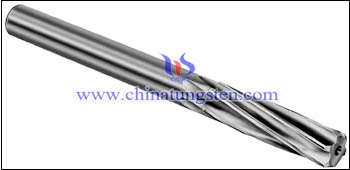

Tungsten Carbide Reamer Ⅲ

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 October 2015 14:25

In part 2 we know that a tungsten carbide reamer usually consists of cutting edges with a slight undercut below each, a cylindrical body partly as the shank, and mostly preferred clockwise spiral, and the shanks have also different types for respective purpose.And here we reveal the different effect of reaming and drilling in making hole size.

Difference of reaming and drilling in sizing

The geometry of a hole drilled in metal by a twist drill may not be accurate enough (close enough to a true cylinder of a certain precise diameter) and may not have the required smooth surface finish for certain engineering applications. Although modern twist drills can perform excellently in many cases—usually producing sufficiently accurate holes for most applications—sometimes the stringency of the requirements for the hole's geometry and finish necessitate two operations: a drilling to slightly undersize, followed by reaming with a tungsten carbide reamer. The planned difference between the drill diameter and the reamer diameter is called an allowance. (It allows for the removal of a certain small amount of material.) The allowance should be < 0.2 mm (.008 in) for soft materials and < 0.13 mm (.005 in) for hard materials. Larger allowances can damage the reamer. The drilled hole should not be enlarged by more than 5% of the drilled diameter. Drilling followed by reaming generally produces hole geometry and finish that is as close to theoretical perfection as possible. (The other methods of hole creation that approach nearest to perfection under certain conditions are boring , especially single-point boring] and internal cylindrical grinding.)

(To be continued. This article is divided into several parts and this is part 3, for part 2 please refer to http://news.chinatungsten.com/en/tungsten-information/79457-ti-10166; for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/79531-ti-10169)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com