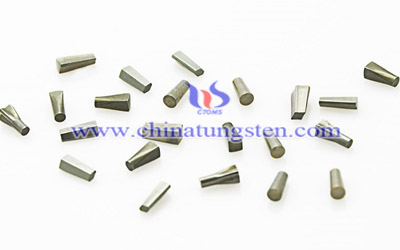

Carbide Tool with PIM Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:42

Carbide tools are used in machining tough materials with higher quantity production runs,better finish on the part, and allow faster machining. Powder injection molding (PIM) is a manufacturing solution for producing intricate parts in medium to high volumes (10,000 to over 2,000,000 parts annually) using fine (<20 μm) metal or ceramic powders. PIM processes were used to fabricate the proposed carbide alloyed composite parts, which is capable of transforming complex concepts & designs into high precision, high final properties, and net-shaped carbide tools.

PIM is well suited for carbide products weighing from 0.1gm to 250 gm. Cross sections are typically less than 0.25 in. (6.35 mm). However, carbide tool parts are not restricted to this combination of mass and cross section. Tolerances are on the order of ±0.3 to 0.5%, albeit specific dimensions can be held as close as ±0.1%.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com