Cemented Carbide Blades Wear Characteristics In Drilling LimestoneⅤ

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 September 2015 10:36

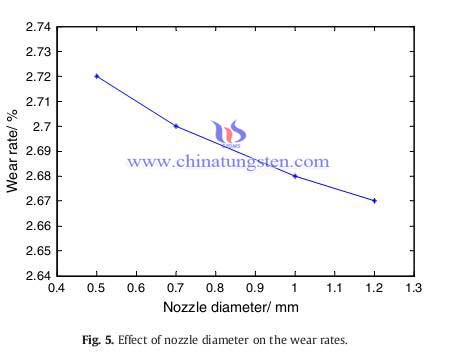

3.2. Effect of the nozzle diameter on the wear rates of the cemented carbide blades

Bigger nozzle diameter means larger impact area and more impact force to the limestone, which helps to reduce the mechanical force on the blade and lessen the wear of it. Fig. 5 summarizes the effect of nozzle diameter on the wear rates of the cemented carbide blades under the water pressure of 30 MPa. It is showed that wear rates decrease with the increasing of the nozzle diameter of the drill bit.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com