How Tungsten Alloy Radiation Detector be Produced in CAT Scanner

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 18:46

A computed tomography (CT) or computerized axial tomography (CAT) scanner is a medical imaging tool that provides clear pictures of the internal structures of the body. CAT scanner manufacture is typically an assembly of various components. The following process discusses how the major components are produced.

Gantry assembly components

1 The x-ray tube is made much like other types of electrical diodes. The individual components, including the cathode and anode, are placed inside the tube envelope and vacuum sealed. The tube is then situated into the protective housing, which can then be attached to the rotating portion of the scanner frame.

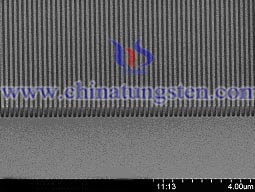

2 Tungsten alloy radiation detector arrays are available for CAT scanners. One type of tungsten alloy detector array is the ideal gas-filled detector. This is made by placing strips of tungsten 0.04 inch (1 mm) apart around a large metallic frame. A ceramic substrate holds the strips in place. The entire assembly is hermetically sealed and pressure filled with an inert gas such as xenon. Each of the tiny chambers formed by the gaps between the tungsten alloy plates are individual detectors. The finished detector is also attached to the scanner frame.

3 To create the large amount of voltage needed to produce x rays, an autotransformer is used. This power supply device is made by winding wire around a core. Electric tap connections are made at various points along the coil and connected to the main power source. With this device, output voltage can be increased to approximately twice the input voltage.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com