Cemented Carbide Blades Wear Characteristics In Drilling LimestoneⅤ

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 September 2015 10:36

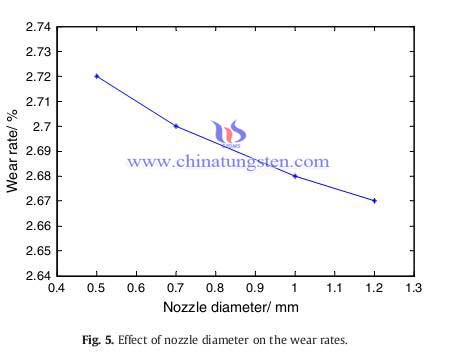

3.2. Effect of the nozzle diameter on the wear rates of the cemented carbide blades

Bigger nozzle diameter means larger impact area and more impact force to the limestone, which helps to reduce the mechanical force on the blade and lessen the wear of it. Fig. 5 summarizes the effect of nozzle diameter on the wear rates of the cemented carbide blades under the water pressure of 30 MPa. It is showed that wear rates decrease with the increasing of the nozzle diameter of the drill bit.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Vacuum Smelting Process for Producing Ferrotungsten-Description IX

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 September 2015 09:45

The heating of the pelletized charge to within the desired temperature range is achieved at a rate as quickly as possible without incurring fracture or rupture of the pellets due to the rapid gasification of any moisture and other volatile constituents therein including the binder constituent, thereby producing pellets of a porous nature which become progressively more porous as the vacuum smelting reaction proceeds until a temperature is attained at which some sintering and densification of the pellets occurs. When iron oxide is employed in the pelletized feed stock as the source of the iron-bearing material, the reduction of iron oxide takes place commencing at a temperature of about 1800° F. and is accompanied by a liberation of carbon monoxide gas. A reduction of the tungsten oxide constituent takes place commencing at a temperature of about 1800° F. and the reaction itself is carried out for a period of time sufficient to effect a substantially complete reduction of the tungsten oxide constituent and of any iron oxide present to the metallic state. As metallic tungsten is produced during the course of the vacuum smelting reaction, the initial iron constituent present or the metallic iron produced by the reduction of the iron oxide constituent becomes alloyed with the tungsten, producing a nonsegregated substantially dense pellet of ferrotungsten alloy. Upon completion of the vacuum smelting operation, the pelletized charge is permitted to cool to a temperature below about 300° F. whereafter the dense ferrotungsten alloy product can be extracted and exposed to air such as by back-filling the vacuum smelting furnace and the product recovered.

In order to further illustrate the process comprising the present invention, the following examples are provided. It will be understood that the examples hereinafter set forth are provided for illustrative purposes and are not intended to be limiting of the invention as herein described and as defined in the subjoined claims.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Vacuum Smelting Process for Producing Ferrotungsten-Description VIII

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 September 2015 09:43

During the vacuum smelting operation, other constituents which are also volatilized and removed from the pelletized feed stock to effect a purification of the resultant ferrotungsten alloy residue include: silica, iron and iron compounds, calcium compounds, manganese and manganese compounds, aluminum compounds, lead compounds and other oxygen-containing compounds, as well as other conventional impurities normally found in ore deposits containing tungsten. The substantial reduction in the content of such contaminating constituents renders the resultant ferrotungsten alloy briquettes eminently suitable in many instances for direct use as metallurgical alloying agents in steel-making operations and the like without any further purification. A typical composition of ferrotungsten alloys, including permissible amounts of various contaminating constituents in accordance with ASTM specifications are as follows:

______________________________________

Tungsten 72.0 - 82.0% Carbon 0.60 max. Phosphorous 0.060 max. Sulfur 0.060 max. Silicon 1.00 max. Manganese 0.75 max. Copper 0.10 max. Arsenic 0.10 max. Antimoney 0.080 max. Tin 0.10 max. Total arsenic, antimony and tin 0.20 max. Iron Balance

______________________________________

The ferrotungsten pellets produced can be suitably packaged in steel containers providing premeasured quantities of the ferrotungsten alloy, and in that form can be utilized in steel-making and foundry operations.

The temperature of the pelletized feed stock during the vacuum smelting operation may range from as low as about 2500° F. to as high as about 3100° F. and preferably is controlled within a range of from about 2700° F. to about 2900° F. Temperatures below about 2500° F. are commercially unsatisfactory due to the slow rate of reduction of the tungsten oxide constituent, while on the other hand, temperatures above about 3100° F. are undesirable because of excessive costs of refractories required in the vacuum smelting furnace. The vacuum smelting operation is carried out at pressures less than about 0.5 Torr and preferably at pressures less than about 0.05 Torr (50 microns) to as low as about 0.001 Torr (1 micron) and even lower, depending upon the limitations of the vacuum equipment employed. Particularly satisfactory results are achieved when the pelletized charge is heated at a temperature ranging from about 2800° F. to about 3100° F. employing a vacuum ranging from about 0.05 Torr to about 0.001 Torr.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Blades Wear Characteristics In Drilling Limestone Ⅳ

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 18:53

3. Results and discussion

3.1. Effect of water jet pressure on the wear rates of the cemented carbide blades

Fig. 4 shows the wear rates of cemented carbide blades under different water jet pressure (the used diameter of the water jet nozzle is 1.2 mm). It is shown that the wear rate is quite high (nearly 10%) without the help of water jet, but the wear rates decrease sharply when the water jet joins in. The wear rates decrease when the jet pressure increases. Nevertheless, the wear rate decrease slowly when the jet pressure is over 10 MPa.

The wear rates are affected by the mechanical stress and temperature of the blades, and the water jet is helpful to reduce the mechanical stress and temperature. The more impact stress the water

jet gives to the rock, the less mechanical stress is on the blades. The maximum impact stress of the water jet on the rock (Pi) is given by the Eq. Pi=v*ρ1*c1*ρ2*c2/(ρ1*c1+ρ2c2)

where v is the jet velocity of the liquid and ρ1, ρ2 and c1, c2 are the densities and the shock velocities in the liquid and the solid. According to the equation, the impact stress will increase with the jet velocity. The relationship between jet pressure and velocity could be estimated by the expression, where P is jet pressure. So the impact stress will increase with the jet pressure: bigger jet pressure means lower mechanical stress on the blade.

Higher jet pressure could also increase the thermal exchange efficiency to reduce the working temperature. Heat transfer takes place when the water jet flows through the surface of blade, with a cooling effect. This cooling process can approximately be regarded as the process of convective heat transfer outside flat plate. The surface heat transfer coefficient of the blade will be, where h is the heat transfer coefficient of the surface, λ is the coefficient of thermal conductivity of water, l is the flow length on the blade, ξ is the kinematic viscosity of water, μ is the dynamic viscosity of water, Cp is the specific heat capacity of water. The power of heat exchanging is given by Eq. where Φ is the power of heat exchanging, TH is the temperature of blade, TL is the temperature of water, S is the area of flow on the blade.

In a word, the cooling effect is proportional to the square root of jet speed v, and according to Eq. (3) , it is also proportional to the forth root of jet pressure P.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Blades Wear Characteristics In Drilling LimestoneⅢ

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 18:33

2. Materials and experimental procedures

2.1. Materials

The blade material of drill bit is WC/Co cemented carbide YG6 (6%Co, 94%WC), whose mechanical properties are listed in Table 1. The installation of the blade and water jet nozzle are shown in Fig. 1. The sizes of the blades are listed in Table 2.

Limestone (taken from Songzao Mine in southwest China) is drilled as hard rock material in the experiment. The properties of the limestone are listed in Table 3, and the SEM micrograph of it is shown in Fig. 2

2.2. Experimental procedures

The experiments were performed at room temperature. The drill rig kept the drilling speed at 120 mm/min and rolling speed at 70 rounds/min for 30 min in the experiments, which aimed to investigate the influence of different water jet parameters (jet pressure, nozzle diameter) on the wear characteristics of the cemented carbide blades(m0):R=mx/m0

The weight of blades was measured with a balance (minimum 0.01 mg) made by Mettler Toledo. For the determination of wear mechanisms, the wear surfaces were analyzed by scanning electron

microscope made by TESCAN

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Blades Wear Characteristics In Drilling LimestoneⅡ

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 18:13

Water jet is a liquid beam with high velocity and pressure, and is used singly or jointly with tools for operations such as cutting, shaping and carving. Since water jet system is simple and the cost is not very expensive, it is widely used in metal machining and medical operation. Cemented carbide is the dominant material in machining and mining tools for its unique combination of hardness, toughness and inexpensive price. However, the cemented carbide tool damaged seriously in hard rock drilling. If water jet is used to assist the drill bit, it could impact the rock to reduce the blade force and exchange the heat to cool the blade temperature therefore, it would be an effective way to improve the work life of the cemented carbide blade when water jet is used in rocking drilling .

Various failure mechanisms of ordinary cemented carbide drill bits in rock drilling are studied. Beste charts the wear phenomena of cemented carbide rock-drill bits, such as crack formation, occurrence of reptile skin and various wear mechanisms. Stjernberg reports that the drilling process produces temperature fluctuations in the surface region, which leads to high tensile stresses and accelerates the forms of cracks. In Montgomery's survey, the minimum wear rate of cemented carbide in granite drilling occurs at a specific hardness point, which corresponds to the point of maximum compressive strength, and there are also other reports on investigating the wear process of drill bit in rock drilling. Lots of literatures have shown that cemented carbide exhibits strong life time-limiting fatigue sensitivity at room temperature. But Kindermann reported the fatigue mechanisms in cemented carbides are strongly temperature-dependent. At higher temperatures, the oxidation of the binder ligaments near crack tips and brittle –ductile transitions of mixed carbides seem to play an important role in the fatigue behaviors. In addition, the service temperatures of the tools rise much higher than the room temperature and influence their working lives. The service temperatures of rock drilling bits are estimated to lie between 300 and 500°C. In tests with WC/Co sliding against sandstone, a glassy phase is produced which indicates flash-temperatures of 1250°C or more. Oxidation behavior of the cemented carbide bits will occur in rock drilling , and the mechanical properties will be influenced.

Although water jet seems to be a good way to solve the above problems, but the wear of the cemented car bide blades in hard rock drilling under water jet is a dynamic process, whose wear mechanisms and patterns are not well characterized or understood. Moreover, little work has been published on the wear characteristics of t he cemented carbide blades in drilling hard rock with water jet.

The goal of this work was to investigate wear characteristics of the cemented carbide blades in drilling hard rock with water jet. Limestone is a typical hard rock in the practical engineering applications. In this paper, the wear rates of cemented carbide blades under different water jet parameters in limestone drilling were measured, and the wear mechanisms of these cemented carbide blade in limestone drilling with water jet were examined with microstructure analysis of the wear surface.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Blades Wear Characteristics In Drilling LimestoneⅠ

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 18:10

Drilling hard rock with water jet is considered to be an efficient way to improve the work life of the cemented carbide blade. In this paper, cemented carbide material YG-6 is used on the drill bit in limestone drilling with water jet. Wear characteristics of the cemented carbide blades in drilling limestone with water jet is studied. Experiment results showed that the water jet pressure and nozzle diameter played an important influence on the wear rates of the cemented carbide blades in the drill bits.

The wear rates of YG-6 blades decreased when the jet pressure increased. But the decline speed of wear rates was not eve n, it declined more and more s lowly when t he jet pressure upon 10 M Pa. It w as also showed that wear rates decrease with the increase of the nozzle diameter in the drill bit , for the bigger nozzle diameter could provide more impact force which could reduce the mechanical force on t he YG-6 b lades. SEM photographs were taken to characterize the wear mechanism of the cemented carbide blades in limestone drilling with water jet. Surface analysis demonstrated that cemented carbide blades in limestone drilling with water jet showed circular action of brittle fracture, grain pullout and polishing, which induced material removal process.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Football Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 18:02

Football tungsten dart rule is a fun game for two teams of 1-4 players. The rules are very simple, but the game is quite challenging.

The Object: The object is to be the first to score a predetermined number in a manner similar to American football.

The Scoring: One player from each team throws one dart a bulls-eye, closest to the bulls-eye goes first. The team names are written on the board in order and a 0 placed next to each name to indicate the current score. The teams pick a side of the board to be their "goal line", either 11 or 6.

The Play: Each team has four "downs" to try to move the ball across the board and into their opponent’s goal. Each down consist of three darts thrown and players on the team alternate for equal opportunity to play.

The playable area of the board is the Double-11, Large-11, Triple-11, Small-11, Bulls-eye, Double-Bulls-eye, Bulls-eye, Small-6, Triple-6, Large-6 and Double-6. One team’s goal line is the Double-11 and the other team's goal line is the Double-6. The Double-Bulls-eye is the "50 yard line".

The first team starts at their own goal line, for example Double-6. They try to hit one dart in each number in order across the board. The team plays all 4 of it downs (a total of 12 darts) in a row to try to move the ball as far across the field as possible. At the end of the 4 downs, the other teams "takes possession of the ball" where the original team left it and has 4 downs to try to move it back across the goal line.

If a team scores a goal (sequentially hitting all the target numbers across the board ending in the other team's goal line {the double 6 or 11}) that team earns 6 points and has an opportunity to throw for an extra point. An extra point is scored by throwing one dart in the 20.

After a goal is scored, the other team takes possession of the ball in its own goal regardless of how many darts or downs the scoring team had left.

.

Strategy: Take your time and concentrate on the bulls-eyes. They are hard to hit, but once you get across, it's all down hill and the other team has to get the ball back across.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Futbol Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 17:58

Futbol tungsten dart rule is kind of an odd game that really sharpens your ability to hit bulls-eyes. This game can be played with 2 players or 2 teams.

The Object: To score at least the same number of points faster than your opponent was able to.

The Scoring: Four tallies are marked each side of the board to represent the four "downs" that the offense possesses the ball. The player’s names are written at the top of each column.

The Play: Both players throw one dart at bulls-eye, closest to the bull throws first and the option of "receiving the ball". If the player "receives" he will play offense first and try to score points. If the player chooses not to receive he will play defense and try to stop the other player from scoring too many points.

The offensive player throws first and tries to score as high a score as possible with three darts. The thin outer ring is the "double" and counts as two time the number scored. The thin inner ring is the "triple" and counts as three times the number scored. Any score 41 or greater is added to the offensive player's score.

Next, the defensive player throws three darts at bulls-eye. Any darts that hit the bulls-eye remove one down each (two if it is a double bulls-eye). Erase one tally from the offensive player's side for each bulls-eye the defense scored.

Play continues alternating players until the defense has removed all four downs from the offensive player. Once all four downs are removed, "possession of the ball" is turned over to the original defensive player. The offensive player now plays defense and the defensive player now plays offense.

The goal of the new offensive player is to score more points than the original offensive player scored.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Vacuum Smelting Process for Producing Ferrotungsten-Description VII

- Details

- Category: Tungsten Information

- Published on Monday, 07 September 2015 17:56

In accordance with a typical processing sequence, the tungsten containing particulated mineral concentrate is blended with an appropriate quantity of a powdered carbonaceous reducing agent in addition to a desired quantity of supplemental iron powder and/or iron oxide, whereafter appropriate quantities of binder are added. The resultant mixture is agglomerated into pellets of the desired size and shape and the green pellets are subsequently dried and transferred to a pellet storage hopper. The resultant pellets can be charged to a vacuum smelting furnace either on a batchwise basis or on a continuous basis, as may be desired, to effect a heating thereof to an elevated temperature in the absence of oxygen and under a relatively high vacuum so as to effect a direct reduction of the tungsten oxide constituents and any iron oxide constituents present and an extraction of the volatile contaminating constituents including the gaseous reaction products of the oxidized carbonaceous reducing agent, such as in the form of carbon monoxide. The vacuum furnace may suitably be evacuated employing a vacuum pump which preferably is of a steam ejector type and also effects a transfer of the vaporized constituents through suitable condensers for effecting a selected recovery thereof as by-products.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com