Platinum-Doped Tungsten Trioxide Effect on Methanol

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 18:15

Platinum (Pt) is a shiny silver-white metal, its melting point is 1772 ℃, and the boiling point of 3827 ± 100 ℃, the density is 21.45 g / cm 3 (20 ℃), it is relatively soft. Platinum is full of good ductility, thermal and electrical conductivity. Platinum reference material (such as platinum sponge), a large surface area for gas (especially hydrogen, oxygen and carbon monoxide) have strong absorption capacity. Platinum due to its high chemical stability and catalytic activity, commonly used in the chemical industry as a catalyst, such as platinum hydrogenation, dehydrogenation, isomerization, cyclization, dehydration, dehalogenation, oxidation, pyrolysis and other chemical reactions .

Platinum (Pt) is a shiny silver-white metal, its melting point is 1772 ℃, and the boiling point of 3827 ± 100 ℃, the density is 21.45 g / cm 3 (20 ℃), it is relatively soft. Platinum is full of good ductility, thermal and electrical conductivity. Platinum reference material (such as platinum sponge), a large surface area for gas (especially hydrogen, oxygen and carbon monoxide) have strong absorption capacity. Platinum due to its high chemical stability and catalytic activity, commonly used in the chemical industry as a catalyst, such as platinum hydrogenation, dehydrogenation, isomerization, cyclization, dehydration, dehalogenation, oxidation, pyrolysis and other chemical reactions .

The architecture of Methanol (CH₄O) is the most simple saturated alcohols , its molecular is 32.04, the boiling point is 64.7 ℃. It is called as "wood alcohol" because it is discovered in carbonized Methanol with alcohol is colorless volatile liquid. Methanol is used as organic extractant and alcohol denaturation agent in the manufacture of formaldehyde and pesticides.

The preparing of hollow branch structure of tungsten trioxide vector (d-WO3) is made from hydrothermal method and sacrifice templates. A further load on its surface is active ingredient Pt; we can obtain nanometer Pt / d-WO3 composite catalyst. X-ray powder diffraction (XRD), transmission electron microscopy (TEM) and specific surface area and pore structure analysis (BET), etc. The morphology and structure of the catalysts were characterized. The results show that the tungsten trioxide having a length and a width of 6μm 2μm hollow dendritic structure of pore, and the size of distribution mainly is in 20 ~ 120 nm, a specific surface area of 24 m2 / g, an average particle diameter of 7.2 nm. The nanoparticles uniformly distributes thereon surface. The study of the Pt / dWO3 catalyst in the acidic solution electro-catalytic oxidation of methanol is used by cyclic voltammetry and chronoamperometry. The results shows, Pt / d- WO3 catalyst ratio Pt / C and Pt / WO3 catalyst for methanol have a higher electro-catalytic oxidation activity and stability. Hollow mesoporous structure has the d-WO3 and bifunctional mechanism of action in favor of direct dehydrogenation of methanol oxidation process at the platinum surface.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Disposing Hydrogen Chloride in Ammonium Paratungstate Production

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 18:14

In the process of producing ammonium paratungstate, the classical method to decompose the sodium tungstate is using hydrochloric acid (HCl). Hydrochloric acid coming from HCl gas dissolved in water, a strong acid with prosperities of transparent (the high concentration of hydrochloric acid presents yellow), irritating odor and strong corrosion. Hydrochloric acid is highly volatile, when concentration of HCl in the water more than 20.22%, a small quantity of water containing hydrogen chloride volatile; when concentration of HCl in the water more than 37%, HCl gas volatiles. HCl gas will quickly combine with water vapor in the air which is called the white mist. In the industrial APT production, a large number of hydrogen chloride gas volatile and went into atmosphere, forming acid rain which is causing serious harm to humans, animals, plants, buildings and so on. For the requirements of environmental protection and recycling, we need to deal with HCl waste gas.

Acid decomposition is an exothermic process, in the production of APT, a large number of heat released with the continuous reaction, then HCl gas will continue to volatile with the raising temperature. Disposing hydrogen chloride need to consider the economic, social, environmental benefits, analyze with the following three methods.

1. Cleaning process

Consider to change the production process, use the minimum input to adjust the process route, in order to avoid the production of HCl. For the traditional preparation of APT process, the production of HCl gas is inevitable, because hydrochloric acid is a main material. However, we can control reaction speed and reaction temperature, and then achieve the purpose of reducing the amount of HCl volatilization;

2. Acid-base neutralization

HCl is an acid gas. The simple, Acid-base neutralization is the direct and effective way to dealing. A large number of low concentration alkaline waste water is discharged in tungsten alkali decomposition process; so we can use them for washing HCl gas to eliminate HCl waste gas.

3. Solidification

MH3 and HCl are both generated in the APT production, and these two gases are very easy to produce solid ammonium chloride, also achieve the goal of disposing hydrogen chloride.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Titanium Oxide-Tungsten Trioxide Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 18:05

Nowadays, it is universal for organic pollutants in the atmosphere or water, and the semiconductor TiO2 has catalysis and degradation of organic pollutants in the atmosphere or water, it is non-toxic, safe, cheap, abundant, etc., which leads its widely application. However, as a wide band gap semiconductor, TiO2 can only absorb sunlight accounts from 3% to 5% in the UV light, and thus a lower photocatalytic efficiency; what is more, since the photo-generated holes - electrons pair ,the quantum efficiency of TiO2 is very low. How can achieve the degradation of organic pollutants in water under visible light conditions?

Nowadays, it is universal for organic pollutants in the atmosphere or water, and the semiconductor TiO2 has catalysis and degradation of organic pollutants in the atmosphere or water, it is non-toxic, safe, cheap, abundant, etc., which leads its widely application. However, as a wide band gap semiconductor, TiO2 can only absorb sunlight accounts from 3% to 5% in the UV light, and thus a lower photocatalytic efficiency; what is more, since the photo-generated holes - electrons pair ,the quantum efficiency of TiO2 is very low. How can achieve the degradation of organic pollutants in water under visible light conditions?

To overcome these two shortcomings, we prepare a large specific surface area and high catalytic activity of TiO2 UV nanorods (TiO2-NRs)by taking the nanometer TiO2 as a precursor and by hydrothermal calcination; preparing calcined TiO2-NRs as the carrier at 400 ℃, using a sol - gel method when WO3 / TiO2-NRs composite photocatalyst, the results show WO3 loading of 2%, WO3 / TiO2-NRs photocatalytic activity under the same light conditions is 5 times of P25. The WO3-TiO2 samples were used rhodamine – dichloroph enoxyacetic acid decolorizing, the reaction solution was found to have a high-speed decolorization properties in solution.

Experiment Conclusion:

1. Mesoporous WO3 / TiO2 composites prepared by adoption of calcinations hydrothermal and sol - gel Preparation.

2. Tungsten trioxide titanium composites exhibit two-dimensional hexagonal symmetry p6mm pore structure and having anatase crystalline structure.

3. Titanium tungsten trioxide complex is narrower than pure titanium dioxide narrower bandgap.

4. Photocatalytic Performance 4.WO3 / TiO2 composites by a xenon light source (λ400 nm) irradiation to degrade organic pollutants in water, compared with pure TiO2, the photocatalytic activity of composite materials has been significantly improved.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide-Graphene Catalytic Activity Exploration

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:50

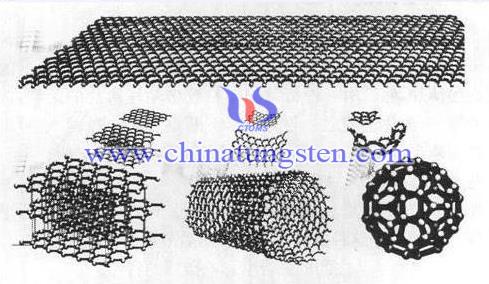

Graphene is stripped out from graphite material, composed of carbon atoms, carrying with one atom thick two-dimensional crystals. Graphene is not only the thinnest material but also the most robust materials; the fracture strength of it is even higher than the best steel 200 times. It has good flexibility, tensile amplitude and can reach 20% of its own size. It is the nature of the thinnest, highest material strength. On the other hand, it is very compact, even the smallest gas atom (helium atoms) can not penetrate. These features enable its application in various fields.

Catalytic activity refers to the ability of the catalytic substance; it is one of the important properties of the catalyst. There is a surface phenomenon because the size of the catalytic activity and the specific surface area of the solid, the nature and unit surface area on the surface of the active center of the active center of the quantity. To describe the differences in the catalytic activity of different substances, we can call the catalyst per unit surface area per unit time, which shows the amount of raw materials can be converted into a specific activity; the number of molecules in each of the active center in one second is called the turnover number of conversion or digital conversion.

Catalytic activity refers to the ability of the catalytic substance; it is one of the important properties of the catalyst. There is a surface phenomenon because the size of the catalytic activity and the specific surface area of the solid, the nature and unit surface area on the surface of the active center of the active center of the quantity. To describe the differences in the catalytic activity of different substances, we can call the catalyst per unit surface area per unit time, which shows the amount of raw materials can be converted into a specific activity; the number of molecules in each of the active center in one second is called the turnover number of conversion or digital conversion.

The catalyst synthetic material of visible graphene tungsten trioxide (m-WO3 @ RGO) is prepared from Photoreduction(the reduction reaction of organic compound in light of the role) Under visible light conditions (λ420nm), photocatalytic m-WO3 @ RGO composites with 0.5wt% Pt , which leads oxygen speeds up the decomposition of aquatic 21.26μmolh-1.

The Combination of ordered mesoporous tungsten trioxide and two-dimensional structure of graphene can improve the transfernation of photogenerated electron activity of m-WO3 @ RGO composites. This study effectively expands the graphene-based materials in the field of energy conversion applications. The discovery of graphene is the thinnest, highest intensity, the strongest thermal conductivity properties of a new type of nano-materials. The added -graphene metal well disperse in the substrate material, inhibiting their reunion because it has a higher ratio surface area, higher reactivity and selectivity.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-plated Commemorative Coins For Bank Credit Card Integral Redeem

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:46

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What Is Soft Tungsten Gold?

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:44

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Difference Between 18K Tungsten Gold-plated And 18K Gold

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:42

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Coated Cemented Carbide Types——Gradient Coating (2 of 2)

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:12

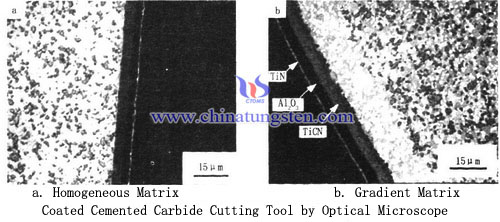

It is necessary to compare with gradient tungsten carbide. Gradient coating refers to gradient arrangement in coating structure, while coated cemented carbide is not only determined by the coating material, the more closely related to the properties of tungsten carbide matrix. Tungsten carbide matrix with gradient structure effectively solves the problem that the cracks of coating layer extend to tungsten carbide matrix. It adds a spot of TiN, (Ti,W)C and some phase with cubic structure in WC-Co system, and adopts nitrogen removal process to form no cubic phase and Co binder phase concentration with gradient structure, which has excellent toughness and in case of the cracks expanding to some extent. There is homogeneous tungsten carbide matrix and tungsten carbide with gradient structure pictures under optical microscope as follow:

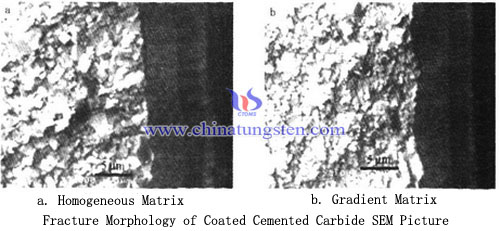

It is distinct that there is a big difference between homogeneous tungsten carbide matrix and gradient structural tungsten carbide matrix. In addition, compared with the fracture morphology of coated cemented carbide cutting tool SEM (Scanning Electron Microscope) picture:

Viewed from the fracture morphology of coated cemented carbide SEM picture, we can find that the fracture morphology of tungsten carbide cutting tool with gradient structure is coarser and unevener than homogeneous tungsten carbide cutting tool. Due to high toughness of Co concentration, it can absorb almost energy of cracks expanding, which increases the plastic deformation. It proves that tungsten carbide with gradient structure has better impact resistance toughness and cutting edge toughness.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Coated Cemented Carbide Types——Gradient Coating (1 of 2)

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:09

Since coated cemented carbide developed, coating types were diverse, such as single-layer coating, multi-element composite coating, gradient coating, nano coating, super-hard coating and soft coating.

3. Gradient Coating

Due to the differences of friction factor and coefficient of thermal expansion between coating layer and the matrix, if it can not be effectively controlled, the binding force of coated cemented carbide will remarkably decrease. Gradient coating solves the problem perfectly, which has structural composition and micro-structure in the space. It can reduce the concentration of the stress, eliminate the surface of multi-layer, which improves the binding strength of coating layer and matrix, and extends the service life of coated cemented carbide.

It can be found that gradient coating has better micro-hardness and toughness by analyzing the section structure and composition distribution of gradient Ti(C,N) coating layer. The related researcher adopted magnetron sputtering to deposit gradient TiAlN coating on tungsten carbide matrix, and injected Ti atom between the gradient coating and the matrix by metal vapor vacuum arc (MEVVA), which formed a transition layer with a certain concentration of Ti. After that this kind of tungsten carbide with gradient coating performed perfectly in the test of dynamic impact, and has better wear resistance and toughness in high-speed cutting or milling and been a giant leap in the service life.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

China Tungsten Resource Characteristics

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 11:53

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com