Two Common Tungsten Carbide Cutting Tool Cracks

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 November 2014 19:10

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Insert Advantages

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 November 2014 19:03

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Finesse Drop Shot Weights

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 November 2014 08:48

Tungsten finesse drop shot weights are cylindrical with a line guide through their center. It is used as an alternative for Carolina rigging, the weight's profile lets them easily pass through heavy cover and over rocks. The Weights are pegged at a fixed position on the line using specialty stops.

Why Tungsten?

Lead is dead. Lure companies are facing the eventuality of lead bans throughout Canada and the United States. Some states, such as New York, have already banned the use of lead fishing weights in recreational fishing. More lead bans are certain to come.

Tungsten finesse drop shot weights, the most technologically advanced weight available today, provide a more environmentally friendly alternative to lead. Comprised of tungsten, the second hardest substance next to diamonds, tungsten finesse drop shot weights do not add pollutants to water, our most precious resource.

Tungsten finesse drop shot weights which made of tungsten are 25 percent smaller, much more sensitive and emit twice the sound of lead. Their sensitivity gives you the ability to better define under water structure.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

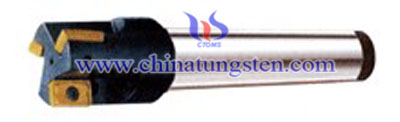

Tungsten Carbide Double Positive Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 18:08

Tungsten carbide double positive milling cutter uses positive inserts held in positive pockets. This is to provide the proper clearance for cutting. Double positive cutter geometry provides for low force cutting, but the inserts contact the workpiece at their weakest point, the cutting edge. In positive rake milling, the cutting forces tend to lift the workpiece or pull the cutter into the work. The greatest advantage of double positive milling is free cutting. Less force is exerted against the workpiece, so less power is required.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Double Negative Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 17:49

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Milling Cutter Milling Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 17:28

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Cutting Tool’s Productivity Advantages

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:52

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable End Mill’s Cost Advantage

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:50

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

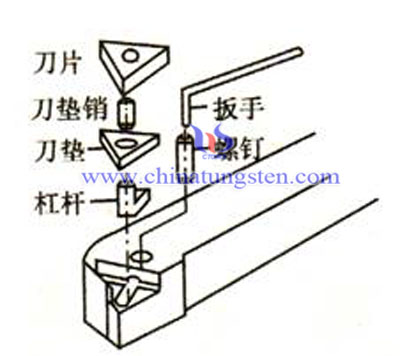

Tungsten Carbide Indexable Turning Tool Lever-type Clamping Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:48

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Turning Tool Eccentric Clamping Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:46

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com