GFAAS Determinate Lead Element in Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 16:56

Graphite furnace atomic absorption spectrometry (GFAAS) is the current method of atomic absorption analysis performed atomization by using a graphite material tube, cup-shaped atomizer. All participated samples in atomic avoiding dilution atomic concentration of gas in the flame, the analytical sensitivity is significantly improved. The method for the determination of trace metals is a better performance than other methods, and it can be used to analyze solid samples and the direct analysis of a small sample, so it is widely used. GFAAS is used in the field of food, medicine, environmental monitoring, health, and other aspects of clinical medicine.

Lead is weak and strong, poisonous, heavy metal. The original color of it is green white in air .its surface is quickly covered with a layer in dark gray oxide. It can be used for construction, lead-acid rechargeable batteries, warheads, artillery shells, welding materials, fishing equipment,, radiation protection materials, trophies and part of the alloy, such as pewter electronic welding used. Lead is a metal element; it can be used as sulfuric acid, corrosion-resistant, anti-gamma ray, batteries and other materials. Type alloys of lead can be used as bearings, cable sheathing and other purposes, but also sports equipment shot.

Weighing 0.5g of tungsten trioxide in a quartz beaker, adding 10ml of ammonia dissolved in the low temperature furnace, adding 10ml 10% tartaric acid after cooling, and shaking the quartz agent, diluting to the mark with distilled water. Experimental results show that using tartaric acid complex tungsten can eliminate entrainment effect of lead tungstate in the mixed solution. Due to the high chloride and lead form gaseous metal chloride, chlorine moiety with the purge gas discharge caused by the loss of the lead, so the impact on the determination of nitrate increases.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Slime Processing in Wolframite Dressing

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 16:56

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-plated Coins And Gold Coins Differences

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 16:46

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-plated Coins For Real Estate gifts

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 16:43

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Polymers Main Properties

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 16:00

The main properties of tungsten polymer are mainly as follows:

High density of 11.0 g/cc

Enhancing radiation shielding performance

Improve flexibility properties

Easily malleable

Non-toxic

Resistance to corrosion by weather elements

Resistant to corrosion by chemical and organic solvent resistance

Insoluble in water

No harmful effects when handling or processing

With the above main properties, tungsten polymer has found many applications in fields and industries, including:

X-ray devices in manufacturing industries and medical X-ray machines

Nuclear and medical industries for radiation shielding

Used in weight and balance applications as a counterweight for applications like motors, ballasts, and more.

Used as a sound proofing material in aviation headphones

Acts as a damper to reduce shock due to vibration in the automotive industry

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Polymers: The Best Replacement To Lead

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 15:17

Lead is a heavy metal and can be poisoning the day to day operations of human organs are inhibited. Despite these health risks, lead is very useful in industries today because of the properties it possesses, such as its malleability and low melting point making it easy to mold and melt, in addition to its low cost which makes it economical for use for industrial purposes.

Recent studies show that the heavy usage and poor disposal of lead products for decades has caused irreversible effects to the environment and as such lead is now ranked as the second most hazardous substance by the United States government. A kind of material without toxic needed badly, tungsten polymers are being introduced as an effective lead alternative in a variety of applications for which lead has traditionally been used. This push for alternatives is due to the threat that leads poses to the environment and to human health.

Therefore, tungsten polymers have become a notable alternative to lead in numerous applications because they can match the physical properties of lead, like high density, while being environmentally benign. This polymer composite is made up of tungsten powder and a plastic base resin, which are compounded together into a thermoplastic material at 11 g/cc, the same density as lead. The base resin systems are made up of; polysulfones (PSU), co-polymides, polyamides (PA), polymethylpentenes (PMP), polyurethanes (TPU), acryloynitrile butadiene styrene (ABS), polyethylenes (PE) and polyetheretherketones (PEEK).

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

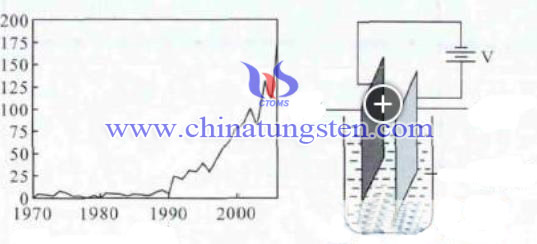

Electrophoretic Deposition Tungsten Trioxide Thin Film

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 13:49

WO3 thin film renders color by irradiation with light or by using an appropriate electric field energy that referred to as a photochromic or electrochromic, which has potential applications in smart windows, large area displays and automotive mirrors, etc. Preparations of WO3 thin films are electrophoretic deposition magnetron sputtering, chemical vapor deposition, and sol - gel method.

Electrophoretic deposition refers to a stable suspension by the action of the electric field, the colloidal particles deposited material called electrophoretic deposition process. E.g., DC voltage is applied to the electrodeposition coating, and charged paint particles move to the cathode, and the cathode surface with an alkaline effect is produced by the formation of insoluble material deposited on the work surface. There are two processes on accordingly electrophoretic deposition comprises, one is electrophoresis, and the second is deposition. Entire electrophoretic deposition process is divided into the following four steps:

Electrophoretic deposition refers to a stable suspension by the action of the electric field, the colloidal particles deposited material called electrophoretic deposition process. E.g., DC voltage is applied to the electrodeposition coating, and charged paint particles move to the cathode, and the cathode surface with an alkaline effect is produced by the formation of insoluble material deposited on the work surface. There are two processes on accordingly electrophoretic deposition comprises, one is electrophoresis, and the second is deposition. Entire electrophoretic deposition process is divided into the following four steps:

(1) Electrolytic: initially, producing hydrogen and hydroxyl ions OH is the reaction at the cathode electrolysis reaction, the reaction resulting in the formation of an overbased cathode surface boundary is layer, when the effect of the cation and the hydroxide becomes water-insoluble substances, it coating film deposition:

(2) Electrophoresis: the cationic resin and H + in the electric field moves to the cathode, and anions to the anode movement;

(3) Electrodeposition: the surface to be coated, a cationic resin and the surface of the cathode basic acting, and not precipitated sediment deposited on the workpiece.

(4)Electro-osmosis: thin film coating on the surface of the solid and translucency with the majority of the pores leaking water that is discharged from the cathode coating thin film in the electric field, which causing the coating dehydration. Tu film is adsorbed on the surface, completing the electrophoresis process.

Dissolving amount of tungsten powder with hydrogen peroxide (H2O2), to prevent bumping solution, H2O2 should be added and dissolved during stirring constantly. After cooling and filtering completely, adding the appropriate amount of concentrated sulfuric acid (CH3CH2OH) and acetic acid in the filter solution (CH3COOH), which can get WO3 sol. Electrophoretic deposition is conducted under greenhouse, and the current density is DC steady flow instrument, preparing WO3 thin films from taking the substrate as an electrode, the current passing through the cathode that can be deposited WO3 thin film, which can obtaining the deposition required thickness, simple operation, a film-forming, high transparency, film uniformity and the substrate with a solid advantage.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium Tungstate, Sodium Molybdate and Other Reagents Synergistic Corrosion Inhibition

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 19:44

When adding sodium molybdate and sodium tungstate alone in the simulated cooling water, with the increase of the concentration of sodium tungstate and sodium molybdate in simulation cooling water, the corrosion rate of carbon steel gradually reduces and the corrosion rate increases. But to achieve better corrosion inhibition effect, the concentration of sodium molybdate and sodium tungstate is required quite high. In order to reduce the amount of sodium molybdate and sodium tungstate, this paper introduces the synergistic corrosion inhibition of sodium molybdate, sodium tungstate and common organic phosphoric acid (HEDP), orthophosphoric acid and Zn2+.

When adding sodium molybdate and sodium tungstate alone in the simulated cooling water, with the increase of the concentration of sodium tungstate and sodium molybdate in simulation cooling water, the corrosion rate of carbon steel gradually reduces and the corrosion rate increases. But to achieve better corrosion inhibition effect, the concentration of sodium molybdate and sodium tungstate is required quite high. In order to reduce the amount of sodium molybdate and sodium tungstate, this paper introduces the synergistic corrosion inhibition of sodium molybdate, sodium tungstate and common organic phosphoric acid (HEDP), orthophosphoric acid and Zn2+.| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium Molybdate and Sodium Tungstate Corrosion Inhibition to Carbon Steel

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 19:41

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium Molybdate and Sodium Tungstate Corrosion Inhibition to Stainless Steel

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 19:39

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com