Tungsten Nail Sinkers

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 13:41

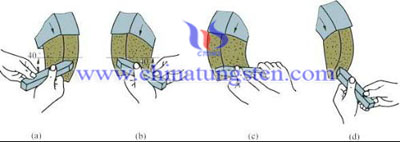

Nowadays, a popular approach to weighting down soft plastics is the advent of small tungsten nail sinkers to add small amounts of weight internally to soft plastic lures.

Tungsten nail sinkers are thin and nail-like weights insert into soft-plastic baits, like jerk baits, sticks or finesse worms. Tungsten nail sinkers can be used to balance rigged jerk bait for a natural-looking fall. Another option is tail-weighting finesse worms for a tail-first, fall that can trigger hits from shy, following fish.

Tungsten nail sinkers are perfect for adding a small amount of weight to your soft plastic lures. An adjustment in weight can make the difference when conditions on the water change or you want to modify your bait's action. Easily clipped down with standard line clippers, tungsten nail sinkers are an ace-up-your-sleeve. The ability to make quick changes helps you stay one step ahead.

Each active tungsten nail sinker comes with three factors: a sharp tip to penetrate any section of the soft plastic lure, a narrow shank profile to minimize damage to the soft plastic lure and a set of conical barbs along the length of the shank to securely fasten the tungsten nail sinkers into the body of your soft plastic lure.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Manufacturers Should Keep an Eye on Tungsten Carbide Cutting Tool Wear

- Details

- Category: Tungsten Information

- Published on Friday, 31 October 2014 18:54

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Turning Tool Sharpening

- Details

- Category: Tungsten Information

- Published on Friday, 31 October 2014 18:49

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Counterfeit Gold-Plated Tungsten-3

- Details

- Category: Tungsten Information

- Published on Friday, 31 October 2014 08:44

He believes these were the only instances where he wrote about possible counterfeit gold-plated tungsten bars before his March 2 column for CoinUpdate.com. Since last October, there has been ample time for either the Chinese central bank or the US bonded warehouses who supplied them with gold bars to have publicly addressed the rumors of counterfeit gold bars. None have done so. This silence could be interpreted two different ways. If the report of counterfeits is possibly true, the parties involved are just hoping that the story dies down. Or if the story is false, the parties involved may not have deemed it important enough to give it more widespread coverage by issuing a refutation.

If even a portion of the stories of counterfeit gold-plated bars turn out to be true, governments, central banks, brokerage firms, and owners of the bonded warehouses would have a strong incentive to hush up the information. In the past decade, a downpour of released unclassified US documents confirm that the US government has lied to the public for a long time about issues related to gold—going all the way back to 1918! So, he has significant suspicions that the US government today is not being honest about gold trading and inventories.

Bradshaw’s column was pretty much accurate when it cited specifics from his column last week. But it seems Bradshaw used the column to discuss the issue that really bothered him—the rumors about counterfeit gold bars at Fort Knox—about which he has never before written. The way Bradshaw wrote his column, more than one reader thought that he might have irresponsibly passed along rumors on this subject as being established fact. While others, not named in Bradshaw’s column, may have done so, he only accept the credit (and occasional blame) for what I have written. When you try to be on the cutting edge of breaking information, sometimes you blow it. He thinks I did it properly this time.

By the way, while he is discussing government deception of the public, he does admit that politicians and bureaucrats are frequently truthful. Despite my suspicious nature, he does believe the testimony before Congress a few months ago by the general counsel for the Federal Reserve. When Scott G. Alvarez made an unqualified statement that all of the gold supposedly stored in Fort Knox was actually there, even though it has not been audited since the 1950s, he bet that’s true. However, Alvarez was not asked and did not volunteer any information as to who holds title to the gold stored at Fort Knox. he has significant suspicions that some of it is owned by other parties as a result of gold swaps, particularly the German central bank.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

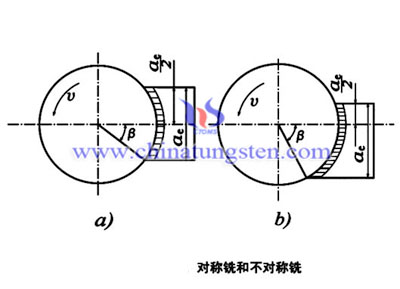

Tungsten Carbide Milling Cutter Milling Types

- Details

- Category: Tungsten Information

- Published on Thursday, 30 October 2014 18:02

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Formed Turning Tool Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 30 October 2014 18:00

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Coating Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 30 October 2014 17:56

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Clip-type Thread Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 30 October 2014 17:53

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Counterfeit Gold-Plated Tungsten Bar-2

- Details

- Category: Tungsten Information

- Published on Thursday, 30 October 2014 08:45

There have been infrequent reports over the decades of genuine gold bars that were drilled and filled with tungsten. He never discussed them because they were isolated small-scale activities. However, the story of large quantities of possible counterfeit large gold bars is a story that, if true, the public would really need to know.

The information about the possible counterfeit gold-plated tungsten bars came to me from sources with a good track record of reliability. Still, when he discussed them last fall, I was careful to indicate that they were rumors.

In his October 19, 2009 column at Numismaster.com, titled “What A Run On Gold Looks Like,” in the middle of the essay, he started one paragraph with, “There is a story now circulating that I have to classify as a rumor.” It goes on to discuss the possibility that some of the gold bars provided on the London exchange by the Bank of England may have been filled with tungsten. He further explained in that column that some of the gold bars held by the US and British governments were probably of lower purity, about 90%, than would be acceptable for delivery on the London market.

In the November 4, 2009 issue of Liberty’s Outlook he mentioned to readers, under the headline titled “Rumor—Counterfeit Gold Bars Discovered In Central Bank Vault,” about the China central bank story. He also listed a website address of a Chinese company offering gold-plated tungsten products that showed a photograph of a small gold bar on the home page of its internet site. He mentioned that if the China central bank story turned out to be true, it would have significant ramifications.

In the December 2, 2009 issue of Liberty’s Outlook, under the headline “Reasons Why Gold And Silver Are Likely To Rise Much Further,” he passed on subsequently received information that there were supposedly four counterfeit bars detected by China’s central bank and that the counterfeits came from bonded warehouses in the US. The discussion uses several qualifiers such as “allegedly” and “could.” At the end of that section he disclosed that reporters trying to cover this issue were sitting on additional damning information because they were unable to obtain sufficient corroborating evidence.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Reamer Problems and Countermeasures (II)

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 18:25

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com