Tungsten Carbide Rotating Nozzle Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 16 October 2014 18:23

Tungsten Carbide Nozzle Introduction

- Details

- Category: Tungsten Information

- Published on Thursday, 16 October 2014 18:19

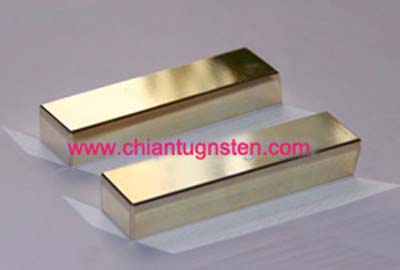

Tungsten Gold Plated Bar Properties

- Details

- Category: Tungsten Information

- Published on Thursday, 16 October 2014 09:00

Some people has the idea that tungsten gold plated bar can be a substitute of gold bar as memento. This is an opinion which has stirred the discussion. The reason should be concluded to the properties of tungsten bar with gold plated.

In theory, the density of tungsten gold plated bar is 19.1g/cm3, which is approximately 70% denser than lead, uranium could be used as material of making fake coin. However, it is weakly radioactive and not as dense as gold, so it does not appear to be a practical method. Even so, it still has the value as souvenir to be remembered.

Tungsten gold plated bar is corrosion resistance. This can be the reason for this bar as memento to memo some important events. For example, engrave the marriage anniversary date, birthday, or Olympic day, or some important festival.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Maximum Profits Achieved by Tungsten Carbide Cutting Tools

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 18:33

Tungsten Carbide Cutting Tool Regrinding

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 18:31

Advantages of Tungsten Carbide Threaded Milling Cutter

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 18:25

Tungsten Carbide Straight Shank Reamer Introduction

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 18:22

Tungsten Carbide V-CUT Knife Precautions for Use

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 18:18

Tungsten Gold Plated Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 October 2014 09:42

Tungsten gold plated bar is bar made of tungsten and plated by gold. They are widely used as substation of gold bar as memento, jewelry and so on.

Tungsten gold plated bar has the properties of tungsten, which are high density, durable, hardness, oxidization resistance, and weak radioactive. What’s more, tungsten gold plated bar is environmental-friendly, which has been a reason for the popularity of people all over the world.

Tungsten gold plated bar has the surface of gold, which is smooth and bright as copper mirror, and able to reflect the images which are next to it. They are gold color, which is attractive and pleasant to eye.

Tungsten gold plated bar can be not only manufactured with gold plated only, but also with letters engraved on it. And the letters can be chosen by customers or engraved according to customers’ drawings.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide V-CUT Knife Common Specifications

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2014 18:01

Tungsten carbide V-CUT knife is mainly made from tungsten carbide, which is also known as tungsten steel. Therefore, this kind of knife is also called solid tungsten steel V-CUT knife. It is a kind of electronic cutting tools commonly used in the production of circuit board, and there are six main product specifications:

No. OD × ID × thickness teeth number angle

I. φ56.3 × φ25 × 2.4, 48 teeth, angle 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

II. φ51.3 × φ25 × 2.4, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

III. φ51.3 × φ25 × 2.0, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

IV. φ39.5 × φ17 × 2.4, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

V. φ32 × φ17.5 × 2.4, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °,

VI. φ28 × φ15 × 2.0, 48 teeth, the angle of 20 °, 25 °, 30 °, 35 °, 40 °, 45 °, 50 °, 55 °, 60 °.

Tungsten carbide V-CUT knife with advantages of high hardness, strength and abrasion resistance as well as long service life can significantly improve productivity.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com