What Is Tungsten Alloy Rod?

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 July 2025 17:17

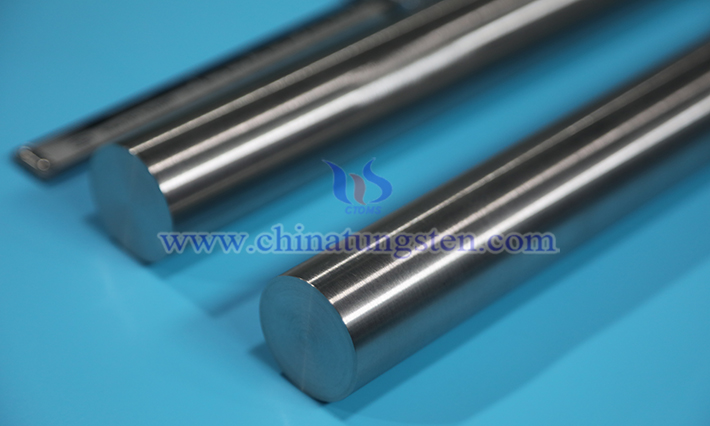

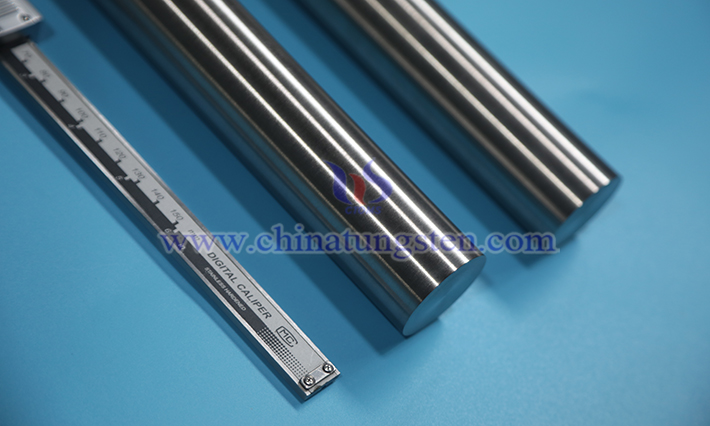

Tungsten-based alloys can be categorized into different types—tungsten alloy rods, tungsten alloy blocks, tungsten alloy plates, and tungsten alloy spheres—based on their external shapes. These alloys share similar physical and chemical properties but differ in their specific applications.

Tungsten alloy rods, also known as tungsten bars, are alloy products made with refractory metal tungsten as the hard phase, supplemented by metal elements such as cobalt, nickel, iron, and copper as binding phases. Leveraging their excellent physicochemical properties, they are widely used across various fields.

In terms of physical and chemical properties, tungsten rods combine the advantages of tungsten and the binding phase, exhibiting a high melting point, high density, high hardness, high strength, low thermal expansion coefficient, high elastic modulus, as well as wear resistance, high-temperature resistance, and good electrical and thermal conductivity. It is worth noting that the actual physicochemical properties of the alloy vary depending on the raw material ratio. For example, when using copper as the binding agent, the alloy’s color shifts toward copper as the copper content increases; meanwhile, its melting point, density, and hardness decrease to some extent, while its electrical and thermal conductivity improve.

In terms of production techniques, the manufacturing methods for tungsten alloy rods differ based on their chemical composition. For instance, tungsten-nickel-iron alloy rods can be produced using powder metallurgy or injection molding techniques. Powder metallurgy involves using metal powders as raw materials, processed through shaping and sintering to create various finished products. Injection molding involves injecting molten colloid into a mold cavity of specific shape under pressure to produce the desired item. Tungsten-copper alloy rods are typically manufactured using the copper infiltration method: tungsten powder is first pressed into a specific shape, sintered into a porous tungsten skeleton, and then subjected to copper infiltration and other processes.

In terms of applications, tungsten rods are widely used across numerous sectors, including military, defense, aerospace, aviation, maritime, lighting, and automotive industries. In terms of processing applications, when tungsten rods are formed into wires, they can be used as filaments, support wires, or lead-in wires; when ground into needles, they meet the needs of specific scenarios; additionally, they can be made into various electrodes and sputtering targets, catering to the functional requirements of different industries.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com