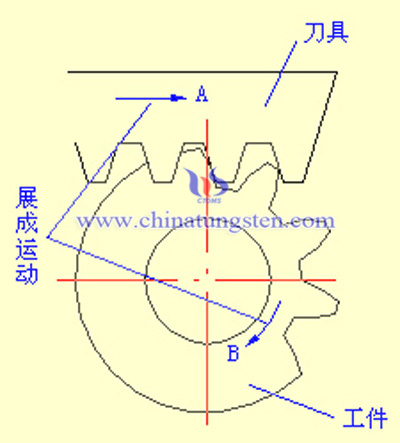

Tungsten Carbide Cutting Tool Machining Methods

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 November 2014 18:27

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

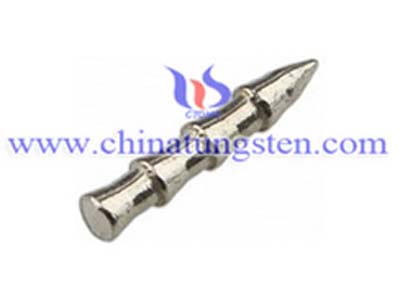

Tungsten Pagoda Nail Sinkers

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 November 2014 08:47

Tungsten pagoda nail sinkers, also called tungsten pagoda nail weights offer the enhanced performance of tungsten. You can not only weight down those soft plastics with small tungsten pagoda nail weights that stay in place but achieving the right presentation you desire thanks to the careful barbs.

The higher density of tungsten allows them to be far smaller than comparable lead, brass or steel weights, and the exaggerated ribs of the pagoda nail weights also ensure they stay firmly in place inside your favorite soft plastic baits. Available in a variety of sizes, tungsten pagoda nail weights are also 100% environmentally friendly, helping to protect our fisheries for future generations.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Boring Cutter Types

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 November 2014 18:47

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Boring Cutter Installation

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 November 2014 18:45

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Reins Tungsten Nail Sinkers

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 November 2014 08:56

When it comes to weighting a lure, there is no other choice but reins tungsten nail sinkers to get the job done! In doing so, you can easily get the bait down to the "perfect" level where it has a chance to be consumed in one gulp! With its popular barbs, reins tungsten nail sinkers are sure to stay firmly in place throughout the cast.

Reins tungsten nail sinkers help you fine tune your baits, they are used on soft plastics or on wood plugs. Commonly, rein tungsten nail sinkers can be used in the nose of a worm to give you just the right action, or maybe you need to balance that frog or plus to swim just right.

Why Tungsten

Tungsten, with the density rages from 16.5 to 18.5, is widely used by more and more manufacturer in making reins nail sinkers. Reins tungsten nail sinkers have better penetration power compared with other materials made nail sinkers, such as lead, brass, est. Besides, reins tungsten nail sinkers are environment friendly, which is an important factor nowadays.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Angle End Mill Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 18:23

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Die Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 18:19

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool CVD Coating Technology Development

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 18:17

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

High-Density Heavy Metals for Radiation Shield

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 14:02

Tel.: 86 592 5129696; Fax: 86 592 5129797Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Alloy for Efficient Radiation Protection

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 13:59

Tel.: 86 592 5129696; Fax: 86 592 5129797 Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com