Tungsten Carbide Indexable Inserts Precision Choosing

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:19

The national standard GB/T2076 – 1987 has stipulated twelve grades of precision towards tungsten carbide indexable inserts, which include A, F, C, H, E, G, J, K, L, M, N, u and so on.

G, M, u grades are normally adopted in turning machining, among which, G grade is of the highest precision, and M grade takes the second place, while U grade of the lowest precision. Obviously, during high precision machining, low precision blade can not be used, or it will affect the machining precision and quality of workpieces. Therefore, the precision of tungsten carbide indexable inserts should be chosen according to the precision requirements of the workpieces being processed. Principles below should be followed during the choosing.

I. Blades of G grade should be adopted during the finish machining and semi-finish machining of non ferrous metal materials and in the finish machining of quenched steel.

II. Blades of M grade should be adopted during finish, semi-finish, rough, and heavy cut machining except the two cases above.

III. Blades of u grade can also be adopted in the rough and heavy cut machining.

IV. The precision of indexable inserts used in automatic production lines should be higher than that in the common machining.

V. If there are tool setting gauges, it can be not so strict with the blade precision choosing.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Round Drop Shot Weights

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 09:27

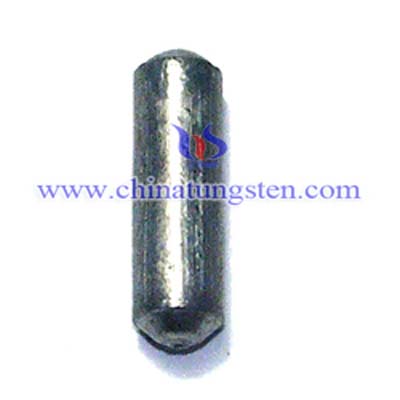

Tungsten round drop shot weights are always in demand on the tournament trail when anglers are faced with ever changing conditions. Each angler knows with dropshotting, extra sensitivity is what it takes to put more fish in the boat. With tungsten round drop shot weights you will feel any and all bottom composition encountered along the way.

Tungsten round drop shot weights feature a swivel line clip for a secure, twist free operation to ensure a proper presentation. All weights have a strong bond between the swivel and weight.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Indexable Drill Bit Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 13 November 2014 17:17

Tungsten carbide indexable drill bit, also called short-hole drill or U drill, is a kind of high-efficiency drilling tool. In recent years, it has been widely used in various kinds of numerically-controlled machining tools, machining centers etc. This kind of drill bit has two indexable inserts installed asymmetrically, forming inner edge and outer edge which are responsible for the machining of internal holes and external holes respectively. When the hole diameter is relatively large, more blades can be installed.

Tungsten carbide indexable drill bit is suitable for high-speed cutting and has high machining quality and good chip removal property. It can be classified into six categories according to its blade shapes, chip removal groove shapes, structure, machining characteristics and so on.

I. Being classified into quadrangle, convex trilateral, rhombus, hexagon drill bit etc. according to blade shapes.

II. Being classified into straight flute drill bit and spiral flute drill bit according to the chip removal grooves.

III. Being classified into cylinder shank drill bit and morse taper shank drill bit according to different drill bit shank shapes.

IV. Being classified into solid, modular and split type drill bit according to the structure.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide End Mill’s Advantages in Thread Machining

- Details

- Category: Tungsten Information

- Published on Thursday, 13 November 2014 17:14

Tungsten carbide end mill is a kind of cutting tool used in thread machining. It was firstly popular in occident, and later, with the development of numerically-controlled machine tools in China, it is also gradually accepted by users in China.

The traditional method for thread machining is normally done by using thread turning tools or screw taps, but now the numerically-controlled machining technology has made it possible to do thread machining with more advanced method, i.e. numerical control milling. Compared with traditional method of thread machining, tungsten carbide end mill machining is of greater advantages in machining precision, machining efficiency, etc. In addition, it is free from the limitation of thread structure and the direction of turning, and thus can be used in the threading of the internal and external threads of different kinds of turning directions.

For those threads that allow no tool withdrawal grooves, it is difficult to do machining with traditional turning method, like using screw taps or threading dies, but easy with numerical control milling. What is more, the duration of tungsten carbide end mill is over ten times larger than screw taps. Also, it is quite convenient to do adjustment towards tread diameter size if an end mill is used in the numerical control milling.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Reins Tungsten Drop Shot Weights

- Details

- Category: Tungsten Information

- Published on Thursday, 13 November 2014 09:07

Reins tungsten drop shot weights do everything they are supposed to do. Reins tungsten drop shot sinkers gives anglers an advantage because it is denser than lead sinkers also meaning that it is more sensitive. These tungsten sinkers are also smaller than traditional lead and make more noise when drug across the bottom.

The unique reins tungsten drop shot weights design makes it easier to pull thru rocks, weeds, or brush with fewer hang ups. Reins down shot sinkers are made up of 95% tungsten and 5% nickel alloy making them 1.8 times as dense as lead and environmentally safe. The dense tungsten material allows you to feel every pebble along the bottom making it easier to tell a strike from a nibble.

Anglers who have always been on the leading edge of environmental activism and care choose Chinatungten Online to provide them a safe alternative to lead fishing weights that contains superior fishing attributes, making the terminal tackle choice that much easier in a time of change. Be the angler with the most technologically advanced fishing tackle in the boat with tungsten dropshot weights of Chinatungsten Online as a part of your terminal tackle.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Two Common Tungsten Carbide Cutting Tool Cracks

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 November 2014 19:10

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Insert Advantages

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 November 2014 19:03

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Finesse Drop Shot Weights

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 November 2014 08:48

Tungsten finesse drop shot weights are cylindrical with a line guide through their center. It is used as an alternative for Carolina rigging, the weight's profile lets them easily pass through heavy cover and over rocks. The Weights are pegged at a fixed position on the line using specialty stops.

Why Tungsten?

Lead is dead. Lure companies are facing the eventuality of lead bans throughout Canada and the United States. Some states, such as New York, have already banned the use of lead fishing weights in recreational fishing. More lead bans are certain to come.

Tungsten finesse drop shot weights, the most technologically advanced weight available today, provide a more environmentally friendly alternative to lead. Comprised of tungsten, the second hardest substance next to diamonds, tungsten finesse drop shot weights do not add pollutants to water, our most precious resource.

Tungsten finesse drop shot weights which made of tungsten are 25 percent smaller, much more sensitive and emit twice the sound of lead. Their sensitivity gives you the ability to better define under water structure.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Double Positive Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 18:08

Tungsten carbide double positive milling cutter uses positive inserts held in positive pockets. This is to provide the proper clearance for cutting. Double positive cutter geometry provides for low force cutting, but the inserts contact the workpiece at their weakest point, the cutting edge. In positive rake milling, the cutting forces tend to lift the workpiece or pull the cutter into the work. The greatest advantage of double positive milling is free cutting. Less force is exerted against the workpiece, so less power is required.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Double Negative Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 17:49

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com