Tungsten Carbide Ball Material Production - Forming Agent

- Details

- Category: Tungsten Information

- Published on Thursday, 25 December 2014 10:01

Paraffin wax and rubber are most widely used in the tungsten carbide ball material production process of forming agent, but because of poor formability paraffin and tungsten carbide ball after a serious increase carbon rubber sintering, people are trying to find a new shape agent to replace the two polymers, hopes that the new wax forming agent both "clean" and rubber excellent formability characteristics, which can improve the tungsten carbide ball hardness and toughness .

Recently, the development of new carbide-forming agents there are two points: first, the "class paraffin" type, this forming agent to maintain the advantages of paraffin and improve its formability on this basis, so that it can improve the tungsten carbide ball properties, such as: the development of a low-melting wax, paraffin wax modification, paraffin wax and beeswax, ozokerite and polymer combination and the like. The second is "rubber" type, the purpose of this is to reduce its forming agent increases the amount of carbon on the basis of merit to keep the rubber, thus ensuring tungsten carbide ball hardness and toughness, mainly PVA, PS, SBS, SBP, SIS and so on.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Types

- Details

- Category: Tungsten Information

- Published on Thursday, 25 December 2014 09:58

Tungsten carbide ball has high hardness, wear resistance, corrosion resistance, can replace all the steel ball products in harsh environment,. According carbide components, tungsten carbide ball can be divided into five categories:

1. Tungsten carbide balls have most varieties, the largest output, and the most widely used.

2. Titanium carbide ball including TIC-Mo-Ni, TIC-WC-TaC (NbC) -Mo-Ni series. They have high hardness, is mainly used for finishing of steel and super finishing.

3. The coated cemented carbide ball which is deposited a layer of titanium carbide, titanium nitride, or a composite of both the oxide and the like on the first type of carbide blade surface.

4. Steel base carbide ball is made of steel or tungsten carbide chin as hard phase, which is characterized by heat treatment can be carried out, in the annealed condition, can be cutting, easy preparation various shapes of complex products.

5. Other carbide ball including chromium carbide based cemented carbide ball, carbo-nitride carbide ball, Carbonation Chin alumina carbide ball, etc., they have different characteristics, and is under development.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

History of Tungsten Heavy Metal

- Details

- Category: Tungsten Information

- Published on Thursday, 25 December 2014 09:30

In 1781, Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite (at the time named tungsten). Scheele and Torbern Bergman suggested that it might be possible to obtain a new metal by reducing this acid. In 1783, José and Fausto Elhuyar found an acid made from wolframite that was identical to tungstic acid. Later that year, in Spain, the brothers succeeded in isolating tungsten by reduction of this acid with charcoal, and they are credited with the discovery of the element.

In World War II, tungsten played a significant role in background political dealings. Portugal, as the main European source of the element, was put under pressure from both sides, because of its deposits of wolframite ore at Panasqueira. Tungsten's resistance to high temperatures and its strengthening of alloys made it an important raw material for the arms industry.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

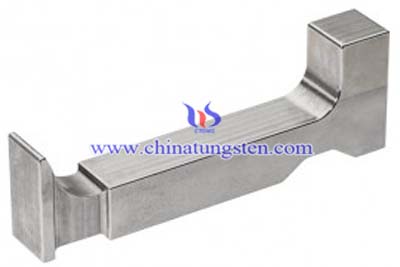

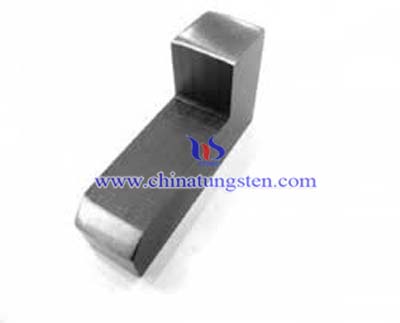

Applications for Tungsten Bucking Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 December 2014 08:53

Bucking bar is used to form bucktails on rivets. And come in many different shapes and sizes. Tungsten bucking bar ,tungsten bar is normally made from an alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet to be driven.

Tungsten bar is used on the backside of a metal rivet to counter the force of the hammering on the other side. They also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Properties of Tungsten Bucking Bar-3

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 December 2014 09:02

Some notable features of tungsten bucking bar are:

1. Excellent durability, robust construction and supreme finish.

2. The bars are made using tungsten alloy which has very high density.

3. All the working bars have well rounded edges and smooth faces.

4. They are ideal for applications that involve vibration damping.

5. The tungsten alloys are mainly composed of 95% tungsten.

6. The bars are designed with a 15 degree angle on one side.

7. Tungsten barscan also be manufactured to match your particular requirements.

8. These bars are specifically useful for bucking rivets.

9. The bars may also be designed with a spacer for low-recoil impact absorption.

10. The bars are manufactured using advanced state-of-the-art processes using high quality certified materials.

Tungsten bucking bar is used to manufacture a wide range of cutting tools for various industries. Apart from riveting operations, these bars are also essential when building aircrafts.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Properties of Tungsten Bucking Bar-2

- Details

- Category: Tungsten Information

- Published on Friday, 19 December 2014 09:30

In situations where working space is limited, tungsten bucking bar is the ideal option. These bars are twice as heavy as the conventional ones made of steel. This material allows you to create smaller bars that can fit perfectly in smaller locations. Although they may have a smaller size, their weight and mass is sufficient for the manufacture of high quality rivets. Apart from the small size for big density, they increase operator comfort by minimizing vibration.

Although these bars may cost substantially more than steel bars, they are worth every penny spent. The experience they offer is simply incomparable. A single tungsten bucking bar can replace several other bars made of steel. These bars are specifically polished on all surfaces to allow bucking on any surface of the bar. Radiused corners prevent any damage to materials.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Properties of Tungsten Bucking Bar-1

- Details

- Category: Tungsten Information

- Published on Thursday, 18 December 2014 09:30

A bucking bar is a tool that is placed on a work surface or the backside of a metal rivet to provide a cushioning counter in order to hammer rivets on the opposite side. It can also be used in operations that require impact fasteners. This includes applications involving tool heads and handle parts that have low recoil absorbing space. The bar size and weight usually depends on the alloy used and the rivet size required.

In everyday use, bucking bars undergo considerable stress. The bars are meant to withstand the impact when rivet guns deliver their impulsive blow. If the supporting metal alloy is rather soft, the bucking bar will quickly wear out and the necessary assembly support will not be achieved. On the flip side, if the metal alloy is very hard and brittle, the bucking bar will soon get fractured. Striking a balance between the tendency to crack and overall hardness is vital for success.

Recent research results indicate that bucking bars made of tungsten provide extra safety for operators through vibration reduction. Operators also get less fatigued and their chances of injury are significantly reduced. The density of tungsten is a reliable property that makes it ideal for future designs of bucking bars. Most bucking bar designs contain 90% tungsten. Deburred edges and polished working surfaces ensure trouble-free use.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Bucking Bar -- Why Use Tungsten?

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 December 2014 09:04

Many companies use steel in the manufacture of their bucking bars, but often this material does not sufficiently absorb the force or deaden the vibration and there is a still a risk to the user.

Tungsten alloy can be used in the manufacture of either the entire bucking bar or just the impact face, and is a much safer alternative than other materials. As tungsten is a very dense metal, a larger mass can be incorporated into a smaller area. The resultant extra weight is pivotal in decreasing the vibration felt by the worker.

Using tungsten bucking bars has been shown to visibly reduce the effects of vibration white finger, and consequently improves efficiency in the workplace. Studies have indicated that using Wolfmet can save workers up to three seconds per rivet.

Tungsten alloy can also be used for other tooling applications such as boring bars for machine tools and grinding quills.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Bucking Bars

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 December 2014 09:03

Tungsten bucking bars are included in powerful tools such as riveting guns in order to reduce vibration.

Employees using this equipment can suffer from industrial diseases such as vibration white finger and carpal tunnel syndrome. These conditions affect the bones, muscles and nerves in the hands, potentially leaving staff unable to work.

Therefore, these bucking bars can play a vital role in maintaining staff wellbeing, as well as preventing your company from having to deal with potentially costly compensation claims from injured workers.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

What is Bucking Bar?

- Details

- Category: Tungsten Information

- Published on Monday, 15 December 2014 09:34

Bucking bar is a work tool received behind work surfaces to provide a backing member in applying impact fasteners and including intermitted toolhead and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear.

Bucking bars are used on the backside of a metal rivet to counter the force of the hammering on the other side. They also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Bucking bars used to form bucktails on rivets. And come in many different shapes and sizes. They are normally made from an alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet to be driven.

The size and weight of the bar depend on the size and alloy of the rivet to be driven. Under certain circumstances, and for specific rivet installations, specially designed bucking bars are manufactured locally.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com