Waste Denitration Catalyst Recovering Tungsten and Vanadium

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 17:58

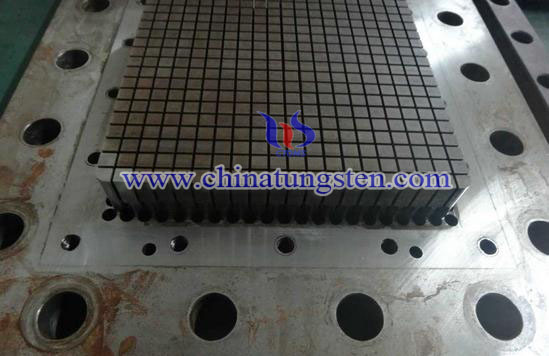

Denitration catalyst, being the hard-core of SCR denitrification technology, will lose activity due to wear and clogging, alkali metal poisoning and other reasons in the running process. Besides, it’s hard to separate V2O5 and WO3 out, because the two main components are so similar metal oxides, further more, there are T12 and glass fiber exist in the waste flue gas denitration catalyst. Nowadays, the way to deal with waste catalyst is landfill in universal, the technology about it is still in research stage. A research has introduced a method for recovering W and V from waste denitration catalyst, and the steps are as follows:

1. Grinding the catalyst and adding sulfuric acid to acid splitting, and then add water to obtain titanyl sulfate solution;

2. Filter the solution that obtained in step 1, collecting the residue for further using, and hydrolysis after the filtrate being heated and concentrated to generate product;

3. Filter hydrolysis products, and carry out settlement;

4. Take supernatant after filtering, and adding NH4Cl in the excess amount; filtering again after fully reaction to obtain ammonium metavanadate; then recovering V in the form of pure V2O5 from ammonium metavanadate by calcine;

5. Add excess amount of ammonia with 10%~28% concentration into residue obtained in step 2; and then heated to 80~100℃ to generate APT crystal; then carry out drying and calcinations to recover W in the form of WO3.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com