What Is the Arc Starting Performance of Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:25

In modern welding processes, especially in high-precision applications like TIG (gas tungsten arc welding) and plasma welding, an electrode's arc starting performance is a crucial parameter for evaluating its quality. Arc starting performance directly impacts the smoothness of the welding operation, the quality of the weld's initial formation, and the stable operation of automated welding systems.

Among various electrode materials, lanthanum tungsten electrodes are widely recognized for their excellent arc starting characteristics, demonstrating significant advantages in precision welding and repetitive spot welding.

The so-called "arc starting performance" refers to the ability of the electrode to quickly and stably generate an arc after the current is connected. Excellent arc starting performance means that a bright and concentrated arc can be quickly formed at the moment the welding gun contacts or approaches the workpiece, avoiding problems such as ignition difficulty, arc point drift, arc intermittent or metal splashing. Lanthanum tungsten electrodes perform well in this regard with their low arc starting voltage and high electron emission efficiency.

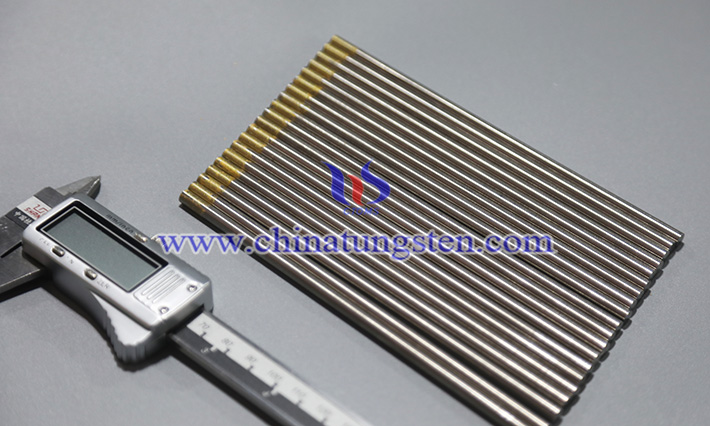

The core advantage of this product lies in its unique material composition. It is based on high-purity tungsten doped with 1.0% to 2.0% lanthanum oxide (La₂O₃). Lanthanum oxide is a high -quality rare earth additive that significantly reduces the electron work function, making it easier for thermal electrons to be emitted from the electrode surface. At high temperatures, this enhanced electron emission capability directly translates into faster arc ignition. Compared to traditional pure tungsten electrodes, the arc starting voltage can be reduced by 10% to 30%, allowing for successful arc initiation even at extremely low currents (e.g., 5-10 amperes).

More importantly, this efficient arc starting capability does not come at the expense of electrode life. Lanthanum doping stabilizes the material's crystal structure, enhancing its resistance to heat and ablation. This allows the electrode to maintain its tip shape even during frequent arc starting and long periods of operation, further ensuring arc reproducibility and consistency. This is particularly critical for processes such as automatic welding, pulse welding, and high-frequency spot welding, which require extremely high arc starting frequencies.

In practical applications, users generally report that this type of product has "fast arc starting", "soft arc starting" and "no arc jumping", especially when welding metals such as stainless steel, carbon steel, copper, and nickel alloys, there is no need to frequently adjust the current to achieve stable arc starting. For manual welders, this smooth arc starting experience also significantly improves operating comfort and welding efficiency. In the automation system, the stability of arc starting performance is directly related to the equipment beat, weld consistency and pass rate.

It should be pointed out that factors such as the sharpening quality of the electrode, the type of power supply (such as high-frequency arc starting or contact arc starting), and the flow rate of shielding gas will also affect the arc starting effect. However, even under suboptimal conditions, lanthanum tungsten electrodes can still show good starting performance, which is one of the important reasons why they are preferred by many welding engineers.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com