Tungsten Alloy in Alpha Magnetic Spectrometer

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 18:22

The Alpha Magnetic Spectrometer (AMS-02) is a large experiment in the International Space Station (ISS) intended to measure primary cosmic ray spectra in space. It sits outside of the station, looking out into space. High-energy particles pass through it, interacting with different detectors on the way.

AMS-02 Transition Radiation Detector (TRD) consists of 20 layers of straw proportional tubes alternating with layer of fiber fleece radiator. The layers are mounted in a stable and light carbon fiber composite honeycomb octagonal support, fixed by an M-structure to the AMS-02 magnet flange. The entire TRD is composed by 328 modules, ranging in length from 1.5 meters up to 2.2, for a total of 5248 straw tungsten alloy tubes. The tube wall is composed of a 72 μm tungsten alloy thick foil and the tungsten alloy sense wires are 30 μm . The tungsten alloy wires are held by the polycarbonate end pieces crimped in Copper-Tellurium blocks.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Collimator in Industrial Radiography

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 18:18

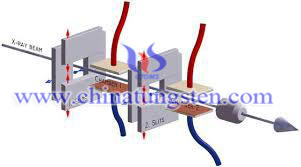

For industrial radiography using gamma radiation sources such as Iridium-192 or Cobalt-60, a tungsten alloy collimator (beam limiting device) allows the radiographer to control the exposure of radiation to expose a film and create a radiograph, to inspect materials for defects. A tungsten alloy collimator in this instance is most commonly made of tungsten alloy foils, and is rated according to how many half value tungsten alloy layers it contains, i.e., how many times it reduces undesirable radiation by half. For instance, the thinnest walls on the sides of a 4 HVL tungsten alloy collimator 13 mm (0.52 in) thick will reduce the intensity of radiation passing through them by 88.5%. The shape of these collimators allows emitted radiation to travel freely toward the specimen and the x-ray film, while blocking most of the radiation that is emitted in undesirable directions such as toward workers.

The photograph below shows tungsten alloy materials to manufacture collimator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Collimator in Radiation Therapy

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 18:15

Tungsten alloy collimators (beam limiting devices) are used in linear accelerators used for radiotherapy treatments. Tungsten alloy collimators help to shape the beam of radiation emerging from the machine and can limit the maximum field size of a beam.

The treatment head of a linear accelerator consists of both a primary and secondary collimator. The primary collimator is positioned after the electron beam has reached a vertical orientation. When using photons, it is placed after the beam has passed through the X-ray target. The secondary collimator is positioned after either a flattening filter (for photon therapy) or a scattering foil (for electron therapy). The secondary collimator consists of two jaws which can be moved to either enlarge or minimize the size of the treatment field.

New systems involving tungsten alloy multileaf collimators (MLCs) are used to further shape a beam to localize treatment fields in radiotherapy. Tungsten alloy multileaf collimators consist of approximately 50–120 leaves of tungsten alloy collimator plates which slide into place to form the desired field shape.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Carbide Tools Development Stage

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 16:33

There are four stages of coated carbide tools development: the late 1960s, early 1970s, the mid-1970s and the present stage.

The late 1960s is the beginning stage of coated carbide tools development stage. In this period, coated carbide tools based on TiC coated carbide tools, The second generation of coated carbide tools approximately appear in the early 1970s, when a number of improvements were made to the TiC coating, control coating and the substrate between large brittle n phase thickness, and the development of TiN, Al2O3, such as single coat and the foregoing two-coat and three-coat, such as TiC-TiN, TiC-Al2O3 and the like. The third generation of coated carbide tools was developed in the mid-1970s, in addition to the above several coating materials, also tested the new coating materials and coating more than three coating and the development of the coating material matching special carbide substrate, the strength properties of the coating blade has been further improved. At present, development of coated carbide tools focuse on new coating materials, including diamond, cubic boron nitride and carbon nitride coated tools, etc.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ultra-Fine Grain Tungsten Carbide Cutting Tools Application Status

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 16:32

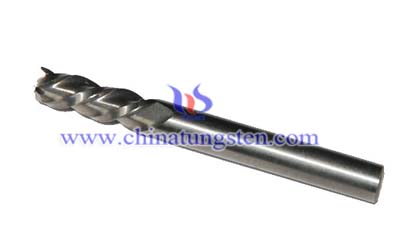

Ultra-fine grain tungsten carbide cutting tools is a kind of high hardness, high strength and high wear resistance of tungsten carbide cutting tools, which has high strength of alloy high and high hardness of high-speed steel. Ultra-fine grain tungsten carbide cutting tools is now widely used in modern manufacturing.

One aspect of ultra-fine grain tungsten carbide cutting tools application status is that because a clear advantage in terms of modern high-speed cutting difficult materials, titanium, coating materials, hardened steel, ultra-fine grain tungsten carbide cutting tools is now made of a rod tools, processing integrated circuit board micro drill, dot matrix printer needle, the overall processing tools, milling cutters, drills, woodworking tools and precision molds.

Another aspect of ultra-fine grain tungsten carbide cutting tools application status is that ultra-fine grain tungsten carbide cutting tools can also be used to produce small-size solid tool for high-speed machining hole, gear and tapping may be at a higher speed machining titanium and its alloys and superalloys superalloy. On the other hand, high strength, high hardness of ultra-fine grain tungsten carbide cutting tools can also be made of solid carbide end mills, in order to ensure its center of cutting edge.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Market Forecast

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 16:32

According to the tungsten carbide cutting tools market forecast made by China's machine tool industry association tools branch,in the next five years, China's market of tungsten carbide cutting tools will remain higher than the overall GDP growth rate, a conservative forecast of 10% -15%; high-end carbide With the industrial upgrading of the tool and to further improve the level of equipment, will continue to maintain high growth, it is expected to grow more than 15%.

In addition, according to China's "tool industry," second Five Year Plan "(draft recommendation)," an explicit proposal to significantly improve efficiency of domestic tungsten carbide cutting tools in manufacturing high-end market share, targets the high-end market share to From around the current 15% to 30% -40%; and conceive again 2-3 five-year plan period, so that the localization rate gradually increased to the average level of developed countries, 60% -70%. To accomplish this goal, the localization rate of average annual growth rate will reach 20%. It can make another tungsten carbide cutting tools market forecast: production of tungsten carbide cutting tools will also reach a new historical level during"Twelve Five" period.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Insert Shape

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 15:10

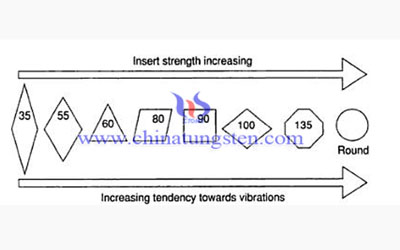

Generally the selection of the insert shape of a tungsten carbide cutting tool is depends on the work material, the required production rate and the condition of the machine tool. And the shape of a tungsten carbide insert is specified by the first letter of the insert designation, which include diamond, triangle ,square,octagon, round and trigon.

Furthermore, the shape of an insert largely determines the carbide tool ‘s strength, quantity of cutting edges and the total cost. It is claimed that when the insert becomes stronger and dissipates heat more rapidly as its included angle is increased, so there’s a trade-off between strength and versatility during the insert shape selection. For instance, round inserts is an ideal option for roughing operation considering it could offer maximum edge strength, while the square inserts are popular in general purpose due to its good edge strength and bunch of cutting edges.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

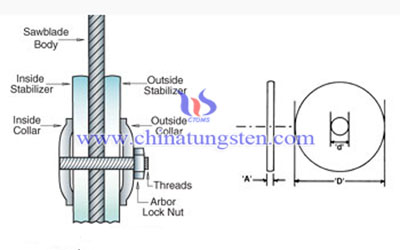

Tungsten Carbide Saw Blade Stabilizers

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 15:07

Since carbide saw blades are circular, they are radially the stiffest elements of the power train in the direction of the feed, but very unstable perpendicular to the feed direction. Due to the thin blade body the blades must be stabilized to minimize the side vibration amplitudes. When the first experiments with carbide saws were made, the blade stabilizer was developed using two plastic coated ball bearings mounted on eccentric shafts and supported by a welded bracket to the gearbox. Recently the new patten has been developed, a pair of front stabilizers for machines arranged close to the point at which the blade enters the material. These stabilizers hydraulically extend, when the carbide teeth have moved past the stabilizer tips before cutting and stabilize the blade which also help to guide the blade into the cut to improve the accuracy.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

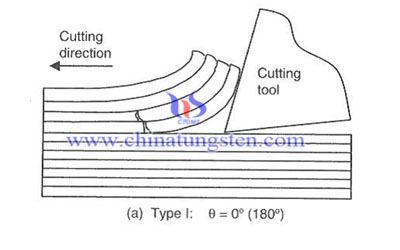

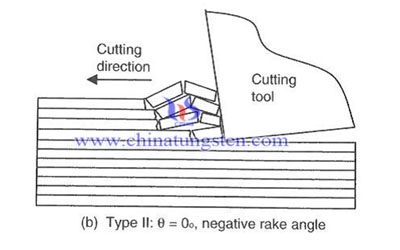

Tungsten Carbide Hand Cutting Tool Rake

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 15:02

For a tungsten carbide hand cutting tool involved in axial milling, there are several rake angles to be addressed, all addressing cutting forces for a given material. Side rake is relative to cutting edge. With positive tungsten carbide hand cutting tools the rake is in the tool, for negative tools, the rake is relative to the position of the tool to the center line. Since there’s no clearance in negative inserts, clearance is provided by normally having a 5 to 7 deg negative rake and side rake for clearance to avoid rubbing. Shear plane is recognizing as the shearing of metal at a given plane, that is relative to the cutting edge. A negative plane offers less shear, more pushing of the material, more horsepower and a stronger edge engaged in the cut zone. A positive plane reduces cutting forces offers freer cutting, less horsepower and a weaker cutting edge. Clearance is the angle below or behind the cutting edge.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Saw Bit Tooth Angle (2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 May 2015 14:50

Back Angle

It is the angle between tungsten carbide serrated blade and the machined surface, typically the angle is 15 degrees. Its role is to prevent jagging and machined surface friction, the greater the back angle, the smaller the friction will be, it also suggests more smooth processing processes.

Wedge Angle

It is the derived corner of front corner and rear corner . The wedge angle can not be too small, it plays a role in keeping the teeth strength, heat resistance and durability. Specially the sum of the front angle, back angle and the wedge angle should be equal to 90 degrees.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com