Tungsten Carbide Extrusion Tap Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 October 2014 17:41

Tungsten Carbide Straight Flute Tap Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 October 2014 17:37

Tungsten Carbide Spiral Pointed Tap Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 October 2014 17:34

Tungsten Carbide Tap Advantages

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 October 2014 17:32

The Differences Between Real and Fake Gold 1

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 October 2014 08:56

It's All About the Physics

All the ways to determine the authenticity of a coin or bar of precious metal are based on differences between physical properties of the valuable metal and the lesser metals used to swindle the buyer. Each metal is an element, meaning it can't be further broken down into another element (without very heavy equipment like a particle accelerator, which is not practical). An element has its own unique density, conductivity, reaction to acids, melting point, conductivity of sound through the metal, etc. A fake gold coin will necessarily have an exterior of gold to help fool the buyer, regardless of the contents of the interior and whether the coin is created from an alloy (mix of metals) or a slug of base metal with a cladding or plating of gold on the outside.

Visual Inspection

The easiest place to start is the visual appearance of each metal. Does the coin look gold in color? Gold has a dull golden shine. Once you've spent time handling gold, this is the first give away. Keep in mind that some coins are 99.99 percent pure gold. Others are designed for circulation and have some copper and silver alloyed with the gold. These coins have a reddish tint. Jewelers use these properties to make many different shades of gold for jewelry.

The color difference is exaggerated in these photos, but it gives an idea of the difference between 99.99% pure gold coins (left) and 90% pure gold coins with an alloy of copper and silver that make the coin harder and able to circulate (right).

Density

The physical characteristics of metals are immutable and this is the counterfeiter's first decision; which metal(s) to use for the fake. Each metal has characteristics like density, malleability, the speed of sound in the metal and so on.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

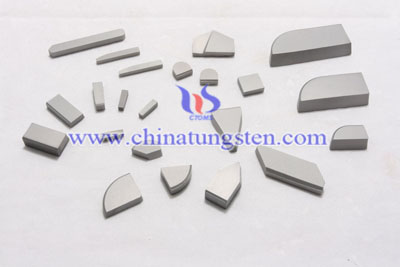

Choosing Brazed Tungsten Carbide Blade and Groove Shape

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2014 17:46

Tungsten Carbide Keyway Milling Cutter and End Mill Differences

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2014 17:43

Tungsten Carbide Indexable Turning Tool Advantages

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2014 17:41

Brazed Tungsten Carbide Turning Tool Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2014 17:31

Tungsten Carbide Treading Turning Tool Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2014 17:28

sales@chinatungsten.com

sales@chinatungsten.com