Failure Modes of Tungsten Carbide Cutters Ⅶ

- Details

- Category: Tungsten Information

- Published on Thursday, 15 October 2015 14:56

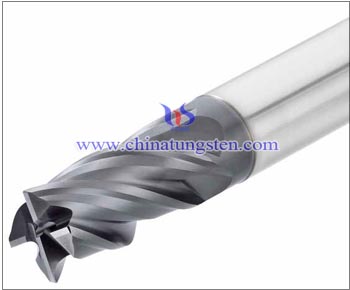

In part 6 we know that catering failure happens when the tungsten carbide cutter’s surfaces are stricken by particulate-bearing liquid or gas, especially when the operating temperatures are much higher and the more fine-grained the carbide is, the easier for the failure to occur.. In this part we will talk about adhesion wear/galling as another failure mode.

7. Adhesion wear/galling

Adhesion wear occurs when a tungsten carbide cutter’s surface and that of a mating part or the work material rub together or slide past each other with sufficient force to create excessive friction and pressure at high points of contact between the materials. The high temperatures and pressures generated in these contact zones result in plastic deformation at the material surfaces, penetration of one surface by the high points on the other, and finally the transfer of material (welding) of one material to the other. As material builds up on one of the surfaces, the still higher points of contact create more heat, leading to more deformation, penetration, and material transfer. This process is often referred to as “galling”. Failure by adhesion wear can take several forms, but typically the buildup reaches a stage where it eventually is dislodged pulling chunks of the carbide surface with it.

(To be continued. This article is divided into 9 parts and this is part 7, for part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/79384-ti-10152)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com