Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅳ

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:32

2.2 Coating evaluation

The thickness of TiN coatings and interlayers was measured using a stylus ( α -ST EP) instrument and a scanning electron microscopy (Hitachi,S-4200). Hardness was determined using microhardness tester with Knoop indenter (Matsuzaw a, MMT-7) under a load of 25 g. The adhesion behavior between TiN coatings and WC-Co substrate was investigated with a scratch tester (J& L Tech , Scratch test JL ST022) using a Rockwell C diamond stylus (cone apex angle: 120°; tip radius: 200 μ m). During the scratch test, the stylus load was increased continuously up to 150 N with a loading rate (d L/d t ) of 3 N/s and a translation speed of 0.2 mm /s. The friction force (FF), friction coefficient (FC ) and acoustic emission (AE) signals were recorded. These investigations were complemented by observation of scratch track with the optical and SEM microscope (Olympus, PMG3-613U W/A cc) examination and a scanning electron microscope.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅲ

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:25

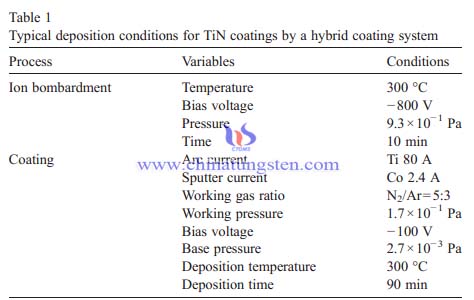

TiN coatings were deposited onto WC-Co substrate by a hybrid coating system, where an arc ion plating (AIP) method was combined with a magnetron sputtering technique. The schematic diagram of the apparatus was depicted in previous work . The WC-Co substrates with WC particle size of 0.7 μm and Co content of 10 wt. % were machined into disc types of 25 mm in diameter and 3 mm in thickness. The substrates were thoroughly cleaned in an ultrasonic bath cleaner using acetone and alcohol for 20 min. Prior to deposition, the substrates were cleaned again by ion bombardment using a bias voltage of − 800 V under Ar atmosphere for 10 min. Thin Co interlayer with various thicknesses were pre-deposited on the substrate by a d.c. magnetron sputtering technique using high purity (99.99%) Co targets. The interlayer thickness was controlled by sputtering time considering our back-data of thickness vs. sputtering time, where the thickness was measured with a stylus (α -STEP) and SEM. Right after pre-deposition of the interlayer, The TiN was coated with thickness o f ∼ 2.5 μm using an AIP technique. The typical deposition conditions are summarized in Table 1. The post annealing of samples was carried out at temperature range from 200 °C to 600 °C for 2 h in a vacuum chamber. The purity of used Ar and N2 gases was 99.999%.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Nationalist Government's Attempts and Success in Monopolizing Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 17:56

The Nationalist government first contemplated a monopoly on tungsten ore in 1930,since it was extremely important as a rare material for military-related industries and the free tungsten market was in total chaos at the time. However,its initial efforts failed due to resistance and hindrance on the part of local forces. In 1933,China and Germany joined hands in a barter trade arising out of their mutual needs. The Nationalists took tungsten as a key material in exchange for military-related industrial equipment from Germany in preparation for a war against Japanese aggression. The state monopoly over tungsten ore soon gained a special position. It was established before the war,through tough negotiations with provincial governments in Guangdong and other provinces. The monopoly was more significant in political than in economic terms. It played an important role in preparation and actual support for the war against Japanese aggression,and in integration of the central and local governments.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Resources Prediction of Xianglu Mountain Based on MapGIS

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 17:54

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Diddle for Middle Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 17:42

Diddle for Middle tungsten dart rule is a difficult game similar to x01. It is intended for two players of intermediate to advanced ability.

The Object: To be the first to score exactly 501 beginning and ending with a double.

The Scoring: Playing order is determined by a throw of one dart each at bulls-eye, closest to the bulls-eye goes first. The names are written in order at the top of the board with the number 501 in between. A vertical line divides the board into columns for each player.

The Play: Each player must "double-in" before any score may count for the game. This means you must hit any double around the board and only the double and any tungsten darts thrown after the double count toward your score.

After the initial double is hit, the only areas the count for scoring are inside (but not including) the thin inner "triples" ring. Players aim at the bulls-eye and double-bulls-eye to try and score 25 or 50 points respectively with each dart. Any tungsten darts that land in the small inner wedge between the bulls-eye and the triples ring counts as the number hit. The score of the three tungsten darts is totaled and subtracted from the player current score.

When the player get to 50 or below, the player must throw a double to end exactly on zero. For example, if the player has 38 points left, the player must throw a double-19 to win the game. If the player scores more than the number of points left it is called a "bust" and all tungsten darts thrown that round do not count; that is the score remains the same.

Strategy: Try to always leave yourself on an even number so you can get your double-out easily. If you have an odd number you will have to throw an extra tungsten dart to get even before trying your double.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Fifty-One in 5's Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 17:40

Fifty-One in 5's tungsten dart rule is a really fun game that may be played by any number of players. However, do not try to teach this game to anyone who has trouble with the math in x01 or someone who is drunk (not that dart players ever drink). This game requires more thought about each throw than most.

The Object: Be the first player to reach a score of exactly 51.

The Scoring: Players names are written across the top of the board in playing order. Order is usually determined by throwing one tungsten dart at bulls-eye each, closest to the bulls-eye shoots first.

A running total is kept vertically below each player's name to show the current score he or she has.

The Play: Each player throws three tungsten darts trying to score a total of the three tungsten darts that is exactly divisible by 5. If the player's total is not divisible by 5, all three tungsten darts do not count.

If the player's total is exactly divisible by 5, divide the total by 5 and that number is the score for the round. For example, a player throws a single 20, a single 20 and a single 5. The score for that player would be 9 (20+20+5=45 45/5=9).

If any one dart misses the board entirely, all three tungsten darts thrown in that round do not count.

To win the game, a total of 51 must be hit exactly. If the total ends up more than 51, all three of the tungsten darts thrown in that round do not count and the score remains the same.

Strategy: The two best places on the board to throw are at the 20/5 area or the 10/15 area. Each of these areas give a nice wide target where hitting either number leaves you divisible by 5.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball National Standard

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 17:09

The priority of tungsten carbide ball diameter Dw(mm) table:

|

Nominal diameter Dw of tungsten carbide ball(mm) |

||

|

0.5 |

9 |

38 |

|

0.8 |

10 |

40 |

|

1 |

12 |

42 |

|

1.5 |

14 |

44 |

|

2 |

16 |

46 |

|

2.5 |

18 |

48 |

|

3 |

20 |

50 |

|

3.5 |

22 |

52 |

|

4 |

24 |

54 |

|

4.5 |

26 |

56 |

|

5 |

28 |

58 |

|

5.5 |

30 |

60 |

|

6 |

32 |

65 |

|

7 |

34 |

70 |

|

8 |

36 |

75 |

|

If need other diameters,the customer can negotiate with the manufactory directly. |

||

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Grinding Mechanism

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 17:06

Tungsten carbide ball grinding diagram below, which shows that the processing is between two cast iron lapping plates. And there is V-shaped groove on the under plate, which the groove angle is generally 60°or 90°. The material of rotation plate is the same, and the next turn plate rotation drive tungsten carbide ball trenches friction and rotational torque in the rotation and orbital motion testimony. Tungsten carbide ball contacts the groove of the grinding plate with three-point or three-line, which contact with the rotating plate driven ball as to be parallel to the axis of rotation of the grinding plate motion.

Due to the differences of line speed and the contact pressure, the contact points with the groove (line) to drive the ball as perpendicular to the axis of rotation of the grinding plate motion. The size of the spin angular groove angle is related to the shape, the angle of the groove and the rotating speed of grinding plate, which directly affects the efficiency and the machining accuracy of tungsten carbide ball grinding.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How To Correctly Use Cemented Carbide Drill BitsⅡ

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 09:44

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How To Correctly Use Cemented Carbide Drill BitsⅠ

- Details

- Category: Tungsten Information

- Published on Thursday, 10 September 2015 09:33

Cemented carbide is widely used as solid carbide cutting tools, such as drill bits. Correctly use cemented carbide drill bits, to turn material resources to good account,is a mechanical processing practitioner’s responsibility.

How to correctly use cemented carbide drill bits? It mainly includes the following aspects:

1.Choose the right machine tool

Cemented carbide drill bits can be correctly used in those machine tools with high power and good rigidity, such as CNC machine tool and machining center. Radial drill and universal milling machine should not be chosen due to the low power and poor precision of the spindle, which are easily lead to early collapse of the cemented carbide drill bits.

2.Choose the right tool holder of cemented carbide drill bits

If you want to correctly use cemented carbide drill bits, collet chuck, side handle and hydraulic chuck can all be used as tool holder. For quickly change chuck, because the clamping force of it is not enough, you should rather not choose it.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com