Carbide Tool Titanium Oxide Layers

- Details

- Category: Tungsten Information

- Published on Monday, 11 May 2015 12:01

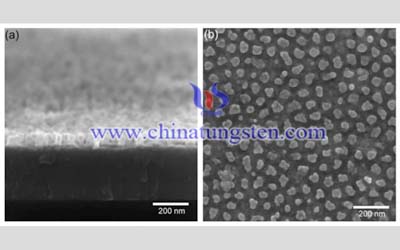

In recent years, it has been suggested that improved tool life of tungsten carbide tools containing titanium carbide was caused by the formation of titanium oxide layers, and in some cases sulfide layers and other oxides, on the surface of the tool. This belief was based upon the showing by electron microscopy that a protective and adherent layer of Ti2 O3 was present as an intermediate layer between a TiC-TiO solid solution on the surface of the carbide tool after cutting.

It has been more recently shown that by application of cutting fluids, sulfide and oxide layers are formed in the contact zone of a carbide cutting tool and an aluminum-deoxidized steel, in which case the sulfide and oxide layers are less than 10 μm thick. It has been asserted in the prior art that the oxide layer formed on the surface of the tungsten carbide tool raises the welding temperature between the carbide tool and steel by several hundred degrees, thereby decreasing wear by the "adhesion-and-shear" process. In addition, it has also been asserted that TiO is very adherent to the carbide surface of the tool since the sub-surface forms a solid solution of TiO and TiC. Thus, it was believed that the role of the surface layer was that of reducing the frictional coefficients and preventing diffusion and the like between the tool and the workpiece.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com