Tungsten Trioxide Compounds Adipic Acid

- Details

- Category: Tungsten Information

- Published on Friday, 15 January 2016 15:56

Adipic acid is also known as fat acid, it is an important organic dicarboxylic acid, it can occur salt, esterification, amidation reaction, and can compound the diamine or diol condensation into high molecular polymer. Adipic acid slightly solubles in water, its solubility has large changes in water. When the solution temperature from 28 ℃ rises to 78 ℃, the solubility can increases to 20-fold. Adipic acid is dicarboxylic acids of great significance in the industry; it has an important role in chemical production, organic synthesis industry, medicine, manufacturing, and other lubricants. Adipic acid is mainly used as raw material for nylon and engineering plastics, but also for the production of esters products, also used as a raw material of polyurethane elastomer, a variety of food and beverage acidulant, and its role may be worth citric acid and tartaric acid. Adipic sour is soft and durable in a wide concentration range of pH change; it is the preferred pH modifier.

Steps

Adding 0.5806g tungsten trioxide, 44.5ml hydrogen peroxide into a 100ml reaction flask. Stirring at room temperature for 10min, then adding 10.5ml cyclohexene (about 100ml, hydrogen peroxide / cyclohexene about 4.4 mole), controlling oil bath heating temperature at 120 ℃, the initial reaction temperature is 75-80 ℃, the latter part of is 95-100 ℃. After completion of the reaction at 85 ℃ under reduced pressure, the separated catalyst becomes tungsten trioxide, and the resulting solution was filtered and allowed in an ice water bath 0.5h. We can obtain adipic acid when the reaction flask is precipitated as adipic acid crystals by vacuum filtration at room temperature.

Conclusions

1. The results shows that the conditions of optimal reaction are: the amount of tungsten trioxide is 5.0mmol, the reaction time is 6h, the rate of adipic acid separation reaches the maximum 75.4 %, and the purity of adipic acid purity is 99.8%.

2. When the amount of tungsten trioxide is 1.25mmol in the solution, there are not products in active centers. With the increasing of the amount of catalyst, an acidic solution is higher; the corresponding increases in the number of active centers.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Acid-Base Titration Determines Tungsten Trioxide Content

- Details

- Category: Tungsten Information

- Published on Friday, 15 January 2016 15:44

For a long time, the determination of high levels of tungsten ore and tungsten trioxide content is generally used in the gravimetric method. Such method has a certain degree of accuracy, but it is also affected by a number of interfering elements. What is more, the process of it is slow, and the need to use expensive platinum dish. The method of acid-base titration assay is simple, rapid compared with a net separating interfering element, eliminating the difficult separation of molybdenum, niobium, tantalum, etc.; it can be applied to high levels of scheelite and analysis of wolfram ore.

Acid-base titration method is based on water to proton transfer reaction; it is also a method of utilizing the capacity analysis. Taking acid as titrant base can measure alkali, and measuring acid by taking alkali as titrant base, this is an extremely versatile method of analysis. The most commonly used standard solution is hydrochloric acid, nitric acid and sulfuric acid is also sometimes used. Acid-base titration is very important in industrial and agricultural production and medical and health.

Acid-base titration method is based on water to proton transfer reaction; it is also a method of utilizing the capacity analysis. Taking acid as titrant base can measure alkali, and measuring acid by taking alkali as titrant base, this is an extremely versatile method of analysis. The most commonly used standard solution is hydrochloric acid, nitric acid and sulfuric acid is also sometimes used. Acid-base titration is very important in industrial and agricultural production and medical and health.

In the determination of the content of the tungsten trioxide, firstly, reacting grease with an ethanol solution of potassium hydroxide, and then dropping back to an excess of potassium hydroxide with hydrochloric acid. We take tungsten trioxide content as a base amount basis in order to calculate the consumption of 1 g of tungsten trioxide milligrams of potassium hydroxide. We determine the content of the mixture of tungsten trioxide with hydrochloric acid, taking phenolphthalein as an indicator, titration with hydrochloric acid, and then adding methyl orange indicator, the consumption of the difference between the volumes of hydrochloric acid is the content of tungsten trioxide.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Degradation on Methylene Blue

- Details

- Category: Tungsten Information

- Published on Friday, 15 January 2016 15:26

Methylene blue is phenothiazine salt, and it is unstable positive charge. It can be dissolved in water or ethanol, insolubling in ether. Methylene blue is more stable in the air; the solution is alkaline and toxic. Methylene blue is widely used in terms of chemical indicators, dyes, coloring agents and biological drugs. It can be used in the manufacture of ink and color lakes and organisms, bacteria and other aspects of the organization of chromatin. It is used to treat methaemoglobinaemia because of the reduction of methylene blue and its injection. Nitrobenzene is also used for rescue, nitrite and cyanide poisoning. Because of its role of disinfection, methylene blue can be treated with its cystitis and urethritis. In addition, methylene blue will be discharged into the body 30 minutes (injection) several hours (oral) within the urine, which resulting in urine temporarily blue, it is also used for determination of renal function. In the breeding of ornamental fish, the methylene blue solution is 0.1-0.2ppm that can be used as a disinfection treatment of white spot disease or other diseases.

Methylene blue is phenothiazine salt, and it is unstable positive charge. It can be dissolved in water or ethanol, insolubling in ether. Methylene blue is more stable in the air; the solution is alkaline and toxic. Methylene blue is widely used in terms of chemical indicators, dyes, coloring agents and biological drugs. It can be used in the manufacture of ink and color lakes and organisms, bacteria and other aspects of the organization of chromatin. It is used to treat methaemoglobinaemia because of the reduction of methylene blue and its injection. Nitrobenzene is also used for rescue, nitrite and cyanide poisoning. Because of its role of disinfection, methylene blue can be treated with its cystitis and urethritis. In addition, methylene blue will be discharged into the body 30 minutes (injection) several hours (oral) within the urine, which resulting in urine temporarily blue, it is also used for determination of renal function. In the breeding of ornamental fish, the methylene blue solution is 0.1-0.2ppm that can be used as a disinfection treatment of white spot disease or other diseases.

Tungsten trioxide is a semiconductor photocatalyst that can be used to degrade contaminants in water. In the reaction of photocatalytic treatment of methylene blue with tungsten trioxide, the optimum processing conditions for the tungsten trioxide are dosage 50mg, reaction time 40min, H2O2 dosage 4mL. We can determine the degradation reaction in different tungsten trioxide photocatalytic reaction system in the series by a kinetic study. The use of tungsten trioxide photocatalytic degradation of contaminants in water is one of the more popular research topics; the photocatalyst can generate holes and have a strong oxidizing power of hydroxyl radicals in the reaction, which helps it to get so much attention.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparation of Nanometer Yttrium Oxide Dispersion Tungsten Strengthened Alloy from Ammonium Paratungstate 1/2

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:57

The key factors that determine the properties of oxide dispersion strengthening of tungsten alloy is based on the oxide particle size and particle distribution, that is to say, the smaller size of oxide particle, the better uniform the particle distribution is, and the properties of tungsten alloy will be more superior. Certain oxides, such as La2O3, HfO2, Y2O3, because of their high melting point, good heat stability, and small solubility in tungsten, often used as tungsten dispersion strengthening phase for graining refinement and promote the densification of the material. The nano level yttrium oxide (Y2O3) with the best dispersion strengthening, can obviously refine the tungsten grains, and can achieve the goal of improving the armour-piercing and self sharpening ability of tungsten alloy. Y2O3is a white and maybe slightly yellow powder, and it is insoluble in water and alkali, but soluble in acid. It often used as magnetic and main raw materials in microwave and military, and can also be used as additive for optical glass and ceramic materials, and a big screen TV with high brightness fluorescent powder and other imaging tube coating.

Tungsten alloy commonly producing by adding yttrium oxide powder into tungsten and tungsten carbide powder, then directly make tungsten powder by ball grounding, and then press and calcined to form it. The advantage of this method is fewer steps, easy to operating, less equipment requirements, and the production is easy to achieve. However, it has the huge disadvantages like: raw materials are easy to mixing uneven. While due to the nanosize powder of Y2O3is easy to agglomerate, it results in dispersed phase and grain boundary segregation of tungsten alloy grains. A new way is proposed, which is take ammonium paratungstate (APT) as raw material and the yttrium oxide as the dispersion strengthened phase to producing nanometer yttrium oxide dispersion tungsten strengthened alloy with high density and hardness.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nanocomposites Tungsten Carbide Prepared from Ammonium Paratungstate 2/2

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:53

2. Place the carbon nanotube in ammonium paratungstate (APT) solution, adding alcohol and monohydrate citric acid at the same time, stirring. The volume of alcohol and monohydrate citric acid added is account for 1% the volume of ammonium paratungstate solution with carbon nanotube. The properties of solubility and dispersion that solutes dissolute in the mixed solution were enhanced by carbon nanotube;

3. Adjusting pH and sol formed

Adding formic acid in the mixed solution, adjusted pH to value 1~3, and heated to 70~80℃, stirring at the speed of 20~30r/min, continuous stirring for 25~35 hours until the formation of sol;

4. Drying the sol in the vacuum environment, then gel formed

Placing the sol in a vacuum environment of 110~125℃ for 8~11 hours, and then gel obtained;

5. Making gel into powder, screening, and reduction in hydrogen

Making gel into powder, then screening, sieve pore of screen is 300 mesh; reducing powder screed in hydrogen of purity more than 99.99% and flow of 50~500ml/min, temperature of 500 to 800℃, and time for 1-10 hours, and then get nanocomposites tungsten carbide.

Nanocomposites tungsten carbide produced in this method that the distribution of carbon nanotube is uniform, and the average particle diameter is 20nm~ 80nm, more over tungsten cover on the outer surface of carbon nanotube. By adjusting the three variables in the preparation process like the hydrogen flow rate and the temperature and time of the hydrogen reduction, so it can be ensured to prepare nanocomposites tungsten carbide.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nanocomposites Tungsten Carbide Prepared from Ammonium Paratungstate 1/2

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:49

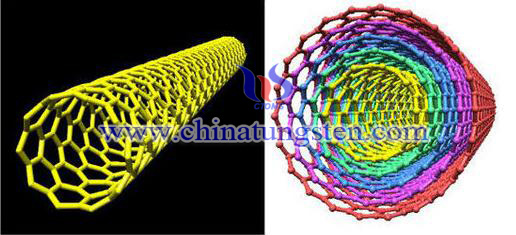

Nanocomposites material is using resin, rubber, ceramics and metal as continuous phase, and using nanometer sized metal, semiconductor, rigid particles and other inorganic particle, fiber, carbon nanotube modifier as dispersed phase, through appropriate preparation method of modified agent homogeneity of dispersion in the matrix material to form contains nanosize materials of the composite system, also known as nano materials. Carbon nanotube is a kind of ideal modified material, because the properties of high strength, elastic modulus, specific surface area, electrical conductivity, temperature stability and thermal conductivity, low thermal expansion coefficient and good resistance to acid and alkali it has. A method to prepare nanocomposites of tungsten carbide uniform dispersed carbon nanotube in tungsten to achieve mass and universal production. And the original properties of tungsten can remained and also improved.

Principle: Using the adsorption tungsten of carbon nanotube to restore nanocomposites tungsten carbide from ammonium paratungstate in the gas of hydrogen.

Steps as following:

1. Obtaining modified neutral carbon nanotube

Set carbon nanotube in concentrated nitric acid under 65-75℃, ultrasonic dispersion for 20-40min; then heated to 80 to 95℃ and reflux for 1 to 3 hours, after cooling down to room temperature, diluted in ionized water and filtered until the solution become neutral; drying the neutral particles in vacuum environment of 70-85℃ for 1.5 to 3 hours to modify the neutral carbon nanotube.

Remark: 1g carbon nanotube is obtained in 100 ml of concentrated nitric acid.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Year Of Monkey New Year Celebrating Tungsten Gold-plated Blocks

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:48

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-plated Bars Barrel Plating Production Process

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:41

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Molybdenum Sulfide Precipitation Separating Tungsten and Molybdenum from Sodium Tungstate Solution Influence

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:40

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Molybdenum Sulfide Precipitation Separating Tungsten and Molybdenum from Sodium Tungstate Solution

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:37

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com