Difference Between Tungsten Disulfide and Molybdenum Disulfide

- Details

- Category: Tungsten Information

- Published on Monday, 15 February 2016 16:46

Tungsten disulfide can take place of molybdenum disulfide in almost every field with even more wider application. Molybdenum and tungsten is in the same phrator of chemical element, chemical property of tungsten is more stable and higher molecular weight. Molybdenum is widely used due to its low price and high efficiency of marketing supplement. In fact, tungsten disulfide is not newly developed product, its application history is all the way with molybdenum disulfide. Due to its high price, it is firstly used in NASA aerospace, military, automobile industry and so on. A few years ago, price of tungsten disulfide is ten times higher than molybdenum disulfide. Nowadays price of molybdenum disulfide is increasing rapidly. And the price of these two materials is the same. So it would be more valuable if tungsten disulfide is used.

Differences between tungsten disulfide and molybdenum disulfide:

Note:PSI=6.89×103Pa

|

Property |

Tungsten Disulfide(WS2) CAS No 12138-09-9 |

Molybdenum Disulfide(MoS2) CAS No 1317-33-5 |

|

Color |

Silver grey |

Blue silver grey |

|

Appearance |

Crystalline |

Crystalline |

|

Melting Point(℃) |

1250~1260 (Decompose) |

1185 (Decompose) |

|

Boiling Point(℃) |

/ |

450 |

|

Density(Kg.m-3) |

7500 |

5060 |

|

Molecular Weight |

248 |

160.08 |

|

Friction Coefficient |

Static state0.07; Dynamic state0.03 |

/ |

|

Thermostability |

594oC(1100oF),COF <0.1 |

316oC(600oF),COF <0.1 594oC(1100oF),= 0.5 |

|

Carrying Capacity |

Coating 2000Mpa (300,000 psi);Under138Mpa(20,000 PSI),COF=0.044; Under138Mpa 2756Mpa (200,000~400,000 PSI ),COF reduce to 0.024 |

Coating 250,000 PSI |

|

Lubricant Temperature Range(℃) |

Environmental temperature: -273~650;Vacuum(10-14Torr): -188~1316 |

Environmental temperature : -185~350;Vacuum (10-14Torr): -185~1100 |

|

Chemical Stability |

Inert matters, odorless |

Inert matters,odorless |

|

Magnetism |

Non-magnetism |

Non-magnetism |

|

Electrical Characteristics |

Semi-conductor property |

/ |

|

Rockwell Hardness(HRC) |

30 |

/ |

|

Coating Thickness(Microns) |

0.5 |

/ |

|

Corrosion Resistance |

Slow down the corrosion process but not completely resist |

/ |

|

Coating Material |

Iron, steel, aluminum, copper, plastic and other artificial solid material |

Iron, steel, aluminum, copper, plastic and other artificial solid material |

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Electrode Liquid-phase Sintering Theory (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 17:08

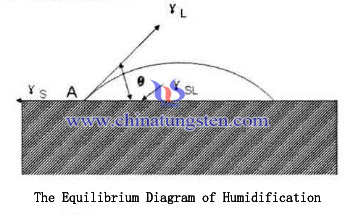

From the thermo dynamics of view, Equilibrated at the point of contact of the solid and liquid phases must meet γS = γSL + γLcosθ. θ is the wetting angle or contact angle, when completely wet, θ = 0 °, then γS = γSL + γL; partial wetting, 0 °< θ < 90 °; completely non-wetting, θ> 90 °, this time γS ≥ γSL + γL. Liquid phase sintering occurs must satisfy θ < 90 °, only with complete wetting liquid or partially wet to penetrate the pores and grain gap, forming a network-like structure of the coating. If θ > 90 °, the liquid produced during sintering will quickly bleed sintered body, densification can not be successfully completed, so that the group of tungsten copper alloy phase changes occurs.

View from the classical liquid-phase humidification theory, Only when we can see the surface energy of the solid and liquid phases is greater than the sum of the solid - liquid interfacial energy, that WSL = γS + γL - γSL in WSL> 0, when the liquid in order to effectively wet the solid surface. Solid phase has certain solubility in the liquid phase will help to improve wettability, promoting an increase in the number of liquid can be carried out by means of liquid mass transfer, and dissolved in a liquid phase in the process of dissolving precipitated solute portion may be carried out to fill the solid phase defects and particle clearance particle surface, thereby further improving the solid phase particle distribution uniformity. The quantity of liquid phase required to meet the solid particles fill the gaps, reduce the porosity of the material, increasing the density of the material, generally 20% -50% of the volume of liquid phase sintering of the best accounts, exceed prone to sintering deformation is insufficient so that the liquid can not be filled solid tungsten skeleton pore and solid particles come into contact with each other and the grains will grow up.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Electrode Liquid-phase Sintering Theory (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 17:07

Tungsten copper electrode has both advantages of tungsten (W) and copper (Cu), such as high melting point, high density and high hardness of tungsten, excellent thermal and electrical conductivity of copper. Due to the big difference between tungsten and copper (the melting point of tungsten is 3387℃, the melting point of copper only 1083℃), it makes tungsten copper sintering become a typical liquid-phase sintering.

During the liquid-phase sintering process, Solid solubility in the liquid phase, the solid and liquid phases of liquid interfacial energy and the ability to penetrate the solid phase along the grain boundaries greatly affected the speed of change in the sintering and microstructure. In addition, the parameters, such as the granularity of particle distribution, powder purity, sintering temperature, sintering time, sintering atmosphere and the compact density are all the significant influencing factors of tungsten copper electrode. Liquid-phase sintering must meet wettability, solubility, phase number three conditions, the wettability of the solid, liquid surface tension (specific surface energy) interfacial tension γS, γL and two-phase (interfacial energy) γ are decided.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Recovery of Mother Liquor for Preparing Ammonium Paratungstate by Ion Exchange Method

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 16:34

Most of ammonium paratungstate (APT), about 80% is produced by ion exchange from the raw material of tungsten ore in tungsten metallurgy in China. There are three main steps in ion exchange: decompose tungsten ore, ion exchange, evaporate and crystallize. Today we provide a method that not only can remove Mo, Sb, As, Sn at one-time, but also recycle NH4Cl, improve the recovery rate of WO3, and eliminate waste water.

0-95% of the mother liquor is returned for preparing desorption agent, the remaining returned to prepare pre-ion-exchange solution, and take the following two ways according to the contents of impurities in the crystallization mother liquor:

1. If the mass ratio of WO3/Mo in ammonium tungstate produced by ion exchange is below 5000, adding (NH4)2S for vulcanization. Conditions for the vulcanization are: vulcanize at 10-75℃, use amount of 0.5-3g/l more than theoretical, then add copper sulfate or chloride or Cu(Ac)2 at temperature of 10-80℃, the amount of Cu2+ is 3-6 times of the theoretical. Filter after kept 1-3 hours, and the filtrate is evaporated and crystallized to prepare APT, crystallization mother liquor returned back directly.

2. if the mass ratio of WO3/Mo is upper than 5000, evaporate and crystallize to generate APT directly. Add (NH4)2S into the crystallization mother liquor in advance for vulcanization. Conditions for the vulcanization are: vulcanize at 10-75℃, use amount of 1-3g/l more than the theoretical, then add copper sulfate or chloride or Cu(Ac)2 at temperature of 10-80℃, the amount ofCu2+ is 3-6 times of the theoretical and filter after heat preservation for 1-3 hours, filtrate return to reuse.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparation Method for Uniform Mixing Sodium in Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 16:30

The main process for preparing coarse grain carbide crystal in China is adding alkali metals such as sodium in tungsten trioxide to generate coarse grain tungsten powder after hydrogen reduction, and carbonization at high temperature to get coarse tungsten carbide powder, and then grinding, forming, sintering process to prepare coarse grain carbide. Conventional methods of preparation sodium doped WO3 are spray, artificial doping method, the defects of the two methods is sodium distributing not uniform in WO3 thus affects the subsequent production, and leading particle growing not uniform, products of great difference in properties. Besides, the manufactures may have to buy equipments by using the spray method, thus resulting cost increased. So, is there any way to make the sodium mixed uniform, and do no need to purchase any other equipment? This paper we will provide a method for preparation of WO3 uniform doped sodium.

The main process for preparing coarse grain carbide crystal in China is adding alkali metals such as sodium in tungsten trioxide to generate coarse grain tungsten powder after hydrogen reduction, and carbonization at high temperature to get coarse tungsten carbide powder, and then grinding, forming, sintering process to prepare coarse grain carbide. Conventional methods of preparation sodium doped WO3 are spray, artificial doping method, the defects of the two methods is sodium distributing not uniform in WO3 thus affects the subsequent production, and leading particle growing not uniform, products of great difference in properties. Besides, the manufactures may have to buy equipments by using the spray method, thus resulting cost increased. So, is there any way to make the sodium mixed uniform, and do no need to purchase any other equipment? This paper we will provide a method for preparation of WO3 uniform doped sodium.

Steps are as bellows:

1. Take the ammonium tungstate of WO3 concentrate 200~300 g/L as raw material, and Na+ mass concentration of PPM 10~40;

2. Add solid sodium salt according to the requirements of subsequent products, Na/WO3 about 0.05%~0.25%, mix the solution;

3. Evaporate and crystallize, temperature controlled in 80~100℃ with the stirring speed of 50~200 r/min;

4. The end of crystallization when pH reaches 6.4~7.0, then stop heating and cooling down to 20~50℃;

5. Filter the liquid by vacuum filtration, dry to generate APT powder with uniform sodium;

6. Calcine APT in the claining furnace at 680~740℃to obtain tungsten trioxide powder with uniform sodium.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 16:29

Ammonium metatungstate (AMT) is an appearance of white or slightly yellow crystalline powder, its water-soluble is 300g / 100ml, it slightly soluble in water; when the temperature reaches at 20 ℃, its solubility is less than 2%. Ammonium metatungstate is used in making metal tungsten, steel, fireproof fabric and for the ceramic industry. Usually, we take ammonium tungstate solution as raw material to obtain ammonium metatungstate solution by solvent extraction or ion exchange method, and then evaporate it to prepare crystals of ammonium metatungstate. Ammonium metatungstate is also used in the manufacture of various petrochemical catalysts and other tungsten compounds, and it is the main raw material refinery tungsten-based catalyst. According to the features of ammonium metatungstate slightly soluble in water, we prepare tungsten trioxide in this case.

Ammonium metatungstate (AMT) is an appearance of white or slightly yellow crystalline powder, its water-soluble is 300g / 100ml, it slightly soluble in water; when the temperature reaches at 20 ℃, its solubility is less than 2%. Ammonium metatungstate is used in making metal tungsten, steel, fireproof fabric and for the ceramic industry. Usually, we take ammonium tungstate solution as raw material to obtain ammonium metatungstate solution by solvent extraction or ion exchange method, and then evaporate it to prepare crystals of ammonium metatungstate. Ammonium metatungstate is also used in the manufacture of various petrochemical catalysts and other tungsten compounds, and it is the main raw material refinery tungsten-based catalyst. According to the features of ammonium metatungstate slightly soluble in water, we prepare tungsten trioxide in this case.

Ammonium metatungstate preparing tungsten trioxide is based on taking ammonium metatungstate as raw materials, heating ammonium metatungstate to 220-280 ℃; it can be converted to ammonium metatungstate when it loses some ammonia and crystal water, and then continue to heat ammonium metatungstate to more than 600 ℃, when ammonium metatungstate loses all crystal water and ammonia, cooling and crystallization, the finished product is dried thoroughly into yellow tungsten trioxide.

There many methods of preparation of ammonium metatungstate, such as acid method, thermal decomposition method, ion exchange, solvent extraction method. The method of ammonium metatungstate preparing tungsten trioxide is simple and easy, and it meets the needs of industrial production.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Exploring Tungsten Trioxide Thin film Transmittance

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 16:10

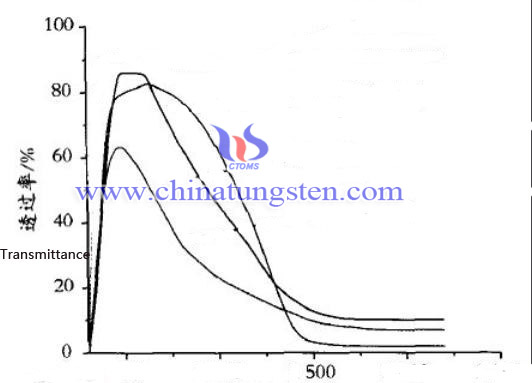

Transmittance is physical vocabulary; it is the efficiency of light showing, the percentage of flux through its incident light flux transparent or translucent display devices. It denotes display device or through the efficiency of light; it directly affects the visual effect of the touch screen. Many touch screens are multilayer composite thin film, touch screen should include at least four characteristics: transparency, color distortion, sharpness and reflective.

Transmittance is physical vocabulary; it is the efficiency of light showing, the percentage of flux through its incident light flux transparent or translucent display devices. It denotes display device or through the efficiency of light; it directly affects the visual effect of the touch screen. Many touch screens are multilayer composite thin film, touch screen should include at least four characteristics: transparency, color distortion, sharpness and reflective.

Analyzing tungsten trioxide thin film by using XRD-600 diffractometer structure and morphology, which shows the transmittance of tungsten trioxide thin films are not different by comparing the sol - gel method and obtained by magnetron sputtering before annealing, and the transmittance of thin film decreases after annealing above 300 ℃, and the higher the annealing temperature, the transmittance is lower. Tungsten trioxide thin film samples are annealed below 350 ℃, the annealed thin film sample is gradually completed amorphous to crystalline transition state within the range of 350 ~ 400 ℃, after annealing at 400 ℃, the substrate also has a diffraction peak.

Different forms of tungsten trioxide thin film samples obtained at different annealing temperatures. In addition, the morphology and optical properties of tungsten trioxide thin films have a great impact on its gas-sensitive properties, such as relatively porous amorphous, which will help the adsorbed gas.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rabbit Tungsten Gold-plated Bar

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 15:45

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-plated Coins For Sports Meeting

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 15:43

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ox Tungsten Gold-plated Bar

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 15:39

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com