How to Drill Glass With Carbide Tool

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 15:14

Place a piece of masking tape onto the surface of the glass where you want to carbide drill your hole. Mark onto the tape the location of the hole.

Load the desired size carbide carbide drill bit into your carbide drill, set the speed to slow and the rotation of the carbide drill forward (clockwise). Don your safety glasses.

Start carbide drilling the hole. At slow speed, place the tip of the bit on your marked hole and begin carbide drilling very slowly. Think of this as grinding down the glass rather than cutting a hole through it, as glass is very brittle it must be ground down. Do not push the carbide drill against the glass; let the bit do the work slowly and gently.

Cool the glass as you go. Have a friend pour a stream of water over the site of the hole while you are carbide drilling. The friction created by the carbide drill bit will create a lot of heat, which can damage the bit or crack the glass. Use a garden hose if possible to supply a constant stream of water during carbide drilling. Stop the carbide drill once the hole has been made.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

WC-Co Carbide Bits Failure in Coalfield Application

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 15:11

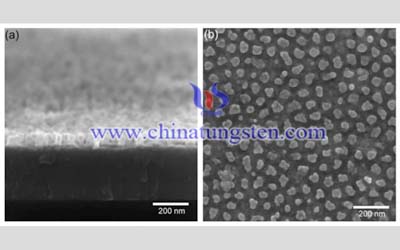

WC-Co cemented carbides bits has unique combination of hardness and toughness makes it especially suitable for wear resistant parts of tools for rock drilling. When the failures of WC-Co cemented carbides bits of cutters used in coalfield were analysed carefully by scanning electron microscopy, it was suggested that bending rupture, abrasion and cracking were the main types of failure of WC-Co bits.

Based on the fractography, it is indicated that the causes of the failures of the bits are impact load stress which may reach or even exceed the transverse rupture strength of WC-Co alloys, abrasive wear, surface impact fatigue and thermal fatigue. In accordance with these causes, some methods like adjustment of alloy composition, changing particle size to enhance the properties of the alloy are suggested to prolong the lifetime of cutters.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Tungsten Alloy be Used in Calorimeters

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 18:52

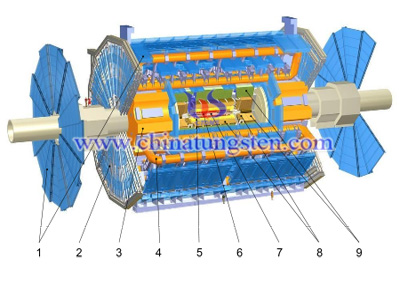

The calorimeters are one component of radiation detector, and situated outside the solenoidal magnet that surrounds the Inner Detector. Their purpose is to measure the energy from particles by absorbing it. There are two basic calorimeter systems: an inner electromagnetic calorimeter and an outer hadronic calorimeter.Both are sampling calorimeters; that is, they absorb energy in high-density metal like tungsten alloy.

The electromagnetic (EM) calorimeter absorbs energy from particles that interact electromagnetically, which include charged particles and photons. Tungsten alloy for calorimeters has high precision, both in the amount of energy absorbed and in the precise location of the energy deposited.The barrel EM calorimeter has accordion shaped electrodes and the energy-absorbing materials can be tungsten alloy, with liquid argon as the sampling material.

The hadron calorimeter absorbs energy from particles that pass through the EM calorimeter, but do interact via the strong force; these particles are primarily hadrons. The energy-absorbing material is tungsten alloy, with scintillating tiles that sample the energy deposited.It is better to choose tungsten alloy for calorimeter to guarantee cost-effectiveness. According to the photograph below, tungsten alloy for calorimeter is in the part of 9.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Tungsten Alloy for Radiation Detector

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 18:43

A radiation detector, also known as a particle detector, is a device used to detect, track, and/or identify high-energy particles, such as those produced by nuclear decay, cosmic radiation, or reactions in a particle accelerator. Modern detectors are also used as calorimeters to measure the energy of the detected radiation. They may also be used to measure other attributes such as momentum, spin, charge etc. of the particles.

When using tungsten alloy to produce radiation detector,particles through some tungsten alloy, tungsten alloy will absorbing part of particles or all of them to produce ionization or excitation. Radiation detectors transfer ionization or excitation into all forms of direct or indirect information that human can accept.

The advantages of tungsten alloy for radiation detector:

Due tungsten alloys have the ability of various high-ray shielding,tungsten alloy can be the good materials for radiation detector. The thickness 3mm of tungsten alloy can shield 95% of 150keV γ radiation. Tungsten alloy materials are suit for high spatial resolution occasion, such as radiological Imaging array detectors.Tungsten alloy materials has high density, (60% higher than lead), reduces the size of tungsten alloy ray shields, without affecting the radiation shielding effect.Comparing with tungsten alloy and lead, when they with the same performance of radiation shielding, the volume of tungsten alloy is 1/3 of lead .Because the environmental friendly characteristics of tungsten alloy, tungsten alloy for radiation detector better than lead for radiation detector in environmental protection .In the future, tungsten alloy for radiation detector will be wildly used.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Working Principle of Radiation Detector

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 18:41

Radiation detector is a device or material used to observe and study for radiation and the microscopic phenomena of particle sensors , devices or materials.

Radiation detector works based on the interaction of particles with substance.When particles through some kind of substance, the substance will absorb part of particles or all of them to produce ionization or excitation. If the particles are electrical, its electromagnetic field track directly interact with the atoms in the material.If it is gamma rays or x-rays, the rays should go through some intermediate process, resulting in the photoelectric effect, Compton effect or electronic. Nowadays, tungsten alloy for radiation detector be wildly used in radiation detectors,since the good performance of tungsten alloy material in radiation shielding and environmental protection. Tungsten alloy for radiation detector can absorb most part even all part of particles and be environmental protection.Orbital electron energy passes on part or all of the material like tungsten alloy, and then produce ionization or excitation.

For the without electrically particles such as neutrons, it is through nuclear reactions to produce charged particles cause ionization or excitation.Radiation detectors are equipments to probe interaction of particles. The particles produce ionization or excitation in the detection medium. Radiation detectors transfer ionization or excitation into all forms of direct or indirect information that human can accept.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Titanium and Hafnium Coating Tool

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 13:42

Carbide titanium and hafnium coating tool is making titanium or hafnium metal diffused into the surface of a tungsten carbide tool instead of titanium oxide. The results are substantial improvement, both in terms of wear resistance and the surface appearance of workpieces cut with said tools, both initially and after substantial use.

The overall process for making tungsten carbide tools comprises applying a coating of titanium and hafnium metal of the Periodic Chart of the Elements over the tool, diffusing the metal into the tool and removing excess of the metal from the surface of the tool, either by further diffusion of thees metal into the tool or by removal processes such as dissolving in a suitable solvent. Tools formed in accordance with process have wear properties such that they typically last at least four times, frequently in excess of six times as long as untreated tools and with tools formed in accordance with the most preferred embodiments of the invention, nine times as long as untreated tools. Tools with those metal coating last at least three times as long as tools which have been given an oxide diffusion treatment. The surface of workpieces cut with tools treated in accordance with this invention, are substantially better than those surfaces formed using untreated tools or tools given an oxide diffusion treatment. This improvement is both with initial use of the tool as well as after a substantial cutting time.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Titanium Oxide Layers (1)

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 13:39

Carbide tool with titanium oxide layer is deliberately attempted to diffuse a titanium oxide layer into a carbide tool by applying a paste of titanium oxide over the surface of the tool and heating the tool to an elevated temperature to thereby diffuse the titanium oxide into the surface.

With regard to the above described oxide layers, though they are identifiable, the stability of these layers under the shear stresses encountered during normal cutting operations was not considered until recently. Thus, it is conceivable that the oxide layer may not be able to withstand the high shearing stresses encountered in metal cutting for a prolonged period of time and that the rate of oxide formation at the metal to metal contact may not be rapid enough to provide a continuous oxide layer. It was then considered possible that what really effected the metal cutting property was not necessarily the oxide layer alone, but the substrate layer of the carbide effected by mass diffusion of the oxide layer into the carbide tool.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Woodcutting Tools Advantages

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 13:37

Carbide woodcutting tools tipped with carbide have distinct advantages over standard woodworking tools.

Carbide remains sharper longer than plain steel, which makes makes a carbide cutting tool more efficient. Carbide enables blades to cut faster without binding, which reduces load on woodworking machines. Normal-steel cutting tools dull fast. When blades get dull, they burn the wood, cause chipping, shatter the grain and cause grain blow-out. Sharp, carbide-tipped tools are far more efficient, cutting faster and needing sharpening less often than common steel blades.

Cleaner

Carbide woodworking tools make the cleanest, straightest cuts of any of the woodworking tools, and cause little or no grain damage. When cuts are clean and straight, woodworking joints fit better and glue bonds are tighter. A carbide tool's clean cut reduces the incidence of kickback, a major cause of woodworking accidents.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Titanium Oxide Layers

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 12:01

In recent years, it has been suggested that improved tool life of tungsten carbide tools containing titanium carbide was caused by the formation of titanium oxide layers, and in some cases sulfide layers and other oxides, on the surface of the tool. This belief was based upon the showing by electron microscopy that a protective and adherent layer of Ti2 O3 was present as an intermediate layer between a TiC-TiO solid solution on the surface of the carbide tool after cutting.

It has been more recently shown that by application of cutting fluids, sulfide and oxide layers are formed in the contact zone of a carbide cutting tool and an aluminum-deoxidized steel, in which case the sulfide and oxide layers are less than 10 μm thick. It has been asserted in the prior art that the oxide layer formed on the surface of the tungsten carbide tool raises the welding temperature between the carbide tool and steel by several hundred degrees, thereby decreasing wear by the "adhesion-and-shear" process. In addition, it has also been asserted that TiO is very adherent to the carbide surface of the tool since the sub-surface forms a solid solution of TiO and TiC. Thus, it was believed that the role of the surface layer was that of reducing the frictional coefficients and preventing diffusion and the like between the tool and the workpiece.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Woodcutting Tools Advantages (1)

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 11:59

Carbide woodcutting tools’ advantages include tougher and longevity.

Tougher

Some hardwoods contain small particles of silica or minerals that can dull normal steel. Particleboard and other composite wood products may contain sand, small rocks or other kinds of debris in their cores that can damage or even ruin a common steel blade instantly. carbide woodworking tools are tough enough to cut through most debris without causing any damage to the blade or its tip. Bullets, nails and screws are commonly found inside rough, re-purposed lumber. If you hit one of these things with a normal blade, it's finished. A carbide-tipped tool may cut through them and you won't even notice.

Longevity

Carbide tips can be replaced when they wear out or break, and most tool-sharpening shops can weld new tips onto a wood working tool. The initial cost of a carbide-tipped tool is more, but the tips are replaceable, making the tool more affordable in the long run. Carbide-tipped tools last almost indefinitely if the blade body or router-bit shaft remains in good shape. It's not uncommon for carbide-tipped woodworking tools to last 20 years or more if they are taken care of and the tips are replaced regularly.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com