Tungsten Alloy Radiation Detector in CAT Scanner

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 18:43

A computed tomography (CT) or computerized axial tomography (CAT) scanner is a medical imaging tool that provides clear pictures of the internal structures of the body. Utilizing a beam of x rays and a tungsten alloy radiation detector, it supplies data to a computer, which then constructs a three-dimensional image.

A wide variety of materials, such as tungsten alloy, glass and plastic, are used to construct the components of a CAT scanner. Some of the more specialized compounds can be found in the patient couch, detector array, and the x-ray tube. CAT scanners use X-ray technology to create three-dimensional images of the body's internal structures. Images are obtained by rotating the X-ray generator and tungsten alloy radiation detectors around the patient. This information is fed into a computer, which reconstructs images of the body structures within its plane of focus.

The tungsten alloy radiation detector array of more modern scanners uses tungsten alloy plates, a ceramic substrate, and xenon gas. Tungsten alloy is also used to make the cathode and electron beam target of the X-ray tube. Other materials found in the tube are glass, copper, and tungsten alloy. Throughout many parts of the CAT scanner system, lead can be found, which reduces the amount of excess radiation.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Geiger-Mueller Detector with Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 18:39

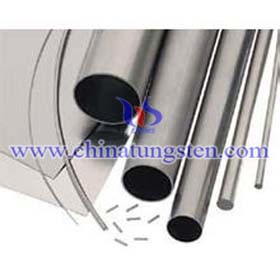

Geiger-Mueller detector is a radiation detection and measuring instrument. It consists of a gas-filled tube containing electrodes, between which there is an electrical voltage, but no current flowing. When ionizing radiation passes through and ionizes the gas within the tungsten alloy tube a short, intense pulse of current passes from the negative electrode to the positive electrode and is measured or counted.

A highly sensitive Geiger-Mueller radiation detector with improved temperature stability and working life uses a cathode liner made of tungsten alloy. The tungsten alloy liner is resistant to attack by the halogen quench gases which are used in the detector. The method of conditioning the tungsten alloy tube for use is much simpler and less expensive than it is for existing tubes.

Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation.A thin layer of tungsten alloy can be used on the inside surface of a cylindrical cathode to give a Geiger-Mueller detector having high sensitivity and outstanding resistance to the halogen gas. Furthermore, it is surprising and unexpected that the tungsten alloy layer can be applied to the interior of a cylindrical cathode as a thin tungsten alloy foil thus omitting the necessity of electrodepositing the layer on the interior surface.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Saw Machine Stiffness

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:52

When a circular carbide-tipped saw blade enters or exits the material, only one tooth is cutting. The fluctuation of the load, when the tooth enters and exits the cut, induces vibrations and requires a very stiff gear box and machine.

A pivot saw has the highest degree of stiffness, because the forces are arranged in a closed loop. If we assume that the base of such a saw is very rigid, the force will flow from the pivot of the gearbox to the ball screw feed system in a closed loop, whereby the cutting force engages in the middle, approximately, between rotation point and ball screw. This arrangement substantially reduces the lost motion and compliance in the feed system. Furthermore the ball screw drive which forces the blade into the cut is bolted to the fixture frame which again is clamped to the billet and gives this arrangement additional rigidity.Saws with horizontal or tilted slides have an open loop force flow and maintain any lost motion and compliance of the feed system.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Saw Types (1)

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:52

Carbide saws with inclined ways

Compared to the conventional horizontal slide saw, the price inclined ways of carbide saw are higher. However, they are identified as most effectively cutting railroad rails saw types due to the saw blade could enter into the rail profile optimally.

Pivot saws

The pivot saw cuts on both sides of the pivot axis, one bar each with the center of rotation of the gearbox was mounted to the floor plate. In order to achieve a more more productive performance,a high-efficiency carbide saw where the pivot axis of the gearbox is fixed on the lower end of the machine bed, for cutting 350 mm (14") billets, has been produced. The force is contained in a close loop and the machine is extremely stiff. In this machine the chip flow is also improved, as the chips are thrown directly onto the chip conveyor.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool with PIM Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:42

Carbide tools are used in machining tough materials with higher quantity production runs,better finish on the part, and allow faster machining. Powder injection molding (PIM) is a manufacturing solution for producing intricate parts in medium to high volumes (10,000 to over 2,000,000 parts annually) using fine (<20 μm) metal or ceramic powders. PIM processes were used to fabricate the proposed carbide alloyed composite parts, which is capable of transforming complex concepts & designs into high precision, high final properties, and net-shaped carbide tools.

PIM is well suited for carbide products weighing from 0.1gm to 250 gm. Cross sections are typically less than 0.25 in. (6.35 mm). However, carbide tool parts are not restricted to this combination of mass and cross section. Tolerances are on the order of ±0.3 to 0.5%, albeit specific dimensions can be held as close as ±0.1%.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Saw Teeth Fasten Procedures

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:29

Carbide saws teeth are made of cemented carbide, which are suitable machine tools for hard materials cutting.

If a carbide tooth is at a saw blade, the suggested fastening procedures are listed as follows, firstly fabricated according to the saw tooth geometry being held butt-jointed to the prepared front-side abutting surface of the saw blade and then being attached to the saw blade under addition of heat along the joint between the saw blade and the carbide tooth .

To create favorable process conditions it is suggested that the carbide tooth is welded to the saw blade by means a focal spot of a laser beam extending over the whole joint length.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Saw Types

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:22

The initial carbide saw was a machine tool with a circular saw blade and silver soldered carbide tips. At present the most popular carbide saw types comprise as follow,

Saw with horizontal slides

One of the most commonly used type of carbide saw. With this design the saw blade is mounted on the gearbox spindle, where it slides on horizontal ways and enters horizontally into the billet. The design idea was adopting telescopic steel way covers and steel aprons to protect the vital components of the saw from high flying chips that are difficult to control.

Saws with vertical slides

In order to take over the production of this type of machine and also built it as a layer saw. The inventor had previously built vertical HSS saws with double round ways and converted them later into carbide saws.Thereafter , the saw blade for this type of saw enters vertically into the material. These saws are often used as layer saws, whereby a multitude of tubes, profiles, or bars can be simultaneously cut horizontally.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Manufacture Process of Tungsten Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:19

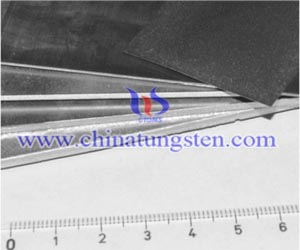

Tungsten heavy alloy materials are used for shielding applications as collimators in medical imaging diagnostics and therapy. Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation.

The tungsten heavy alloy collimator manfaucturing process including mixing, binding, debinding, pressing, and sintering, machining.

In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets for collimators, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield. The process comprised the mixing of a tungsten alloy powder (such as: with content of 92.5 et.% W and the balance of Ni, Fe) with an organic binder, thermoplastic shaping of mixture to a green sheet material by an extrusion process, followed by debinding and sintering. The sintering step was performed in hydrogen atmosphere under liquid phase sintering conditions at a temperature range of 1450°C to 1500°C. Depend on the different needs of customers,tungsten alloy sheets can be produced into sheets and foils for a thickness range of below 0.1 until 4 mm in collimator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Thicknesses of Tungsten Heavy Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:17

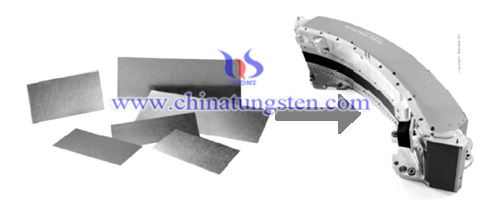

In the case of X-ray diagnostics, typical applications are collimators in the detector system and shielding parts in computer tomography. Most of these components are sheet based applications with a thickness range of about 0.1mm to 2mm. The replacement of the widely used shielding material lead (Pb) was intensified and activities on the search for substitutes have been significantly increased, the new alternative material should be tungsten heavy alloy.

Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation. For this reason tungsten heavy alloy materials are used for shielding applications as collimators in medical imaging diagnostics and therapy.

The fabrication of tungsten heavy alloy thin sheets with a thickness of below 1.5 mm (preferably below 0.4 mm) by tape casing technology was already reported. The near net shape produced of sheets and foils for a thickness range of below 0.1 until 4 mm was developed. In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets for collimators, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield. Due to the developed technology, foil material of thickness below 0.1 and sheet material of thickness up to 3 mm can be produced .

The figure below shows tungsten heavy alloy foil and sheet material of thicknesses 0.09 to 3 mm.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cost Efficiency of Tungsten Heavy Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:13

Due to the excellent shielding against electromagnetic radiation, tungsten based materials are typically used for collimators components in medical imaging diagnostics. However, the conventional manufacturing of pure tungsten sheet and foil material is quite expensive because of high temperature sintering and thermo-mechanical treatment.

A cost and material efficient manufacturing for tungsten based material has been developed. The new technology uses dedicated mixtures of tungsten heavy alloy powder and organic binder, which are formed and sintered to full-metallic semi-finished products. Due to the tungsten content of ≥ 90 wt.% the material exhibits excellent X-ray absorption. Furthermore the full-metallic material overcomes possible drawbacks of tungsten filled polymers with respect to aging and degradation under X-ray radiation. Sheets up to 4mm thickness and foils down to below 100μm can be produced in tight tolerances. The isotropic microstructure allows the forming of structural parts by roll bending and deep-drawing technologies.

In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield and further the saving of expensive thermo-mechanical processing steps. Material and cost efficient manufacturing route for tungsten heavy alloy foil and sheet material for collimators was developed. The technology established is the metal extrusion moulding where dedicated mixtures of tungsten heavy alloy powder and organic binder are formed and sintered to full-metallic semi-finished products.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com