Gold And Tungsten Gold-plated "Rusty" Solution Measures

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 16:06

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Radiation Shielding Door(2/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 16:04

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

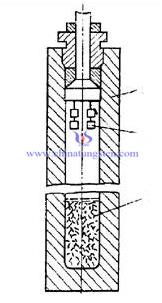

Tungsten Alloy Radiation Shielding Door(1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 16:01

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

High Velocity Oxyfuel Spraying Producing Tungsten Carbide Based Coating Analysis

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 14:28

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Using High Velocity Oxyfuel Spraying to Produce Tungsten Carbide Based Coating

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 14:20

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Hydrothermal Synthesis Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 10:26

Hydrothermal method was invented by the geologist simulating the natural mineralization in mid-19th century and later turned to study functional materials. Currently hydrothermal method has prepared hundreds of kinds of crystals. Hydrothermal method, also known as hydrothermal method, is the scope of liquid chemical method. It means in a sealed pressure vessel, carriing out at high temperature and pressure conditions of the chemical reaction. Hydrothermal reaction depends on the type of reaction and it can be divided into hydrothermal oxidation, water and heat reduction, hydrothermal precipitation, hydrothermal synthesis, water hot solution, hydrothermal crystallization.

Hydrothermal method was invented by the geologist simulating the natural mineralization in mid-19th century and later turned to study functional materials. Currently hydrothermal method has prepared hundreds of kinds of crystals. Hydrothermal method, also known as hydrothermal method, is the scope of liquid chemical method. It means in a sealed pressure vessel, carriing out at high temperature and pressure conditions of the chemical reaction. Hydrothermal reaction depends on the type of reaction and it can be divided into hydrothermal oxidation, water and heat reduction, hydrothermal precipitation, hydrothermal synthesis, water hot solution, hydrothermal crystallization.

The Main Steps:

1. Dissolving the 3.5gNa2WO4•2H20 in 20ml of distilled water, dubbed the solution;

2. Exchanging resin column to produce hydrated tungstate sol by the solution that was hydrated;

3. Stirring constantly the dropped sol with a volume of 70ml glass barrel;

4. Adding to the resulting sol, and mixing well under 4.84g of citric acid.

Conclusions:

Preparing quadrature phase WO3 nano-sized rectangular sheets by hydrothermal synthesis with citric acid as a controlling agent, which shows there is a great relationship between the structure of product and the reaction temperature. X-ray diffraction results show that the reaction product is a WO3 • H2O and a small amount of monoclinic WO3 (γ- WO3); with the reaction temperature, the product of the following occurs transition: WO3 • H2O → WO3. SEM results showed that the product obtained are rectangular sheet structure at the reaction temperature. They are less than the surface area, between 8 ~ 9 m2 • g-1. We can control the product's composition, morphology and specific surface area by adjusting the citric acid and the amount of substance ratio (nCit / nTA). When nCitn / TA = 0, the product of h-WO3 and WO3 • 1 / 3H2O is composition; when nCit / nTA = 0.5 and nCit / nTA = 1, the product is γ-WO3 morphology rectangular sheet. In the case of citric acid was added, than the surface area of the product decreases with an increase of nCit / nTA.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

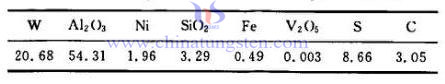

Waste Tungsten-Nickel Catalyst Preparing Sodium Tungstate 2/2

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 19:13

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Waste Tungsten-Nickel Catalyst Preparing Sodium Tungstate 1/2

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 19:11

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium Tungstate Spectrophotometry Determining Gingko Flavonoids

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 19:07

This article mainly introduces a new method-spectrophotometry. Spectrophotometry is determining absorbance of light or luminous intensity of the material tested at a particular wavelength or within a certain wavelength range to make the qualitative and quantitative analysis of the material. The method is based on gingko flavonoids reacting with sodium tungstate to generate yellow tungsten acid ester. This method is highly sensitive, simple, fast, and reliable. If it can be used for the determination of actual samples, a satisfactory result will be got.

This article mainly introduces a new method-spectrophotometry. Spectrophotometry is determining absorbance of light or luminous intensity of the material tested at a particular wavelength or within a certain wavelength range to make the qualitative and quantitative analysis of the material. The method is based on gingko flavonoids reacting with sodium tungstate to generate yellow tungsten acid ester. This method is highly sensitive, simple, fast, and reliable. If it can be used for the determination of actual samples, a satisfactory result will be got.| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gold And Tungsten Gold-plated "Rusty" Reasons

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 18:23

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com