Tungsten Alloy Advantages in GM Detector

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 18:28

In a Geiger-Mueller radiation detector(GM detector) including a relatively large surface stainless steel cathode, a coating of chromium oxide on the interior surface of said cathode. It has been found that a thin layer of tungsten alloy can be used on the inside surface of a cylindrical cathode to give a GM detector having high sensitivity and outstanding resistance to the halogen gas.

Furthermore, the tungsten alloy layer can be applied to the interior of a cylindrical cathode as a thin foil thus omitting the necessity of electro depositing the tungsten alloy layer on the interior surface.

Considerable significance is the fact that a stainless steel GM tube in which the interior surface of the cathode is coated with a thin layer of chromium oxide and a tungsten alloy foil liner possesses remarkable high temperature stability even though it is not subjected to the thermal cycling or bromine passivation techniques.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

High Spatial Resolution Radiation Detector with Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 17:38

The present invention provides improved spatial resolution (100 microns or less) for charge particle detection or cold neutron detection with extremely low sensitivity to other radiation such as x-rays or gamma rays, defining the time of the event within nanoseconds. Depending on how it the invention is implemented, the spatial resolution can be larger or smaller than 100 microns as desired. The present invention is simpler than existing methods for such applications. Due to the excellent radiation absorption of tungsten alloy, it can be produced into sheets and foils for a thickness range of below 0.1 until 4 mm in radiation detector. Higher signal of tungsten alloy radiation detector to noise ratio results in lower false detection rates and higher real detection. The scintillation end of the fiber can be made by ion implantation or thermal diffusion.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Drill Bit

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 11:26

A tungsten carbide drill bit is a device part made of carbide, attached to the end of the drill string that breaks apart, cuts or crushes the rock formations when drilling a wellbore, such as those drilled to extract water, gas, or oil.

The carbide drill bit is hollow and has jets to allow for the expulsion of the drilling fluid, or "mud", at high velocity and high pressure to help clean the bit and, for softer formations, help to break apart the rock. A tricone carbide bit as a improved design that comprises three conical rollers with teeth made of tungsten carbide. The teeth break rock by crushing as the rollers move around the bottom of the borehole. A polycrystalline diamond compact (PDC) bit has no moving parts and works by scraping the rock surface with disk-shaped teeth made of a slug of synthetic diamond attached to a tungsten carbide cylinder.PDC bits, which first came into widespread use, are used for gas and oil exploration in the North Sea. They are effective at drilling shale formations, especially when used in combination with oil-base drilling muds.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Dental Drill

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 11:23

A carbide dental drill is a small, high-speed carbide drill used during dental procedures, usually to remove decay and shape tooth structure prior to the insertion of a filling or crown. A carbide dental drill may also be used in the cleaning and shaping of root canals during endodontic treatment, or to remove old or temporary fillings or crowns prior to the insertion of new or permanent restorations.

Modern carbide dental drills can rotate at up to 400,000 rpm, and generally use hard metal alloy bits known as burs. Dental burs come in a great variety of shapes designed for specific applications. They are often made of steel with a tungsten carbide coating, or of tungsten carbide entirely. The bur may also have a diamond coating.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Dental Bur

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 11:22

Carbide dental bur is a type of cutter used in a dental drill, including three parts the head, the neck, and the shank. The carbide burs are made of tungsten carbide.

The heads of tungsten carbide burs contain the blades that remove material. These blades may be positioned at different angles in order to change the property of the bur. More obtuse angles will produce a negative rake angle which increases the strength and longevity of the bur. More acute angles will produce a positive rake angle which has a sharper blade, but which dulls more quickly. The heads of other commonly used burs are covered in a fine grit which has a similar cutting function to blades.

There are various shapes of burs that include round, inverted cone, straight fissure, tapered fissure, and pear-shaped burs. Additional cuts across the blades of burs were added to increase cutting efficiency, but their benefit has been minimized with the advent of high-speed handpieces. These extra cuts are called crosscuts.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Models of Carbide Saw (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 11:20

The initial carbide saw was a machine tool with a circular saw blade and silver soldered carbide tips. Some special carbide saws are listed as follow,

Plate Saw

It is developed by meaning of cutting plates made of high-strength carbon steel using carbide saw blades. The horizontal ways were mounted on a beam above the plate. Furthermore, a plate saw where the gearbox slid underneath the plate on a machine bed and cut the plate from below was produced.

Railroad Rail Saw

It is a special model of a carbide saw for miter cutting railroad rails for frogs and switches. Recently it has been developed to a special model which is integrated as a double saw in a railroad car and used for repair work of railroad tracks in the USA. It replaced abrasive saws which had been used before. Because these abrasive saws were guilty of causing forest fires due the hot chips and sparks, later these hazardous machines were replaced with cold saws.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Models of Carbide Saw(2)

- Details

- Category: Tungsten Information

- Published on Thursday, 14 May 2015 11:17

Layer Saw

A two layer saws that cut the ends of up to six "C" profiles. The profiles approached the saws horizontally, in layers. Specially a vertical design was produced later after that. The first saw cut the front ends, the second the rear ones, whereby the latter was movable on tracks and which therefore cut different lengths. These machines were built as pivot saws and cut from the bottom up through the profiles. It was also used for cutting tubes in layers.

Carbide hot saws

A carbide hot saw which cut off the ends on hot-forged axles.

Carbide Ring Saw

Thick-walled rings are hot-rolled and often have to be cut in slices. For different designs, such a saw could cut these rings from the inner diameter and also from the outside.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Usage of Tungsten Alloy in Gas-Filled Radiation Detectors

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 19:00

A gas-filled radiation detector is usually a glass tube that contains two concentric electrodes and a gas such as argon. The outer electrode is a metal tube; the inner electrode is a wire stretched between the ends of the tube along its axis. Energetic charged particles, X-rays, or gamma rays entering the detector strip electrons from the gas atoms to produce positively charged ions and negatively charged electrons. Due to the excellent shielding against electromagnetic radiation, tungsten alloy materials are typically used for gas-filled radiation detector components. An electric field created by several hundred volts or more across the electrodes draws the ions to the negative electrode and the electrons to the positive electrode. The electron flow produces a current pulse, which is the detection signal. The charge produced by a 1-million-electronvolt charged particle coming to rest in the gas is about 5 fem to coulombs.

The magnitude of the electric field that made of tungsten alloy determines the detector's mode of operation. As it is high density, tungsten alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation. The field made of tungsten alloy is high enough to prevent the electron-ion pairs produced by the radiation. In order of increasing electric field, the detector operates as an ionization chamber, a proportional counter, or a Geiger-Muller tube. The modular neutron detector operates as an ionization chamber.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Testing Tungsten Alloy in Collimator

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 18:47

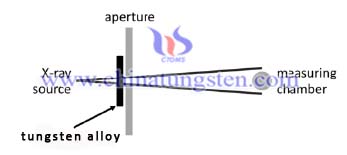

Characterization of the microstructure was performed on metallographic sections by light microscopy. Tensile testing was carried out RT, 300 and 500°C according to DIN EN 10002 part 1 and 5 respectively. The tungsten alloy samples were taken in different orientations from 0.8 mm thick sheets. Investigations of the fracture surface of the ruptured samples by SEM gave information about the deformation machanism as function of processing route and test temperature. Tungsten alloy collimator testing was tested in comparison to conventionally produced tungsten and tungsten ally at Physikalisch-Technische Bundessanstalt.

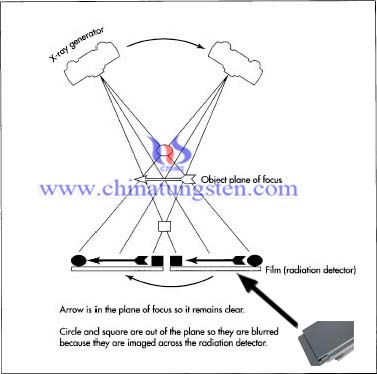

Using sheets material of different thicknesses the change in X-ray beam intensity was measured in a test setup of ‘narrow beam’(as shown in the figure) and the liner attenuation coefficient was determined for tube voltages of 50 to 150 kV.Based on the air-kerma, which is the absorbed X-ray dose in air,the equivalent lead thickness of the different materials was calculated as a function of the tube voltage.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Tungsten Alloy Radiation Detector be Produced in CAT Scanner

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 18:46

A computed tomography (CT) or computerized axial tomography (CAT) scanner is a medical imaging tool that provides clear pictures of the internal structures of the body. CAT scanner manufacture is typically an assembly of various components. The following process discusses how the major components are produced.

Gantry assembly components

1 The x-ray tube is made much like other types of electrical diodes. The individual components, including the cathode and anode, are placed inside the tube envelope and vacuum sealed. The tube is then situated into the protective housing, which can then be attached to the rotating portion of the scanner frame.

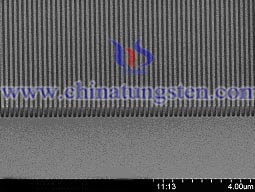

2 Tungsten alloy radiation detector arrays are available for CAT scanners. One type of tungsten alloy detector array is the ideal gas-filled detector. This is made by placing strips of tungsten 0.04 inch (1 mm) apart around a large metallic frame. A ceramic substrate holds the strips in place. The entire assembly is hermetically sealed and pressure filled with an inert gas such as xenon. Each of the tiny chambers formed by the gaps between the tungsten alloy plates are individual detectors. The finished detector is also attached to the scanner frame.

3 To create the large amount of voltage needed to produce x rays, an autotransformer is used. This power supply device is made by winding wire around a core. Electric tap connections are made at various points along the coil and connected to the main power source. With this device, output voltage can be increased to approximately twice the input voltage.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com