Tungsten Carbide Reamer Problems and Countermeasures (I)

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 18:23

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

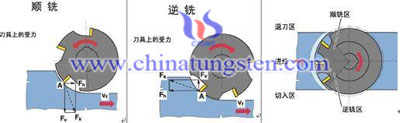

Tungsten Carbide Milling Cutter’s Climb Milling and Up Milling Comparison

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 18:21

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Milling Cutters' Milling Ways

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 18:18

Tungsten Carbide Cutting Tool Coating Technology Introduction

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 18:16

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

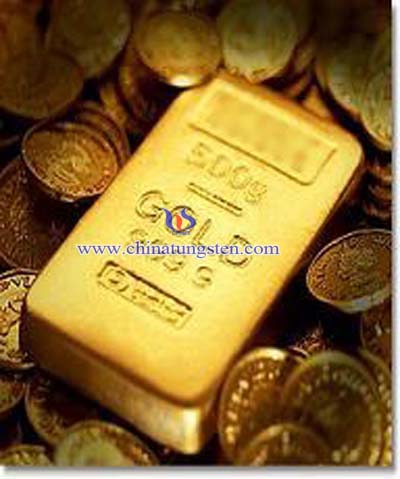

Counterfeit Gold-Plated Tungsten Bar-1

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 08:50

The following article is talking about the story of counterfeit gold-plated tungsten bar, written by unknow person.

In his March 2 column, he told about the news story where an employee at the world’s largest private refinery had discovered a gold-plated 500 gram gold bar received from an unidentified bank. His column included an internet link where readers could themselves view the German television station report.

As is common for his columns, this particular one was picked up by several other websites. This particular column inspired a relatively harsh response from Robert Bradshaw. In an essay Robert wrote that was posted yesterday at http://www.marketoracle.co.uk/Article17820.html, Robert took me to task for repeating the story that China’s central bank last year had received at least four counterfeit gold-plated 400 ounce tungsten bars. Robert seemed concerned that he was perpetuating a myth about a massive number of counterfeit gold-plated 400 ounce tungsten bars that were supposedly manufactured during the 1990′s at the behest of the US government. Allegedly, about half of them were shipped to Fort Knox.

Until today’s column, he have never referred to the rumor of large numbers of counterfeit gold bars supposedly stored at Fort Knox. he is well aware of the details of this rumor but, like Bradshaw, the possibility of the whole story being true is pretty far-fetched. He would need to dig up more hard confirmation of its veracity before discussing it. If such verification were available, I’m sure that this story would be headline news in the mainstream financial press.

The precious metals markets are not transparent. To get the best idea of what is really happening means listening to sources that often cannot be independently double-checked. In his writings, he tries to be careful to listen only to those sources that have developed a track record of reliability. In this manner, he can often discern the truth long before it is publicly disclosed.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

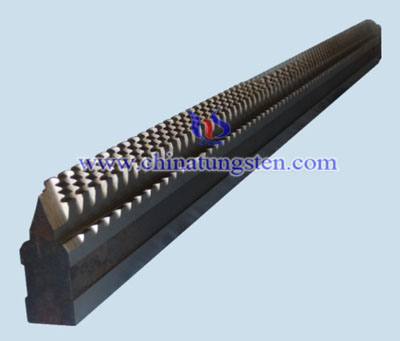

Tungsten Carbide Keyway Broach Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 October 2014 18:01

Tungsten Carbide Gear Shaving Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 October 2014 17:59

Tungsten Carbide Slotting Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 October 2014 17:58

Tungsten Gold Plated Bar Story -- Aliens hunting for gold on Earth? 2

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 October 2014 08:43

“We are at the heart of this global control because of our mineral resources,” he said.

On the first day of the conference, all the speakers agreed that like humans who had the potential to be both good and bad, so too was the population of galactical beings.

Extra-terrestrials were also not dissimilar to politicians, who pushed their own agenda for material gain.

“They came to Earth looking for gold. We are all still obsessed with gold,” he said.

The research, according to Tellinger, showed that the extra-terrestrial “Annunaki” came to Earth around 300,000 years ago to look for gold, and that they were also responsible for cloning their own genetic structures and creating mankind.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Reamer Reaming

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2014 18:52

sales@chinatungsten.com

sales@chinatungsten.com