Unsung Heroes in Medicine: Tungsten Alloy Shielding Components

- Details

- Category: Tungsten Information

- Published on Monday, 04 August 2025 16:16

In the context of continuous advancements in modern medical technology, a variety of sophisticated diagnostic and treatment methods have brought hope to patients. However, while these technologies play a crucial role, they also introduce unavoidable radiation risks. Take radiotherapy, for example, which is a key method in cancer treatment, utilizing high-energy rays to destroy cancer cells. During this process, while the rays target cancer cells, they also affect surrounding healthy tissues. Radiotherapy can lead to radiation dermatitis, causing skin redness, itching, peeling, or even ulceration in patients; it may also result in radiation pneumonitis, leading to symptoms such as coughing, shortness of breath, and difficulty breathing. Beyond the physical harm to patients, radiotherapy may pose long-term health risks, including an increased likelihood of second primary tumors, undoubtedly making the road to recovery more challenging. Similarly, CT scans, a commonly used medical imaging method, enable doctors to clearly observe internal human structures and play a vital role in disease diagnosis. However, the X-rays used in CT scans, being ionizing radiation, can impact human cells.

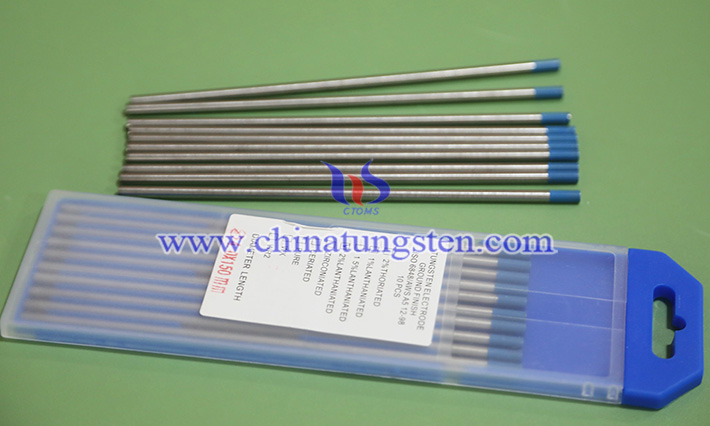

How Is the Adaptability of Lanthanum Tungsten Electrodes in Automated Welding Equipment?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:39

With the continuous improvement of industrial automation, automated welding equipment is becoming increasingly widely used in the manufacturing industry.

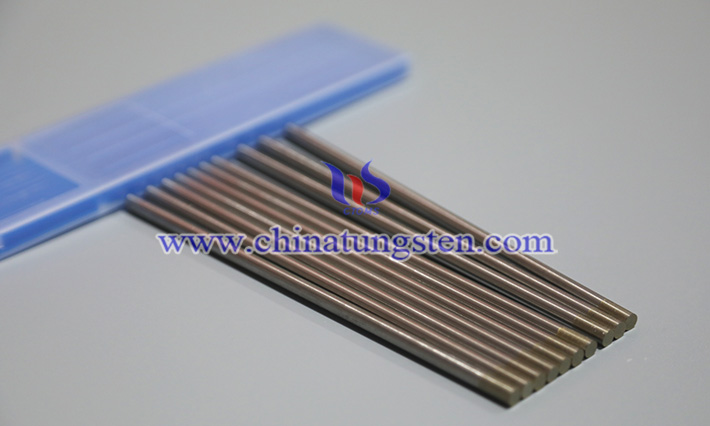

How Strong Is the Burnout Resistance of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:37

During high-temperature, high-energy arc welding, the electrode tip is subjected to multiple stresses, including intense thermal shock, electrochemical reactions, and metal evaporation. These stresses can cause tip burnout and shape degradation, ultimately impacting weld quality and production efficiency.

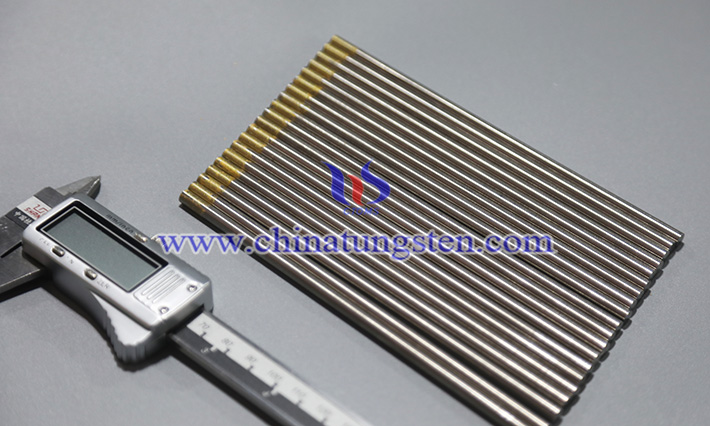

How Is the Anti-Pollution Ability of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:35

In high-precision welding processes such as tungsten inert gas welding (TIG) and plasma welding, the cleanliness and anti-contamination ability of the electrode has a direct impact on the arc quality, weld consistency and equipment stability.

What Is the Thermal Conductivity of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:33

In the welding process, the electrode not only bears the functions of arc guidance and electron emission, but also is the key medium for heat transfer. Good thermal conductivity is crucial for electrode life, welding stability and tip temperature control.

What Is the Conductivity of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:30

In TIG (Tungsten Inert Gas Arc Welding), plasma arc welding and some electronic discharge machining (EDM), the conductivity of the electrode is directly related to arc stability, energy transfer efficiency and welding quality.

How Long Is the Service Life of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:28

In welding, electrodes are the core material for establishing the arc, conducting energy, and forming the weld pool.

What Is the Arc Starting Performance of Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:25

In modern welding processes, especially in high-precision applications like TIG (gas tungsten arc welding) and plasma welding, an electrode's arc starting performance is a crucial parameter for evaluating its quality. Arc starting performance directly impacts the smoothness of the welding operation, the quality of the weld's initial formation, and the stable operation of automated welding systems.

What Is the Electron Emission Capability of Lanthanum Tungsten Electrodes at High Temperature?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:23

In welding processes, especially those requiring a stable, high-temperature arc, such as argon arc welding (TIG) and plasma arc welding, the electron emission capability of the electrode plays a central role in the efficiency and quality of the welding process.

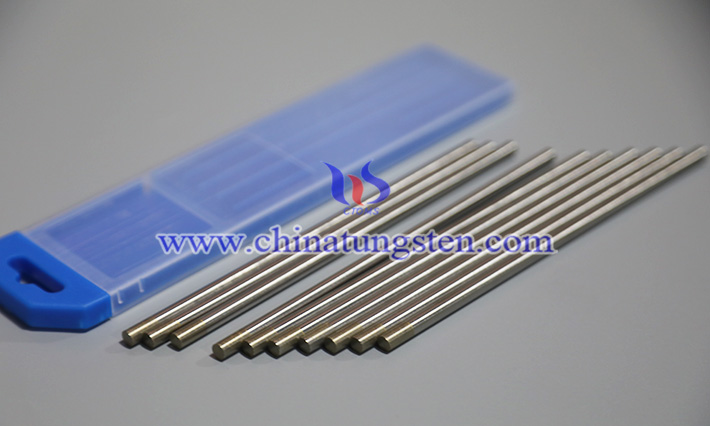

What Are the Advantages of Lanthanum Tungsten Electrodes Compared with Pure Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:20

In high-precision welding techniques like tungsten inert gas welding (TIG), electrodes, as core components for arc generation and energy conduction, play a decisive role in welding performance. Among the many tungsten-based materials, pure tungsten has long been widely used, playing a particularly important role in early welding processes.

sales@chinatungsten.com

sales@chinatungsten.com