Why Use Tungsten Alloy as Detector System

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 19:24

Due to tungsten alloy is high density and atomic mass, tungsten alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and γ-radiation . The absorption of x-ray and gamma radiation is in direct proportion to the density of the shielding material. Tungsten alloy are more than 1.5 times as effective as lead and provide extremely efficient protection, particularly where space is limited.For this reason, tungsten alloy based materials are used for shielding applications in medical imaging diagnostics and therapy. In the case of X-ray diagnostics, typical applications are collimators in the tungsten alloy detector system and shielding parts in computer tomography.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Woodworking Tools Application

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:41

Since cemented carbide woodworking tools are used for working solid wood, such as logs etc. Its application also includes man-made products based on wood particles, fibres or chips, such as chipboard, particle board and medium and high density fiber boards (MDF/HDF), the different types of corrosion are important: solid wood contains organic acids and other compounds that degrade the binder in the tool material and cause outbreak of the hard WC-particle from the matrix and thus wear the tool material.

Man-made wood products contain organic binder material, based on compounds such as urea, formaldehyde, wax, glue fillers etc. and possibly laminated with plastic layers, such as melamine. The temperature may get very high (>500°C) when working these wood products and then the content of the product will degrade into corrosive compounds chemically attacking the cemented carbide binder.

Furthermore the high temperature may result in oxidation of the cemented carbide binder, also degrading and wearing the cutting edge.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

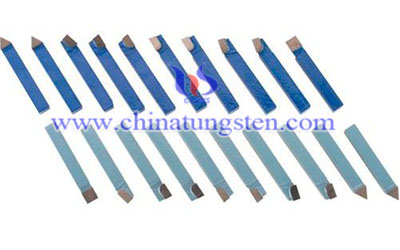

Carbide Tipped Tools Grade Selection

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:39

Carbide tipped tools are far more durable than solid carbide tools. Under abnormal conditions the carbide may start to crack due to hard spots in the material being machined, incorrect feed rates or inadequate holding of workpiece. These cracks that shatter solid carbide tools are stopped in carbide tipped tools by the tough hardened tool steel body - usually permitting the tool to complete the production run.

The carbide grade in carbide tipped tools can be selected wholly based on its cutting and wear characteristics rather than compromising for the carbide's structural strength, as is required for solid carbide tools. Some high cost specialty carbides necessary for aggressive machining of many tough alloys are not even available in solid carbide round form.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Woodworking Tools

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:38

Cemented carbide is one of the most common materials currently being used in the wood industry for woodworking tools. In the quest for extended lifetime of the woodworking tools and for cutting quality it is important to optimise specific properties of the cutting tool material. Two of the most important properties of the woodworking tool are the resistance to corrosion and oxidation and the hardness.

A cutting tool for woodworking applications has a tungsten carbide substrate and a hard layer bonded to the substrate at high temperature and high pressure, i.e. where diamond or cubic boron nitride is thermodynamically stable. The hard layer comprises polycrystalline diamond or polycrystalline cubic boron nitride, and a supporting cobalt phase including adjuvant alloying materials for providing oxidation and corrosion resistance. Typical alloying elements include nickel, aluminum, silicon, titanium, molybdenum and chromium. Such materials also retard transformation of cobalt from the HCP to the FCC crystal structure at high temperature. The hard layer has an as-pressed surface parallel to the substrate and is only about 0.3 millimeters thick. An additional secondary phase including a carbide, nitride and carbonitride of metals such as titanium may also be present in the PCD or PCBN layer.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tipped Tools Advantages

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:36

Generally the advantages of carbide tipped tools can be concluded as follow,

1.Carbide tipped tools are far more durable than solid carbide tools.

2.Carbide tipped tools retain their cutting edge hardness at high machining temperatures generated by high cutting speeds and feeds that reduce machining cycle time.

3.Carbide tipped tools improve surface finish and hold size far longer for better quality.

4.Carbide tipped tools last far longer because the carbide chip forming surface resists wear as the chip flows over the tools. This greatly reduces need for costly changes with increased scrap and rework.

5.Carbide tipped tools should always be used when machining highly abrasive materials.

Although carbide tipped tools use higher quality more costly carbide, the overall cost is usually substantially less than solid carbide tools because only the thick cutting edge is carbide.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Rotary Tool Cutting Edge Portion Intermediate Form

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:28

A carbide rotary tool cutting edge portion intermediate form that is an intermediate form of the cutting edge portion, the cutting edge portion intermediate form having a recessed portion that defines a bottom face and an inner circumferential surface.

Tthe cutting edge portion intermediate form being made from cemented carbide that has been pre-sintered at a second temperature that is lower than the first temperature; inserting the front end of the support portion intermediate form into the recessed portion provided in the cutting edge portion intermediate form; and sintering the cutting edge portion intermediate form and the support portion intermediate form together in a state of double face contact in which the end face of the front end of the support portion intermediate form is in direct contact with the bottom face of the recessed portion and the outer circumferential surface of the front end of the support portion intermediate form is in direct contact with the inner circumferential surface of the recessed portion.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Rotary Cutting Tool

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:25

Carbide rotary cutting tools (i.e., cutting tools driven to rotate) are commonly employed in machining operations such as, for example, drilling, reaming, countersinking, counterboring, end milling, and tapping. Such tools are conventionally manufactured with a non-hybrid solid monolithic construction. The manufacturing process for such tools involves consolidating metallurgical powder (comprised of particulate ceramic and metallic binder) to form a compact. The compact is then sintered to form a cylindrical tool blank having a monolithic construction. As used herein, the term “monolithic construction” means that a tool is composed of a solid material such as, for example, a cemented carbide, having substantially the same characteristics at any working volume within the tool. Subsequent to sintering, the tool blank is appropriately machined to form the cutting edge and other features of the particular geometry of the rotary cutting tool. Rotary cutting tools include, for example, drills, end mills, reamers, and taps.

Rotary cutting tools composed of cemented carbide are adapted to many industrial applications, including the cutting and shaping of materials of construction such as metals, wood, and plastics. Tools made of cemented carbide are industrially important because of the combination of tensile strength, wear resistance, and toughness that is characteristic of these materials.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide End Mills

- Details

- Category: Tungsten Information

- Published on Friday, 08 May 2015 11:20

A cemented carbide end mill includes a shank and a blade joined to the leading end of the shank which are each made of the cemented carbide alloy. In the manufacturing process of the cemented carbide end mill, first, a shank intermediate manufacturing process for manufacturing a shank intermediate product, which is the half-sintered product of the shank, and a blade intermediate product manufacturing process for manufacturing a blade intermediate product, which is the fully sintered product of the blade, are respectively carried out, secondly, the protrusion of the blade intermediate product is inserted into an insertion hole in the shank intermediate product to form an integrated chip intermediate product. The chip intermediate product is fully sintered, and then cobalt grains are liquid-phase-sintered at a boundary part between the inner circumferential surface of the insertion hole of the shank intermediate product and the outer circumferential surface of the protrusion of the blade intermediate product. Accordingly, the shank intermediate product and the blade intermediate product are strongly joined each other.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Application of Tungsten Alloy Counterweight in Sports Equipment-Badminton Racket

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2015 20:25

Most material used in badminton racket has good strength, good durability and resistance to vibration and shock performance.But they can not meet the demand of higher weight.Every badminton racket need to label its weight when in the match. General standard is U, 2U, 3U, 4U.Mostweight of the carbon badminton racket is 2U (90-94 g) or 3U (85-89 g), 4U (80-84), and alumium badminton racket is generally u(95-99 g), there are a few all-carbon badminton rackets’weight is down to 80 grams.When it be use is too lightweight to be drift, smash is insufficient,and can not be strength and emphasis enough on offensive players.Since the weight of tungsten alloy counterweight that may meet the need of badminton rackets, tungsten alloy badminton racket counterweight become the most popular badminton racket in match.

Balance point of badminton racket is closer to the head of the racket, is called "head heavy".If the balance point closer to the handle of the paddle, it is called "head light".General equilibrium is from the bottom of the racket up, measured in centimeters and inches.Tungsten alloy badminton racket counterweight is more suitable for Defense, and control of players as well as the pursuit of speed players, because of the racket of the continuous swing speed will be a lot faster.Through the using of tungsten alloy counterweights can make the same type of badminton racket of with different balance point.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Application of Tungsten Alloy Counterweight in sports Equipment-Golf Club Head

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2015 20:23

Golf Club Head: golf club head counterweight includes a balance, balance of golf club heads.Cobra-like tungsten alloy golf counterweights are from multiple weights and snake eyes and golf club heads.Formed a weight cavity install tungsten golf ball counterweight is now a significant part of this golf club balance weight material.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com