Properties of Tungsten Bucking Bar-2

- Details

- Category: Tungsten Information

- Published on Friday, 19 December 2014 09:30

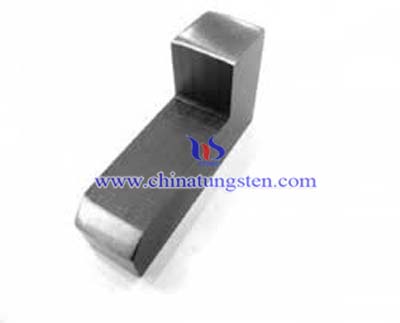

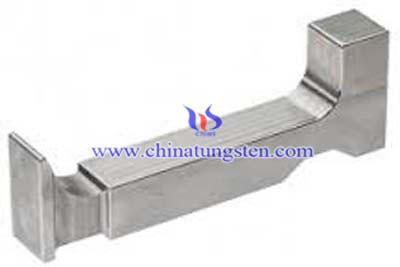

In situations where working space is limited, tungsten bucking bar is the ideal option. These bars are twice as heavy as the conventional ones made of steel. This material allows you to create smaller bars that can fit perfectly in smaller locations. Although they may have a smaller size, their weight and mass is sufficient for the manufacture of high quality rivets. Apart from the small size for big density, they increase operator comfort by minimizing vibration.

Although these bars may cost substantially more than steel bars, they are worth every penny spent. The experience they offer is simply incomparable. A single tungsten bucking bar can replace several other bars made of steel. These bars are specifically polished on all surfaces to allow bucking on any surface of the bar. Radiused corners prevent any damage to materials.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Properties of Tungsten Bucking Bar-1

- Details

- Category: Tungsten Information

- Published on Thursday, 18 December 2014 09:30

A bucking bar is a tool that is placed on a work surface or the backside of a metal rivet to provide a cushioning counter in order to hammer rivets on the opposite side. It can also be used in operations that require impact fasteners. This includes applications involving tool heads and handle parts that have low recoil absorbing space. The bar size and weight usually depends on the alloy used and the rivet size required.

In everyday use, bucking bars undergo considerable stress. The bars are meant to withstand the impact when rivet guns deliver their impulsive blow. If the supporting metal alloy is rather soft, the bucking bar will quickly wear out and the necessary assembly support will not be achieved. On the flip side, if the metal alloy is very hard and brittle, the bucking bar will soon get fractured. Striking a balance between the tendency to crack and overall hardness is vital for success.

Recent research results indicate that bucking bars made of tungsten provide extra safety for operators through vibration reduction. Operators also get less fatigued and their chances of injury are significantly reduced. The density of tungsten is a reliable property that makes it ideal for future designs of bucking bars. Most bucking bar designs contain 90% tungsten. Deburred edges and polished working surfaces ensure trouble-free use.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Bucking Bar -- Why Use Tungsten?

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 December 2014 09:04

Many companies use steel in the manufacture of their bucking bars, but often this material does not sufficiently absorb the force or deaden the vibration and there is a still a risk to the user.

Tungsten alloy can be used in the manufacture of either the entire bucking bar or just the impact face, and is a much safer alternative than other materials. As tungsten is a very dense metal, a larger mass can be incorporated into a smaller area. The resultant extra weight is pivotal in decreasing the vibration felt by the worker.

Using tungsten bucking bars has been shown to visibly reduce the effects of vibration white finger, and consequently improves efficiency in the workplace. Studies have indicated that using Wolfmet can save workers up to three seconds per rivet.

Tungsten alloy can also be used for other tooling applications such as boring bars for machine tools and grinding quills.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Bucking Bars

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 December 2014 09:03

Tungsten bucking bars are included in powerful tools such as riveting guns in order to reduce vibration.

Employees using this equipment can suffer from industrial diseases such as vibration white finger and carpal tunnel syndrome. These conditions affect the bones, muscles and nerves in the hands, potentially leaving staff unable to work.

Therefore, these bucking bars can play a vital role in maintaining staff wellbeing, as well as preventing your company from having to deal with potentially costly compensation claims from injured workers.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

What is Bucking Bar?

- Details

- Category: Tungsten Information

- Published on Monday, 15 December 2014 09:34

Bucking bar is a work tool received behind work surfaces to provide a backing member in applying impact fasteners and including intermitted toolhead and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear.

Bucking bars are used on the backside of a metal rivet to counter the force of the hammering on the other side. They also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Bucking bars used to form bucktails on rivets. And come in many different shapes and sizes. They are normally made from an alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet to be driven.

The size and weight of the bar depend on the size and alloy of the rivet to be driven. Under certain circumstances, and for specific rivet installations, specially designed bucking bars are manufactured locally.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- The Grommet Trick

- Details

- Category: Tungsten Information

- Published on Friday, 12 December 2014 08:59

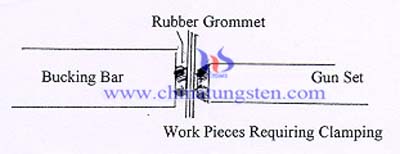

A hard rubber grommet is placed over the buck tail of the rivet. The grommet should be slightly thicker than the length of the buck tail. As the bucking bar is compressed against the tail during riveting the rubber squeezes the components together until the rivet expands enough to secure them permanently. This is a useful technique when clecoes or clamps are impractical.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Rivet Sets for Skin Riveting

- Details

- Category: Tungsten Information

- Published on Thursday, 11 December 2014 08:48

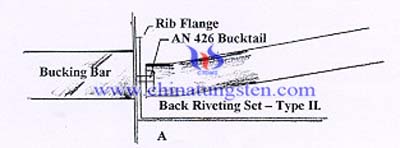

If possible, skins should be back riveted. This process provides cosmetic (and some structural) protection to the outer skin. Some locations will permit access for use of the spring loaded (type I) back riveting set. On others, such as wing ribs, a special long back set having an angled face is used to back set rivets. In either case, a partner uses a polished, 3" diameter back riveting bar (plate) to buck rivet heads from the outer side of the skin.

The Swivel flush set mentioned above is a must when selecting aircraft riveting tools. Unlike conventional sets, the swivel set will maintain flush contact with the surface being riveted, despite small variations from vertical in gun position. This helps to prevent 'smiles' in the surface caused by a slightly cocked gun set. Also, the rubber outer boot around the set allows the operator's free hand to secure the face of the set to the work surface - this prevents smiles and it also prevents the gun from accidentally traveling off position. If the skin cannot be back riveted, normal riveting with a swivel set will help to maintain a similar quality.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Riveting with a Partner

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 December 2014 09:17

There are places on RVs which cannot easily be riveted by one person. Main wing skins are a good example. This becomes a two-person operation, with one bucking and one riveting. The principles of good riveting are exactly the same, the only variable introduced is the co-ordination of two workers (and the advantage of two extra hands). As the partners cannot see what the other is doing, a system of verbal signals is used to direct operations. One which works is:

1.The riveter inserts a rivet into the prepared hole; positions the gun for setting and calls, "ready".

2.The bucker positions the bucking bar over the rivet tail and, if its position is correct, will call, "go". If the rivet is in an awkward position the bucker may want to slide the rivet out and in to determine its point of balance (as above). He/she will call, "out" while pushing the rivet out toward the riveter until the bar comes to rest on the aluminium. To reposition the rivet for setting the bucker will call, "in".

3.The riveter will firmly push the gun against the work and may also use the other hand to press the set against the work, if it is of the flush swivel type (see below). As the rivet re-seats this force pushes the bucking bar back into position. If the bucker is satisfied with the orientation of the bucking bar the call "go" is given.

4.The riveter then drives the rivet for a time determined by experience or a test piece. This interval is usually less than a second and is best remembered as a musical phrase, such as a drum roll.

5.The bucker will check the tail for quality and will call "next" if all is well and the pair can move on the the next rivet or "again" if the rivet needs a bit more driving or "remove" if the rivet is not acceptable. The riveter marks the rivet for later removal with a felt pen.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Back Riveting -- Solution

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 December 2014 09:03

1.Using shims, level the back riveting plate on the table.

2.Using a drill press, drill a half inch hole almost through a 4" x 4" x 2" piece of hardwood.

3.Mount a straight universal head rivet set in riveting gun.

4.Use Vaseline to push the end of the set into the hole in the hardwood.

5.Place the hardwood on the levelled surface plate so that the gun is supported vertically.

6.Secure a round bubble level vial to the butt of the rivet gun with RTV or a silicone adhesive.

7.Make sure the vial is positioned so that the bubble is in the centre.

8.Secure the assembly so that it cures in that position overnight.

This will aid in setting perfectly aligned rivets provided

a.The back riveting plate is levelled prior to use;

b.The gun is held with the bubble in the centre while riveting.

Note: It pays to periodically recheck calibration using the wood block and straight rivet set. The straight set is only used during calibration. The back riveting set is reinstalled for actual riveting.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Back Riveting -2

- Details

- Category: Tungsten Information

- Published on Monday, 08 December 2014 09:24

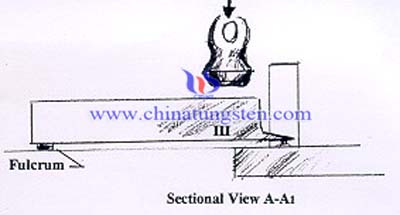

Type II

Type III

If the builder is working alone, sometimes it is difficult to judge when the backriveting set/gun is square to the surface being joined.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com