What Are the Advantages of Lanthanum Tungsten Electrodes Compared with Pure Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:20

In high-precision welding techniques like tungsten inert gas welding (TIG), electrodes, as core components for arc generation and energy conduction, play a decisive role in welding performance. Among the many tungsten-based materials, pure tungsten has long been widely used, playing a particularly important role in early welding processes.

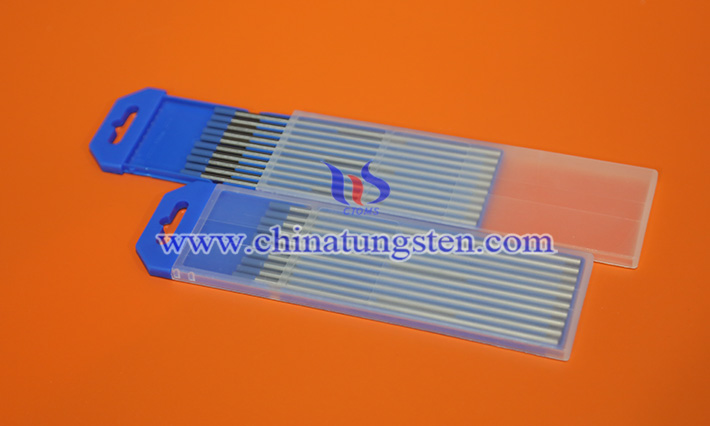

However, with the continuous advancement of welding technology and the increasing demand for welding efficiency, environmental friendliness, and stability, a new rare earth-doped material— lanthanum -tungsten electrodes—is gradually becoming a preferred alternative to pure tungsten. So, what are the specific advantages of these lanthanum- doped products compared to traditional pure tungsten electrodes? The following analysis will examine these advantages from multiple perspectives.

1. Better arc starting performance

The addition of lanthanum oxide (La₂O₃) significantly enhances the material's electron emission capability. This allows doped products to initiate arcs faster, with a focused, stable arc point and low noise, even at the same current. In contrast, pure tungsten, due to its larger electron work function, often starts arcs more slowly, especially at low currents. Lanthanum tungsten products offer significant advantages in welding operations requiring frequent arc initiation or high-precision control.

2. Stronger arc stability

During the welding process, the stability of the arc has a direct impact on the quality of the weld and the feel of the operation. Lanthanum -doped materials can maintain arc stability even under current fluctuations or material thermal expansion conditions due to their excellent thermal electron emission performance and tip shape retention ability. In contrast, pure tungsten is more susceptible to oxidation and ablation under high temperature conditions, resulting in arc jitter, which in turn affects the consistency of the weld.

3. Longer service life

Burnout rate is an important indicator for evaluating the economic performance of electrodes. Electrodes doped with lanthanum have stronger resistance to thermal shock and can effectively delay wear and deformation of the electrode ends, especially in long-term welding at medium and high currents. In comparison, pure tungsten is more prone to problems such as molten balls and tip collapse under continuous high temperatures, requiring frequent repairs and replacements, increasing maintenance costs and production downtime.

4. Wider scope of application

This type of environmentally friendly electrode can be used not only for DC welding (such as carbon steel, stainless steel, copper and other metals), but also for AC welding (such as aluminum, magnesium alloys, etc.) under certain conditions, especially in automated welding equipment and robot welding systems. Pure tungsten is mainly limited to AC aluminum welding, and has higher requirements for current and arc control, and poor flexibility.

5. Environmentally friendly and non-toxic

Although pure tungsten electrodes are non-radioactive, they cannot meet the stringent environmental and safety requirements of some modern industries. Lanthanum tungsten electrodes are non-radioactive and environmentally friendly materials, especially suitable for industries such as aerospace, medical equipment, and food processing equipment, which can help improve the safety level and compliance of corporate products.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com