New Ion Exchange Process in High Concentration Sodium Tungstate

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 19:35

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Testing Molybdenum Content in Sodium Tungstate Solution

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 19:33

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ion Exchange Method Separating Vanadium in Sodium Tungstate Solution

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 19:29

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Controlling Content of Sodium in Ammonium Paratungstate 1/3

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 18:18

In the tungsten metallurgy industry, ammonium paratungstate (APT) is an important intermediate, and the degree of purity of APT will affect the quality of tungsten products. The content of sodium can affect the particle size of tungsten powder. The APT with high sodium can be used to prepare coarse grain tungsten powder and APT with low sodium can be used to prepare thin tungsten powder. Tungsten powder is the main material for tungsten carbide, and the particle size of tungsten powder plays a key role in tungsten alloy properties. The properties of the alloy with fine grain tungsten powder are significantly higher than that of the tungsten powder with coarse grain. If tungsten powder particles are ultrafine particles, then properties of tungsten alloy will have a qualitative leap, to achieve the goal of high strength and hardness, thus expanding the application field.

In industry, in order to obtain fine particles of tungsten powder, reduce the content of sodium in APT is an effective way. Seven aspects such as rate of APT crystal, crystallization temperature and time and so on are analyzed to help reducing content of sodium in APT.

1. APT crystallization rate

In the initial stage of APT crystallization, due to the over saturation of APT, both crystal-nucleation and crystal growth rate are very fast, small particles of APT are produced, at this time, sodium get inside crystal easily. Super-saturation of solution decreased rapidly with crystallization continue, the fine APT crystals with high content of sodium and surface dissolved easily, but the large crystals with less sodium continue growing, making sodium in APT decreased. And with the mother liquor concentrate, the concentration of Na+ increased, that making the contact area of apt and Na+ increased, sodium in APT rising again.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Behavior of Tin in Producing Ammonium Paratungstate 2/3

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 18:02

Tin compound is of amphiprotic, it exists in water, acid and alkali in the form of +4 valence and +2 valence compounds, ionic radii were 0.71*10-10m and 1.2*10-10m. Adding moderate amount of NaOH into the solution containing Sn2+ precipitated white Sn(OH)2. Sn(OH)2 can not only dissolve in acid to generate Sn2+, but also dissolve in excess of NaOH solution to generate [Sn(OH)3]-、[Sn(OH)4]2-. At the same time, add alkali in the solution containing Sn4+ ions can generate the alpha tin acid gel (H2SnO3) which is difficult to dissolve in water. H2SnO3 react with acid to generate Sn4+, but also can react with alkali to get SnO32-. In addition, tin has another important compound—tin sulfide with two forms SnS and SnS2, SnS2 will decompose and get SnS when heated to 520℃. Both SnS and SnS2 can not soluble in water and dilute acid, but can react with high concentration of HCl. SnS is not soluble in alkali in the low oxygen state, however SnS2 can produce sulfostannate and stannate in alkali. In APT production process, the solution is sometimes acidic, and sometimes alkaline, and the strength of the acid and alkali is different, which makes the varieties forms of tin.

In the general alkali decomposition conditions, choose concentration of 500g/L NaOH solution, 1.6 times as much as that of the theoretical amount to ensure reaction in the alkali excessive state, reaction time of 4 h, setting temperature in three value of 150℃, 160℃, 170℃, and selecting two different types of minerals to observe under different temperature. The effect of reaction temperature on the leaching rate of tin is shown below:

From the above, we can draw that leaching rate increased with reaction temperature increasing, and the increasing speed is far greater than leaching rate of tungsten. That means compared to tungsten leaching reaction, tin leaching reaction shows more tendency to thermodynamic control.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-plated Chopsticks For Wedding Gifts

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:47

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gold And Tungsten Gold-plated Products Maintenance Precautions

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:44

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Air Curtain Counterweights

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:42

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Effect of Powder Property on Tungsten Copper Electrode Density (1 of 2)

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:00

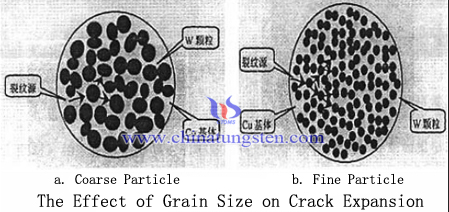

Too fine granularity of tungsten powder has bad heat shock resistance, it is easily to produce cracks when arcing, which decreases the hardness and the density of contacts and increases the resistivity. In addition, in the electric arc, the gap at the easy to crack, copper-rich copper areas prone ablation spatter, even vaporization, forming a contact surface cavities, pits and cracks and other defects. Too coarse tungsten powder, on the one hand will decrease the contact area of tungsten powder particles, in the process of sintering tungsten framework between tungsten powder particles can not form a good bond necking, it is difficult to form a high strength tungsten skeleton. This further influenced the subsequent sintering process combined with weaker intensity tungsten framework by liquid copper erosion leaving the bonding strength further reduced, resulting in decreased tungsten copper W-Cu electrode contact material hardness.

Tungsten powder granularity has a great influence on hindering the cracks expanding. Smaller particle size tungsten powder, tungsten particles dispersed after sintering. When the micro crack copper matrix and tungsten particles, tungsten particles will encounter more, every encounter, micro crack bifurcation occurs, thereby increasing the crack propagation energy consumption. Thus, the dispersed tungsten powder can be more effectively suppressed crack propagation, the tungsten copper electrode material bonding strength has been significantly improved. On the other hand, tungsten powder particle size is too coarse, the tungsten skeleton pore becomes large, easy to cause evaporation under arcing splashing copper electrode degree of burning increases, leading to a galvanic corrosion rate is increased. It is a good way to get tungsten copper electrode material with excellent properties that use different granularity of tungsten powder matched.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

New Types and Structure of Coated Cemented Carbide——Diamond Coating (1 of 3)

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 16:57

As we know, diamond is the hardest material in the world so far. It has high density (3470-3560kg/m3), high hardness (Mohs’ scale of hardness is 10), high melting point (3550℃-4000℃). Although diamond has stable chemical property and excellent wear resistance, it is difficult to manufacture the required parts or products directly. Therefore, diamond coating by CVD (Chemical Vapor Deposition) can effectively solve the problem, which is widely used in the mould of metal wire processing. Diamond coating deposits a layer of polycrystalline diamond film on tungsten carbide matrix mainly by low pressure chemical vapor deposition (LPCVD), it can remarkably improve the hardness and wear resistance of tungsten carbide.

Take the consumables of metal wire as an example, drawing die mainly includes two kinds that tungsten carbide mould and polycrystalline diamond mould in the wire industry, while the quality, the efficiency and the comprehensive properties of metal wire is greatly determined by the properties of drawing die. Tungsten carbide mould has good hardness and toughness, the production cost is lower than polycrystalline diamond, but it is easily adhered by compounds so that its service life is shorter than polycrystalline diamond; polycrystalline diamond has excellent hardness and wear resistance, and it has higher mould cost, it is difficult to manufacture the larger size and abnormal mould, which has lower plasticity and toughness. Diamond coated cemented carbide mould by LPCVD not only combines with both advantages of diamond and tungsten carbide, but also overcomes the defects of them, which is one kind of the most widely used new drawing die. The sketch of drawing die working as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com