Preparing Tungsten Trioxide Fiber

- Details

- Category: Tungsten Information

- Published on Thursday, 25 February 2016 15:52

Fiber refers to the material from continuous or discontinuous filaments thereof. In plants and animals, fiber plays an important role in maintaining organizations. Fibers can be woven into thin, thread and twine, paper or fabric woven fibrous mat; fibers are also used to manufacture materials, and other materials to form composite material. Natural fibers are naturally occurring, we can get fiber naturally, and fibers are divided into different types according to their origins, animal fibers, plant fibers and mineral fibers. In addition, there are chemical fibers, synthetic fibers, synthetic fibers, inorganic fibers and the like. Filling fibers can effectively improve the strength and rigidity of the plastic, reinforce plastic rigid structure.

Fiber refers to the material from continuous or discontinuous filaments thereof. In plants and animals, fiber plays an important role in maintaining organizations. Fibers can be woven into thin, thread and twine, paper or fabric woven fibrous mat; fibers are also used to manufacture materials, and other materials to form composite material. Natural fibers are naturally occurring, we can get fiber naturally, and fibers are divided into different types according to their origins, animal fibers, plant fibers and mineral fibers. In addition, there are chemical fibers, synthetic fibers, synthetic fibers, inorganic fibers and the like. Filling fibers can effectively improve the strength and rigidity of the plastic, reinforce plastic rigid structure.

Tubular tungsten trioxide nano fibers can be used to make gas sensors with high sensitivity and good stability; it shows a bright prospect in the field of gas sensor. Tubular tungsten trioxide fibers can be prepared by template method that has good controllability. This method can use its space limitations and the role of template debugging effect to control the size, morphology, structure and arrangement of the synthetic material.

Making tungstic acid as source of tungsten, placing tungsten acid in the container, and adding the container to the hydrogen peroxide and ethanol, and stirring constantly; immersing AAO template in tungsten trioxide sol about 30min, then rinsing with demonized water, and placing it about 30min in the air, and heating it at 550 ℃ for 6h in the environment, drying it, finally we can obtain similar tubular fiber tungsten trioxide .

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

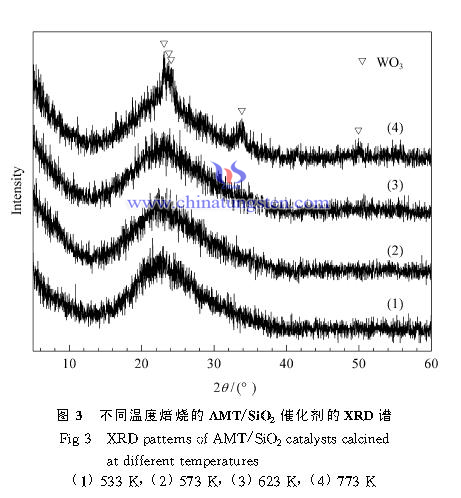

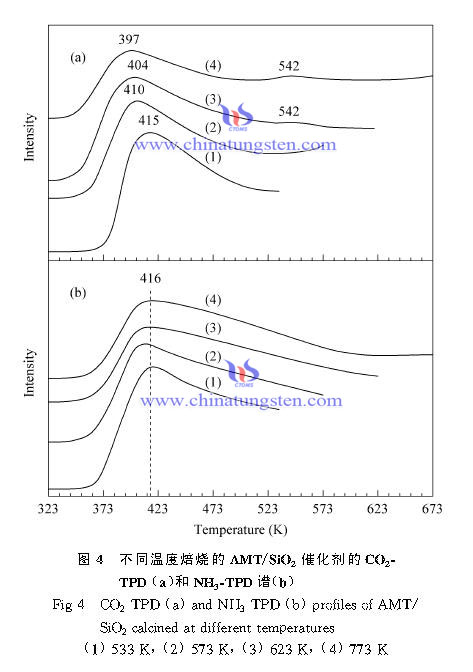

AMT / SiO2 Catalyst Characterization Results

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 18:27

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Producing Crystalline Ammonium Metatungstate Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 18:23

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Waste Denitration Catalyst Recovering Tungsten and Vanadium

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 17:58

Denitration catalyst, being the hard-core of SCR denitrification technology, will lose activity due to wear and clogging, alkali metal poisoning and other reasons in the running process. Besides, it’s hard to separate V2O5 and WO3 out, because the two main components are so similar metal oxides, further more, there are T12 and glass fiber exist in the waste flue gas denitration catalyst. Nowadays, the way to deal with waste catalyst is landfill in universal, the technology about it is still in research stage. A research has introduced a method for recovering W and V from waste denitration catalyst, and the steps are as follows:

1. Grinding the catalyst and adding sulfuric acid to acid splitting, and then add water to obtain titanyl sulfate solution;

2. Filter the solution that obtained in step 1, collecting the residue for further using, and hydrolysis after the filtrate being heated and concentrated to generate product;

3. Filter hydrolysis products, and carry out settlement;

4. Take supernatant after filtering, and adding NH4Cl in the excess amount; filtering again after fully reaction to obtain ammonium metavanadate; then recovering V in the form of pure V2O5 from ammonium metavanadate by calcine;

5. Add excess amount of ammonia with 10%~28% concentration into residue obtained in step 2; and then heated to 80~100℃ to generate APT crystal; then carry out drying and calcinations to recover W in the form of WO3.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Process — Deformation Processing (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 17:09

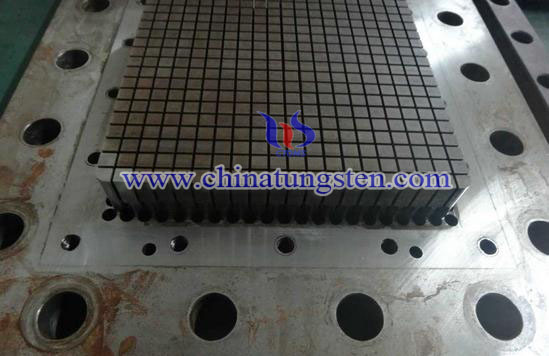

The related researchers adapted different proportions of tungsten-copper alloy (W-20Cu, W-30Cu, W-40Cu) products after infiltrated for cold rolling and intermediate annealing at the deformation process, each pass compression 5% -10%, up to 50% of the total final amount of deformation. Wherein the amount of deformation <25%, the material is only deformed in copper; when the amount of deformation reaches 50%, tungsten materials began to stretch along the rolling direction. Some foreign scholars sintered density of the obtained tungsten copper W-40Cu material extrusion, hot forging and cold forging obtained after tungsten copper rod; a sintered density of only 75% of the tungsten copper plate W-40Cu after cold rolling billet can be made of tungsten copper sheet; and cold rolled billet, and then cold-rolled, cold drawing was also prepared tungsten wire having a diameter of 0.3mm of material.

This deformation after machining tungsten copper alloy has fully dense tissue, mechanical strength and excellent electrical and thermal conductivity, which can be widely used in many areas of application and to meet different needs. Compared with cold deformation processing, hot deformation process refers to the metal under the recrystallization temperature of the plastic deformation, the common processing methods includes bending forging, hot pressing and pulling molding. Different from cold deformation processing (Since the process breaking the original balance of forces inside the metal, resulting in the release of stress, the original force balance is broken and the deformation, which does not reach yield point of the metal material), metal hot deformation processing has plastic deformation and reaches the yield point of the material. However, it is difficult to control the processing temperature, which can not ensure the structure and comprehensive properties of tungsten copper completely.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Process — Deformation Processing (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 17:07

Tungsten copper product is commonly fabricated by powder metallurgy (PM) and infiltration. Due to the large difference of hardness and melting point of tungsten (W) and copper (Cu) and completely immiscible, it is also known as two-phase psudoalloy. Through its incorporation of tungsten powder or after forming part of a mixed copper powder special suppress internal communication pore tungsten skeleton, tungsten copper alloy is further formed by copper infiltration process with relatively high density, the excellent properties. At present, there have been superfine nano-crystalline tungsten-copper alloy, the microscopic structure is more reasonable and stable, relative density and intensity has also increased significantly, but its plasticity and ductility is relatively low, can not meet the particular requirements of some products (such as sheet, for wire, foil, etc.), and therefore the study of the deformation processing of tungsten copper alloy material has also become a hot topic.

For the deformation processing of tungsten copper material, we can specifically divide it into two types, one is cold deformation processing, another is heat deformation processing. From the definition, cold deformation processing is a kind of plastic deformation processing under recrystallization temperature. With the development of the core technology of mechanical processing industry, the production of more and more molded parts are manufactured by cold mold, types of cold deformation of the mold used more. Volume cold forging (cold heading, cold extrusion, stamping, etc.); sheet metal stamping (such as drawing, blanking, cutting, punching, etc.); material rolling (cold rolling wheel molding, etc.). Although many types of cold deformation of the mold, different working conditions, performance requirements are different, but the basic work in close: that was so in the cold state of the metal deformation, withstand greater shear force at work, pressure, bending force, impact and friction.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding Container for Nuclear Mine

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 16:50

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Nanorods Characterization

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 16:18

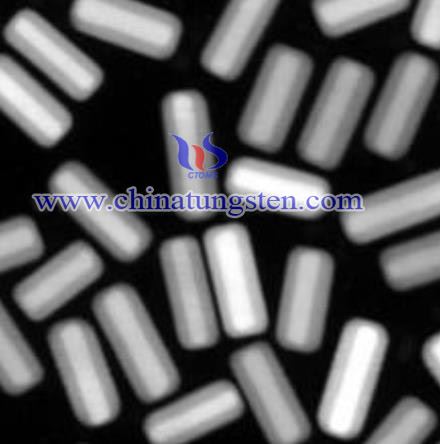

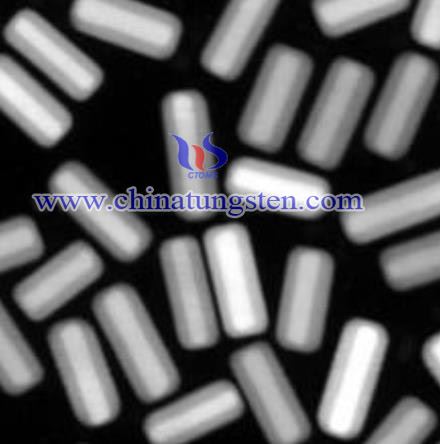

Nanorod is rod-shaped nanoparticles scale from a few nanometers to hundreds of nanometers; it is relatively stable and abundant physical and chemical properties. Surface plasmon resonance wavelength nanorods with aspect ratio can be changed. Because of its unique optical, photovoltaic, solar thermal, photochemical, and molecular biological properties, nanorod caused many concerns by materials scientists, biochemists, physicians, physicists, micro- Electronics engineers and other scientists on the extensive and intensive studies.

Nanorod is rod-shaped nanoparticles scale from a few nanometers to hundreds of nanometers; it is relatively stable and abundant physical and chemical properties. Surface plasmon resonance wavelength nanorods with aspect ratio can be changed. Because of its unique optical, photovoltaic, solar thermal, photochemical, and molecular biological properties, nanorod caused many concerns by materials scientists, biochemists, physicians, physicists, micro- Electronics engineers and other scientists on the extensive and intensive studies.

In the growth process of tungsten trioxide nanorods, sodium ions preferentially adsorbed in the surface of the tungsten trioxide crystal, the crystal surface inhibits the growth of tungsten trioxide nanorods under visible light, which shows better catalytic performance, and gas sensing performance, the test results show that tungsten trioxide nanorods operating temperature is low, and trimethylamine trioxide has a high sensitivity and good response and recovery time, the material shows a good prospect.

When the molar ratio of sodium sulfate and sodium tungstate is 4: 1, XRD diagrams of the various hydrothermal can be seen when the water heated for longer than 24h, the product is pure hexagonal tungsten trioxide in the hydrothermal time 6h , the hexagonal tungsten trioxide (200 planes) has emerged, and (001) planes appeared until 12h, which suggests that the early stages of tungsten trioxide hexagonal crystal growth (200) crystal surface is an advantage, it has adsorbed in solution; reducing the chance of tungsten trioxide crystals to the (200) plane growth of tungsten trioxide to make it another advantage crystal face (001) growth, the (001) crystal face has a significant growth after 48h, tungsten trioxide nanorods becomes in the hydrothermal.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Nanorods Synthesis

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 16:06

Tungsten trioxide nanorods are synthesized by 2.77g of sodium tungstate and 4.77g of sodium dissolved in 67.5ml of water , stirring, adjusting 3mol / L hydrochloric acid to pH 1.5, stirring it 30min, heating it at 180 ℃ in above solution 48h, washing three times with ethanol, drying at 65 ℃ in the environment, it can be prepared nanorods of tungsten trioxide, which is a single crystal nanorods.

Tungsten trioxide nanorods are synthesized by 2.77g of sodium tungstate and 4.77g of sodium dissolved in 67.5ml of water , stirring, adjusting 3mol / L hydrochloric acid to pH 1.5, stirring it 30min, heating it at 180 ℃ in above solution 48h, washing three times with ethanol, drying at 65 ℃ in the environment, it can be prepared nanorods of tungsten trioxide, which is a single crystal nanorods.

Tungsten trioxide nanorods are dissolved by sodium tungstate and sodium sulfate water, after stirring, adjusting the pH value, washing and drying to obtain tungsten trioxide nanorods. In the synthesis process, the selection of the sodium salt can be as director of synthesizing tungsten trioxide nanorods, and director is not the product of rod-shaped morphology.

Preparation of tungsten trioxide obtained nanorods can be observed by electron microscopy. Nanorods is 1-5μm in length, between 25-40nm in diameter, the tungsten trioxide has a high aspect ratio nanorods; the diameter of single trioxide nanorod is 30nm, the lattice fringes are clearly visible, this indicating is higher degree of crystallinity nanorods; this also shows the two intertwined lattice fringes, and hexagonal tungsten trioxide contrast can be found in the two planes are (001) and (200) planes, wherein the (001) planes are grown.

Although the tungsten trioxide nanorods preparation process shows a good prospect, it is still in the laboratory research stage. We should increase research and development, strengthen exchanges and cooperation in various fields between basic researches and make its research and application level to be improved, make it as soon as possible apply to industrial production.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coin For Graduation Ceremony

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 13:44

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com