Zumwalt-Class Destroyer Tungsten Alloy Counterweights(1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 18:00

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

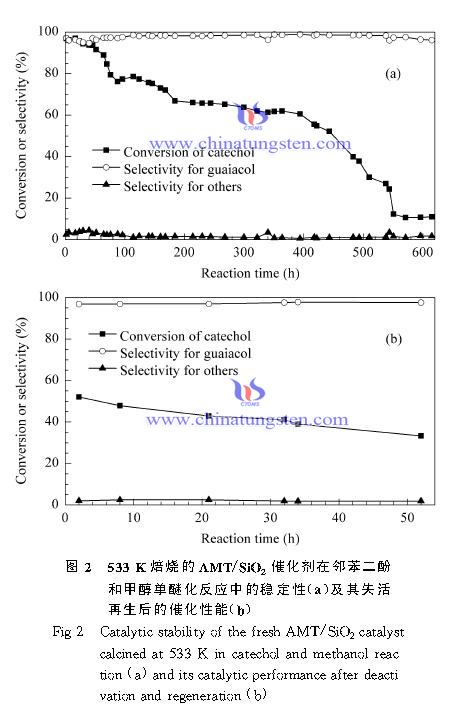

The Lifetime and Recovery Method of Catalyst AMT / SiO2

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 17:38

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coin For Concert

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 17:34

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Catalytic Performance of AMT / SiO2 Calcined at Different Temperature

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 17:34

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coin For Musicale

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 17:32

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Composite Power Warm Compacting Process (2/2)

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 17:18

Continued from the preceding paragraph, Either iron-based materials or tungsten (W), copper (Cu), aluminum (Al) and other metal powder, warm compacting process can be adapted, which also has many advantages, such as:

3. High compacting strength: at the same level of density, temperature and pressure through the green strength of conventional pressing process up compacts 1.25 to 2.0 times, which also facilitates the manufacture of complex mechanical parts powder metallurgy techniques to improve the powder metallurgy technology market competitiveness. Further, since the temperature and pressure after forming green strength is high enough so that it can compact simple machined directly in front of the sintering process, which improves the overall efficiency and the service life of tools;

4. Small release pressure: Compared to the conventional pressing process, stripping process in warm compaction pressure fell by more than 30%. This means that to a certain extent can reduce mold wear to extend its service life and easy-to suppress parts of complex shape. Moreover also by reducing the amount of feed powder lubricant, making the overall density of the compacts have been further improved;

5. Small elastic aftereffect: dimensional change after the sintering temperature and pressure process than conventional tungsten copper parts pressing process is much smaller sintering shrinkage is also smaller and easier to improve the dimensional accuracy of tungsten copper parts;

6. Excellent mechanical properties: in the case of material with the same density, temperature and pressure process using material prepared than the ultimate tensile strength of the multi-pressure sintering improved about 10%, the fatigue strength increased 10-40%;

7. Low relative cost: Although the temperature and pressure of the relative cost compared to the conventional process once the pressing process has increased the cost, but it is still lower than sintering process, copper leaching process, powder forging process.

In addition, in order to make tungsten copper products have excellent comprehensive properties, tungsten copper composite powder warm compacting process should focus on some main parameters, which includes the powder (granularity, content, porosity, apparent density, etc.), the lubricant additives (effect on temperature, friction factors, volatility, oxidizability, etc.), temperature controlling.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Composite Power Warm Compacting Process (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 17:16

Warm compacting process is a kind of new process of high precision powder metallurgy that develops based on conventional molding process. Compared with conventional process, warm compacting process is in the process of pressing the powder in a conventional method and the mold is heated to a certain temperature after pressing to obtain a high-density powder compacts, which flies high density and high performance sintered body. Generally, the pre-heating temperature is between 100-150℃. Due to it is at the range of the room temperature and hot pressing temperature, which is so-called warm compacting. The standard warm compacting process can be density iron-based parts increased from room temperature to suppress (600 ~ 800MPa) of 6.6-6.8g / cm to 7.25-7.45g / cm, and the process cost and lower than the pressure recovery, re-burn, copper infiltration, forging.

In addition, this method can be obtained by pressing a high-performance powder metallurgy products, its high efficiency, high precision characteristics has become one of the faster process of powder metallurgy parts production technology in development. Either iron-based materials or tungsten (W), copper (Cu), aluminum (Al) and other metal powder, warm compacting process can be adapted, which also has many advantages, such as:

1. High density of compacting and sintering: Under the same compacting force, compared to conventional pressing process density can be increased 0.15-0.30g / cm3. Corresponding density required to obtain communication pressing force can be reduced by about 140MPa. This allows suppression of a larger size in the powder press lower tonnage, moderate density of powder metallurgy (PM) parts to create the conditions to increase the tonnage of the press;

2. Uniform compact density distribution: using warm compaction density tungsten copper fittings difference between conventional pressing process is lower than 0.1-0.2g / cm3;

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Exploring Tungsten Trioxide Electrochromic Material

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 16:22

Electrochromic material that is the material occurs by adding material to an electric field. Electrochromic mechanism is more complex, tungsten trioxide (WO3) is an electrochromic material first to be discovered, and it is also the first to be made of electrochromic devices, but its color principle has been a controversial topic. Researchers studied by performing color performance, established a variety of models to explain the mechanism of color, for example, color center model, price between charge transport model, polarization model, free carrier models, but these models can not explain tungsten trioxide electrochromic mechanism.

Electrochromic material that is the material occurs by adding material to an electric field. Electrochromic mechanism is more complex, tungsten trioxide (WO3) is an electrochromic material first to be discovered, and it is also the first to be made of electrochromic devices, but its color principle has been a controversial topic. Researchers studied by performing color performance, established a variety of models to explain the mechanism of color, for example, color center model, price between charge transport model, polarization model, free carrier models, but these models can not explain tungsten trioxide electrochromic mechanism.

Although there are not mechanisms for tungsten trioxide electrochromic, researchers had already learned how to apply tungsten trioxide electrochromic properties and has made tungsten trioxide electrochromic devices come out, and tungsten trioxide electrochromic properties has applied in many areas of life.

There have been a variety of different structures of tungsten trioxide electrochromic devices. As the illustration shows the sandwich-type five-layer structure of the electrochromic device of tungsten trioxide is transparent glass. The upper and lower layers are the cover layer; and the five middle orders from the top are the transparent conductive layer - the electrochromic layer - ionic conductor layer - ion storage layer - transparent conductive layer.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Electric Property

- Details

- Category: Tungsten Information

- Published on Monday, 22 February 2016 16:12

When current flows through a conductor, the conductor may have a fever, this heat generated by the current, called electric, or it can be understood as electric power is generated by the heat, the phenomenon of electrical energy becomes into internal energy. The use of electric principle can be made into various electric heaters, such as electric irons, electric stove, electric irons, electric ovens, water heaters, electric hatch boxes.

When current flows through a conductor, the conductor may have a fever, this heat generated by the current, called electric, or it can be understood as electric power is generated by the heat, the phenomenon of electrical energy becomes into internal energy. The use of electric principle can be made into various electric heaters, such as electric irons, electric stove, electric irons, electric ovens, water heaters, electric hatch boxes.

Electric material is a new energy material which has relatively traditional energy with small size, no noise, no pollution, long life and other characteristics. Thermoelectric materials can be used as electricity and thermal energy conversion intermediary material. The material will appear the temperature difference, and this electric conversion is reversible. Conventional thermoelectric materials have high ZT value (figure of merit, the higher the coefficient, the higher thermoelectric conversion efficiency), and the preparation of a mature technology, it has been widely used in thermoelectric power generation and refrigeration device. Some researchers are finding new thermoelectric materials, although these materials have a higher ZT value, it is the most toxic and precious metal alloys division, the use of these materials will increase in the environment.

Tungsten trioxide (WO3) as important high-tech materials in the electrochromic, the light catalytic degradation, the gas detection and other areas has a wide range of potential applications. WO3 is an n-type thermoelectric material at the same time. Currently, the status quo is thermoelectric materials research with P-type thermoelectric material, but it is necessary for the production of thermoelectric devices p-type matches with n-type. Early, studies have shown that WO3 doped thermoelectric performance, which has been improved. If we find a important dopant and it will be the best process parameters for WO3 thermoelectric properties, it is possible to WO3 used in thermoelectric materials.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sapphire Single Crystal Growing Tungsten Crucible Thermal Stress Analysis

- Details

- Category: Tungsten Information

- Published on Friday, 19 February 2016 17:15

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com