Regeneration Solution of SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 February 2016 16:20

More than 90% of the thermal power plants deal with the flue gas denitrification using SCR which is short for Selective Catalytic Reduction, making SCR process widely use. The cleaning and regeneration of the catalyst is not only one of the effective methods to reduce the running cost of flue gas, but also can reduce the environmental pollution caused by solid waste. This paper introduces a kind of Regeneration Solution of SCR Denitration Catalyst.

More than 90% of the thermal power plants deal with the flue gas denitrification using SCR which is short for Selective Catalytic Reduction, making SCR process widely use. The cleaning and regeneration of the catalyst is not only one of the effective methods to reduce the running cost of flue gas, but also can reduce the environmental pollution caused by solid waste. This paper introduces a kind of Regeneration Solution of SCR Denitration Catalyst.

The components of it are as follows: Penetration enhancer (JFC) takes the 1‰~5wt‰ of total content, surfactant take 1‰~5wt‰, peregal take 0~5wt‰, ammonium metavanadate take 1%~4wt%, ammonium paratungstate take 6%~12wt% and ammonium molybdate take 2~6wt%, distilled water and acid take the remained contents.

The acid is the role of adjusting pH value in range 5~7, can be anyone of citric, oxalic and acetic acid.

The advantages of Regeneration Solution of SCR Denitration Catalyst are as follows:

1. Make-up active ingredients by the time cleaning denitration catalyst, which can significantly improve the activity of deactivation, and recover the activity as high as 90~105%;

2. Nonionic surfactant added in the regeneration solution not only improves the cleaning ability of catalyst, but also cause no damage to the catalyst carrier and other active components;

3. Catalysts after regeneration can be completely normal used making the service life reach more than 95% as the new catalyst.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparation for NOx Series Catalyst with Selective Catalytic Reduction at High Temperature

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 February 2016 16:16

When the temperature of waste gas is higher than 500℃, Vanadium catalyst directly oxidation of NH3is significantly enhanced, resulting in a significant reduction in the removal rate of NOx. Under high temperature, the WO3-TiO2 system has better catalytic activity and high temperature stability compared to the traditional V205-W03/TiA system. A method for preparing WO3-TiO2 catalyst is described in this paper, steps are as follows:

1. Mixing ethanol, tetrabutyl titanate and glacial acetic acid by volume ratio 2:1:1, get solution A;

2. Dissolve ammonium paratungstate in the oxalic acid solution with mass concentration of 5% to obtain solution B, in which the mass ratio of ammonium paratungstate: oxalic acid is 1.6:1;

3. Drop a certain amount of solution B into solution A slowly, in which the quality ratio of ammonium paratungstate and tetrabutyl titanate is 0.029:1~0.11:1, stirring constantly to form a uniform and stable sol;

4. Static settling for 40~60 hours, dry in an oven at the temperature of 50~ 60℃ for 16~30 hours to get a dry gel;

5. Grind the dry gel in a mortar for 30~50 minutes, then calcine in the muffle furnace at 550~650 ℃ for 3~6 hours, get the high temperature SCR catalyst WO3-TiO2 with the active component WO3.

The catalyst in this paper has the advantages like: simple process and low production cost, with high active at the temperature of 450~550℃, higher denitrification rate, long service life, high thermal stability.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Complex Characterization

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 February 2016 15:24

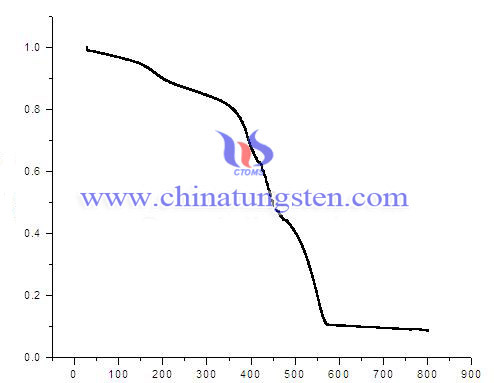

TG (Thermal Gravity Analysis) is a term of thermodynamics, called thermal gravimetric analysis. Its meaning is: The sample in the specified temperature curve (rate), the rate decreases with its weight / ratio analysis. From the curve we can know the weight of sample reducing at certain temperature, and then it shows that the decomposition temperature of the sample at this occurrence (or other chemical reactions) is the most severe. TG Category 1, static method (isothermal): sample at a constant temperature, known as the "constant weight loss." TG Category 2, the dynamic method (temperature method): the sample under constant temperature, known as "TGA curve."

TG (Thermal Gravity Analysis) is a term of thermodynamics, called thermal gravimetric analysis. Its meaning is: The sample in the specified temperature curve (rate), the rate decreases with its weight / ratio analysis. From the curve we can know the weight of sample reducing at certain temperature, and then it shows that the decomposition temperature of the sample at this occurrence (or other chemical reactions) is the most severe. TG Category 1, static method (isothermal): sample at a constant temperature, known as the "constant weight loss." TG Category 2, the dynamic method (temperature method): the sample under constant temperature, known as "TGA curve."

During the inspection process, the first steep, placing synthetic product in a muffle furnace, burning it 3h at 400 ℃ to obtain the tungsten trioxide powder samples of different doping amount of tungsten trioxide, and then getting the results via TG at FIG 50-400 ℃, characterizing it by the percentage change to determine the tungsten trioxide complex. From the TG graph , we can see when the temperature reaches at 350 ℃ , TG curve is approximately straight line, which indicates that synthesis product is lost when the temperature is about 350 ℃ . Weight of the synthetic product constantly decreases with temperature increasing.

Next, the synthesized product was characterized by X-ray powder diffraction analysis, the diffraction peaks can be found in standard synthetic products that were monoclinic phase product coincide, and there are not impurity peaks, which show the composite tungsten oxide does not cause polymorphs variety. In summary, the tungsten trioxide complex becomes into the admixture does not have a change in crystal form molybdenum trioxide.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Low Temperature Hydrothermal Method Preparing Tungsten Trioxide Complex

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 February 2016 15:13

Hydrothermal is the study of geologist simulating the natural mineralization in 19th century. Hydrothermal method is a category of liquid chemical method. Hydrothermal method is a method in a sealed pressure vessel, chemical reaction at high temperature and pressure conditions. Hydrothermal reaction depends on the type of reaction that can be divided into hydrothermal oxidation, hydrothermal reduction, hydrothermal precipitation, hydrothermal synthesis, water, thermal hydrolysis, hydrothermal crystallization. The material is dissolved in an aqueous nutrient medium in the heat, in the form of ions, molecules become into the solution.

Hydrothermal is the study of geologist simulating the natural mineralization in 19th century. Hydrothermal method is a category of liquid chemical method. Hydrothermal method is a method in a sealed pressure vessel, chemical reaction at high temperature and pressure conditions. Hydrothermal reaction depends on the type of reaction that can be divided into hydrothermal oxidation, hydrothermal reduction, hydrothermal precipitation, hydrothermal synthesis, water, thermal hydrolysis, hydrothermal crystallization. The material is dissolved in an aqueous nutrient medium in the heat, in the form of ions, molecules become into the solution.

Single tungsten trioxide material properties in the structure are flaws, they can not meet all the needs of practical application, in order to improve the performance of tungsten trioxide to meet the needs of more areas, we use the following method to prepare tungsten trioxide, which doping molybdenum trioxide, complexes were characterized on the structure and composition to improve the value of the actual use of composite tungsten trioxide.

Incorporating trioxide molar percentage of 0%, 1%, 5%, 8%, 10%, 12% ratio, a certain quality and 1.000g of sodium molybdate was dubbed to sodium tungstate solution, mixing them well. The above solution was dropped to 2ml hydrochloric acid, stirring 0.5h, transferring to a stainless steel autoclave, containing it at 100 ℃ about 24h. Drying it in forced air oven 6-7h, then placing it in a muffle furnace , burning it 400 ℃ 3h, tungsten trioxide is complex at last.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Brick for Performance Prop

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 February 2016 14:43

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Brick for Gold Detection

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 February 2016 14:41

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Valve Ball Advantages (2/2)

- Details

- Category: Tungsten Information

- Published on Monday, 15 February 2016 17:24

Continued from the preceding page, the advantages of tungsten carbide ball valve are given as follow:

5. It has bidirectional sealing property, which make the process more stable;

6. When fully open or fully closed, the ball and seat sealing surface and the medium is completely isolated state, which makes high-speed flow of the media is not prolonged contact with the sealing surface of the seat caused by erosion;

7. It is light in weight, has compact structure and suitable for high-temperature and low-temperature media system (In a range of -204℃-815℃);

8. Ball valve has symmetrical structure so that it can endure the pressure from pipeline perfectly;

9. Overall fully welded ball valve body can also be directly buried in the ground, so that the valve member from erosion, oil and gas pipelines in the most ideal type of valves, maximum useful life of 30 years.

In addition, to ensure the stability of tungsten carbide valve ball, the choice of the material of tungsten carbide ball seat is also can not be ignored. It requires that smaller coefficient of friction, stable physicochemical properties, broader range of temperature, excellent sealing property and so on. Common materials include copolymers of tetrafluoroethylene (PTFE), nylon and some synthetic rubber. However, these materials have also some defects, such as tetrafluoroethylene has a higher coefficient of thermal expansion, poor thermal conductivity, for lack of sensitivity to temperature, when the sealing material hardens, sealing it also decreases, especially when the pressure difference is low. Some synthetic rubber is limited by media types or temperature range, if there is no lubricant, it will be stuck.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Valve Ball Advantages (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 15 February 2016 17:23

Tungsten carbide valve ball uses ball as device for start and stop, which has many functions, such as cutting, distributing and changing the flow direction of the media, specially designed can regulate the flow. From the design of the ball valve, compared with conventional valve, it has many advantages, such as simple structure, excellent sealing property, light in weight, low consumption, small setting size, small volume in a range of certain nominal diameter, small driving moment, easily to start or stop quickly, which becomes the rapidest developing valve in recent years gradually. Tungsten carbide ball combines the advantages of tungsten carbide (high hardness, high strength, high melting point, excellent chemical stability and wear and corrosion resistance) with ball valve can be suitable to the strict conditions of many industries today.

The advantages of tungsten carbide ball valve are given as follow:

1. It has the lowest flow resistance theoretically (Flow resistance refers to the steady state airflow, sound-absorbing material is applied to the sample and the pressure difference across the air flow through the sample line speed ratio.);

2. It has excellent chemical stability and wear or corrosion resistance, which can be contact with most of liquid and some media with corrosive property;

3. It has excellent sealing property at high temperature and high pressure (Nominal pressure from vacuum to 42MPa);

4. Tungsten carbide valve ball using ball as the device for start and stop so that it affected by friction slightly and can be starting or stopping quickly (in a range of 0.05-0.1s), and has small operating impact. In addition, spherical device can endure the higher pressure differential when it close and can achieve automatic position;

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Bismuth Oxide Influencing Tungsten Trioxide Ceramic Property

- Details

- Category: Tungsten Information

- Published on Monday, 15 February 2016 17:16

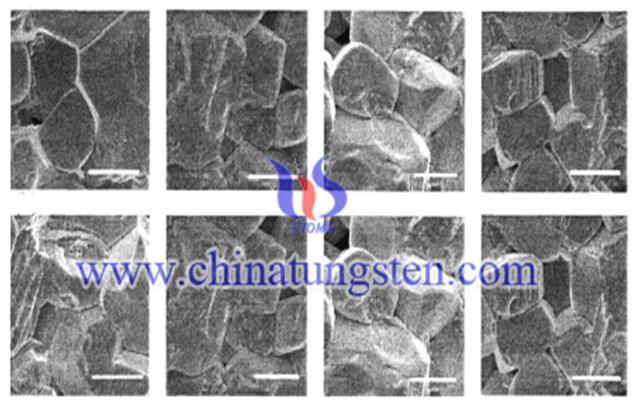

When the doping concentration is 0.2mol% and the sintering temperature is about 1100 ℃, the density of the WO3 ceramics doped Bi2O3 can reach 91%. When the doping concentration is 0.2mol% , WO3 ceramics densification will decline; the sintering temperature is lower than 1100 ℃, the density increases gradually, but when the sintering temperature is 1100 or higher than 1100 ℃, the density of the ceramic will decline ; the best sintering time is 2h, extend the time will make the ceramics sintered density decreases. After analysis, the major causes for this phenomenon are: WO3 melting point is 1273 ℃, Bi2O3 melting point is 860 ℃, the formation of the sublimation are the two substances .

When the doping concentration is 0.2mol% and the sintering temperature is about 1100 ℃, the density of the WO3 ceramics doped Bi2O3 can reach 91%. When the doping concentration is 0.2mol% , WO3 ceramics densification will decline; the sintering temperature is lower than 1100 ℃, the density increases gradually, but when the sintering temperature is 1100 or higher than 1100 ℃, the density of the ceramic will decline ; the best sintering time is 2h, extend the time will make the ceramics sintered density decreases. After analysis, the major causes for this phenomenon are: WO3 melting point is 1273 ℃, Bi2O3 melting point is 860 ℃, the formation of the sublimation are the two substances .

Comparing with non-doped WO3 ceramics, WO3 ceramics doped Bi2O3 varistor voltage declines rapidly, this shows the rapid growth of the ceramic grains causing breakdown voltage drop. When the sintering temperature of WO3 doped Bi2O3 ceramics is 900 ℃, WO3 ceramics do not have pressure-sensitive properties, when the temperature is 900 ℃ ~ 1100 ℃, the pressure-sensitive is maximum coefficient, when the sintering temperature is 1100 ℃, the pressure-sensitive decreases with the temperature rises, it disappears after sintering temperature is higher than 1100 ℃. When Bi2O3 doping concentration is 0.5mol%, the sintering time is 2h.

Doping Bi2O3 having a significant effect on the microstructure of WO3 ceramics; doping can play a role to help promote sintering ceramics; doping can improve the characteristics of the ceramic varistor.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Bismuth Oxide Influencing Tungsten Trioxide Ceramic Grain Growth

- Details

- Category: Tungsten Information

- Published on Monday, 15 February 2016 17:05

Bismuth trioxide (Bi2O3) is known as yellow powder, it dissolves in water, and it does not dissolve in acid generating bismuth (III) salt. Its melting point is 824 ℃, the boiling point is 1890 ℃. Bismuth trioxide may be obtained from natural bismuth Hua (a mineral), its main source is copper, and bismuth powder can be obtained bismuth trioxide in the air combustion. Bismuth oxide is mainly used in the chemical industry (such as chemical reagents, bismuth salt manufacturing, etc.), glass industry (mainly used for coloring), and the electronics industry (electronic ceramics, etc.). Among them, the electronics industry is the most widely used bismuth oxide industry; it is mainly used in varistors, thermistors, and CRT oxide surge arresters and other fields. In addition, Bi2O3 has high refractive index and dielectric constant, significant fluorescence characteristics and inert to water. Therefore, Bi2O3 is potential decomposition and degradation of water pollutants visible catalyst.

Bismuth trioxide (Bi2O3) is known as yellow powder, it dissolves in water, and it does not dissolve in acid generating bismuth (III) salt. Its melting point is 824 ℃, the boiling point is 1890 ℃. Bismuth trioxide may be obtained from natural bismuth Hua (a mineral), its main source is copper, and bismuth powder can be obtained bismuth trioxide in the air combustion. Bismuth oxide is mainly used in the chemical industry (such as chemical reagents, bismuth salt manufacturing, etc.), glass industry (mainly used for coloring), and the electronics industry (electronic ceramics, etc.). Among them, the electronics industry is the most widely used bismuth oxide industry; it is mainly used in varistors, thermistors, and CRT oxide surge arresters and other fields. In addition, Bi2O3 has high refractive index and dielectric constant, significant fluorescence characteristics and inert to water. Therefore, Bi2O3 is potential decomposition and degradation of water pollutants visible catalyst.

Bi2O3 doping WO3ceramics, when the doping has smaller number, the presence of single phase is WO3; when the doping concentration is greater than 0.2mol%, and it will begin to appear as Bi2WO6 phase. Bi2WO6 phase becomes bigger with the sintering temperature increasing. WO3 phase will disappear in the solid phase reaction sintering process. Bi2O3 can promote the rapid growth of WO3 ceramic grain, compact structure, porosity reduction, and a high concentration of Bi2O3 doped in the grain boundary formation of the second phase Bi2WO6 , which increasing the sintering temperature and time, which can promote the growth of WO3 ceramic grains form more Bi2WO6 phase. According to the analysis results, we can get Bi2O3 doping can be formed during the sintering process in the reaction; the transfer material ultimately provides the energy for the growth of the ceramic grains.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com