What Is the Thermal Conductivity of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:33

In the welding process, the electrode not only bears the functions of arc guidance and electron emission, but also is the key medium for heat transfer. Good thermal conductivity is crucial for electrode life, welding stability and tip temperature control.

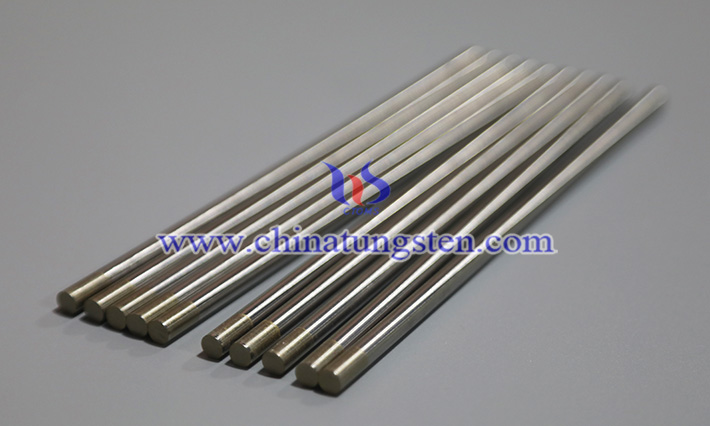

As one of the most widely used rare earth doped tungsten electrodes, lanthanum tungsten electrode has good electron emission ability, and its thermal conductivity is also one of the core factors affecting its overall welding performance.

1. Tungsten-based structure determines good thermal conductivity

lanthanide electrodes is high-purity tungsten. As we all know, tungsten has the highest melting point of all metals (approximately 3410°C) and excellent thermal conductivity, reaching 173 W/(m·K) at room temperature, making it one of the most efficient metals. This characteristic makes tungsten-based electrodes less susceptible to local overheating when subjected to high-temperature arc heating, facilitating rapid heat diffusion into the electrode, thereby preventing tip melting, deformation, or grain coarsening.

La₂O₃ doped in lanthanide electrodes is generally 1.0%~2.0%, and it is evenly distributed in the tungsten crystal in the microstructure as fine particles. Although the thermal conductivity of rare earth oxides is much lower than that of metallic tungsten, due to its small doping amount, it does not significantly reduce the overall thermal conductivity. On the contrary, these fine particles have the effect of stabilizing the grain boundaries and inhibiting grain growth, which improves the overall thermal management ability of the material in high temperature environments from the perspective of thermal stability.

2. Thermal conductivity uniformity improves welding stability

During welding, the electrode tip is the focus of heat concentration. Excellent thermal conductivity means that heat energy can be quickly transferred to the electrode body, effectively preventing the tip from overheating or producing a molten ball, thereby maintaining a good electrode shape. This is especially important for continuous welding, high current welding or robotic welding systems.

Lanthanide electrodes, with their stable thermal conductivity, can work for a long time at a relatively high current (e.g. 150~250A) without significant ablation or collapse, and are particularly suitable for welding high heat load materials such as stainless steel, carbon steel, and copper alloys. Their heat flux distribution is more uniform, making the arc more stable and the molten pool control more precise, further improving the controllability and consistency of the welding process.

3. Comparison of thermal conductivity with other tungsten electrode materials

Pure tungsten electrode: Although its thermal conductivity is close to that of lanthanum tungsten, it is easy to form coarse grains and oxide layers at high temperatures due to the lack of rare earth particles to stabilize the grain boundaries, and its thermal conductivity uniformity is slightly inferior.

Thoriated tungsten electrode: It has good thermal conductivity and excellent arc starting performance, but it contains radioactive components and its use is limited. Lanthanum tungsten is its environmentally friendly alternative product, which has comparable or even more stable thermal performance.

Zirconium tungsten electrode: suitable for AC aluminum welding, with strong thermal shock resistance, but the overall thermal conductivity is slightly lower and the thermal conductivity uniformity is not as good as that of lanthanum tungsten.

4. Performance in practical applications

Actual production shows that lanthanum tungsten electrodes are not only easy to start arcs under medium and high current welding conditions, but also maintain good tip stability during continuous welding, rarely causing problems such as overheating, ablation, oxidation and delamination. Especially in automated welding or multi-pass welding, the heat dispersion effect brought by its thermal conductivity effectively reduces the frequency of manual adjustment and maintenance cycle, and improves the overall welding efficiency.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com