Doped Tungsten Wire Low Temperature Ductility Influence Factors

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 11:28

Doped tungsten low temperature ductility is the main influence factor of tungsten wire spooling property, and spooling property will largely affect use efficiency of the bulbs, so understanding the influence factors of low temperature ductility of doped tungsten wire, thereby to expand the applications of tungsten wire.

Theoretically, since the doped tungsten wire grains are longitudinally fibrous structure, and the fracture behavior is intragranular fracture, so it has good ductility. Beside, its plastic-brittle transition temperatures well below than room temperature can well meet the filament winding shaping requirement. However, due to the doped tungsten wire has complex production technology, and in the production process is prone to error, resulting in deterioration of low temperature ductility, affecting spooling property of tungsten wire. Here's a brief analysis of influence factors of the low temperature ductility of doped tungsten wire:

1. The purity of the raw materials

Experimental results show that high-purity tungsten powder having excellent ductility at room temperature, namely, tungsten itself is not brittle. Therefore, low temperature ductility of tungsten will mainly influenced by impurities. Nickel and iron impurity elemental content is too high will increase tungsten wire’s low temperature ductility, resulting in a certain degree difficulty of post-processing.

2. Additives

In order to make tungsten wire has good high temperature sag resistance, tungsten wire will dop some additional agents including Al, Si, and K and so on. But these elements will have no beneficial impact on low temperature ductility performance of the tungsten wire, so during the doping process should better control the amount of additional agents.

3. The surface condition of doped tungsten wire

During the processes, tungsten wire may appear more surface defects, which can mainly be attributed to surface mechanical damage and surface contamination. These defects will increase tungsten wire’s low temperature ductility. In order to eliminate surface defects caused by the machining usually uses electrolytic cleaning method to clean tungsten wire, so that it can improve the surface condition of tungsten wire, increase smoothness. Thereby reducing the tungsten wire’s stress concentration in the process of winding reduces low temperature ductility of tungsten wire.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Seismic Tungsten-rhenium Wire Production

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2016 11:23

Tungsten wire in the field of lighting systems are the most widely used, but to be applied to aircraft, ships and cars lights and other special lighting systems and as high precision gas chromatograph thermal conductivity wire, kinescope wire, UHF tube filament and thermocouple wire need to produce tungsten wire with more favorable properties. The experiment found that tungsten powder further doping rhenium on the basis of doped K, Si, and Al to produce tungsten-rhenium wire has good performance. Tungsten-rhenium wire not only maintain a high temperature sag resistance and improved tungsten room temperature shaping process, thereby improving the seismic performance of the tungsten wire.

Rhenium is a rare metal. At room temperature, it is grayed and crystal structure is sixty thousand close-packed. Its physical properties are as follows: Density: 21.04g / cm3; Melting point: 3180 ℃, the melting point of rhenium only lower than tungsten; boiling point: 5627 ℃; insoluble in hydrochloric acid and hydrofluoric acid. Rhenium is kind of ductility metal at room temperature which is easily formed into a sheet or wire, and the more purity of rhenium the easier molding process. But as the temperature rises rhenium will occurs work hardening in varying degrees, making it difficult to process deformation at high temperature. Therefore, as the additive element adding in tungsten wire can improve the high temperature sag resistance and shaping process at room temperature.

Tungsten-rhenium wire production processes:

1. Adding Si, Al, K and ammonium perrhenate (NH4Re4O) solution into tungsten trioxide (WO3), then after evaporation, drying, sieving, hydrogen reduction and other processes produce rhenium tungsten mixed powder. The doping mode will chose wet doping, because the wet doping can make more uniform distribution of rhenium in the tungsten-based. At the same time compared the effects of different content of rhenium doped on tungsten found rhenium added in an amount of 3% can produce more favorable performance tungsten-rhenium wire.

2. The mixed powder is pressed into a tungsten-rhenium strip, obtained billet after through sintered.

3. Finally, after swaging, drawing and other processes produce tungsten-rhenium wire.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Valve Ball Description (2/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 17:16

In some deep oil well with high content of water and sand, high abrasion, the advantages of high density, excellent wear resistance and corrosion resistance of tungsten carbide valve ball becomes more obvious. Theoretically, the main failure modes include wearing, abrasion, fatigue cracks, collapse and so on, which makes the ball valve material fail earlier in oil drilling (such as bearing steel, ceramics) and shorten the service life (bearing steel is easily corroded by the liquid and has lower wear resistance; ceramics belongs to brittle materials and has lower impact ductility, which is easily to break).

Therefore, tungsten carbide valve ball makes up for the deficiency perfectly, which not only has high hardness, high density, high strength, excellent chemical stability of tungsten (W), but also remarkably improves the bending strength and impact ductility of oil drilling pump valve ball by adding cobalt (Co). Excellent resistance to wear and corrosion resistance greatly improved drilling efficiency, extend tool life, but also reduces operating costs. Recent years, the related researchers and scholars will further shift the focus to the cemented carbide valve ball, especially in the United States and some European industrial countries, tungsten carbide valve ball has been increasingly widely used, the type and quantity are continuing to increase, and toward the high temperature and pressure, high tightness, large-caliber, long service life and multifunction developing. The reliability and overall performance have reached a higher level, has been replaced with a valve part, control valve and end valve. In addition, with the innovation of tungsten carbide valve ball technology, it has a broader applying prospect in oil and gas pipelines, refinery cracker and nuclear industry, especially in medium and large caliber, medium and high pressure fields.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Valve Ball Description (1/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 17:14

Tungsten carbide valve ball or called tungsten carbide ball valve is converted from conventional stopcock. It uses a ball to start and stop by sphere running around the stem axis. Compared with conventional valve, valve ball has many advantages, such as simple structure, excellent tightness, light in weight, lower material consumption, smaller installation size, smaller volume within a certain nominal diameter, smaller driving moment and easy operation for controlling, which becomes one of the most rapid developing of valve gradually in recent years. Tungsten carbide ball valve in the pipe main role is cut off, distribution and change the direction of media flow, other special designed ball valve structure can achieve flow adjustment function.

Tungsten carbide ball (WC-Co) with high precision we discuss here has been widely used in valve ball and ball seat for oil drilling, deep-sea drilling, which is also the most critical component of oil pump. Due to the harsh conditions in oil drilling industry, especially in some sand drain, heavy oil well, high pressure oil well, which contains water, diverse gas, wax, sand and some materials with high corrosivity, the pump need to pump oil from hundreds or even thousands of meters of strata extracted. It requires that the ball valve and ball seat has excellent tightness, wear resistance and corrosion resistance (pumping the ball, with rear seat evacuated to an absolute pressure 0.36kgN / cm2 or less, in the 10s the absolute pressure values do not change).

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate as Raw Material for Preparing Ammonium Metatungstate 2/2

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 16:39

Ion exchange method, specific steps are carried out as follows:

1. Heating ammonium paratungstate(APT) to 130~140℃, and keep the temperature for 1~8 hours;

2. Transfer the formation of step 1 into slurry, and boiled to 80~100℃ for 2~6 hours to form ammonium metatungstate (AMT) solution;

3. Concentrate and crystallization, filtrate to separation, and then dry to get AMT crystal.

Electrodialysis method, the implementation steps are as follows:

1. Add APT into the anode chamber, and electrify;

2. When the electricity passes by, the ammonium ions go into the cathode chamber through the anion exchange membrane, and the concentration of AMT ion in the anode chamber increases;

3. Release the AMT solution from the cathode chamber;

4. Concentrate and crystallization, filtrate to separation, and then dry to get AMT crystal.

Shallow thermal decomposition - resin exchange method, the steps are as follows:

1. Place the APT in the enamel plate, and put them in a constant temperature oven at 240℃ heated for 25~30 minutes;

2. Remove the reactants, slowly pour into pure water of 95℃ with stirring;

3. Add L type resin when the majority of solid is dissolved, control pH value between 3~4, and stir for 30min in an environment of constant temperature;

4. Filter he mixture through a stainless steel screen to remove resin and debris;

5. Lay aside the filtrate for 12 hours, then vacuum filtration to remove insoluble impurities and tungsten compounds;

6. Heat and condense to crystallization, and drying by 50-60℃ air for 2 hours to obtain AMT crystal.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate as Raw Material for Preparing Ammonium Metatungstate 1/2

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 16:32

Ammonium metatungstate (AMT) is an important intermediate product of tungsten metallurgy, a white crystal or yellow powder which is easy to dissolve in water, but insoluble in alcohol. AMT can be used in preparing tungsten, alloy steel, fire proof fabric, etc. and also be used for ceramic industry. It’s also used in the manufacture of various petrochemical catalysts and other tungsten compounds which is the raw material of catalysts based on tungsten. There are many ways to generate AMT, such as tungstate, ion exchange, thermal decomposition method and so on. This paper, we would like to introduce some methods that preparing AMT base on material of ammonium metatungstate (APT).

Neutralization method – take APT and nitric acid as raw materials to generate AMT, the specific steps are as follows:

1. Add ionized water n and citric acid into APT to form a mixture that concentration of WO3 12% ~ 30%;

2. According to the ratio of APT: nitric acid equals to 1:20, adding nitric acid which the concentration is 3% to 5% into APT slurry;

3. Control solid-liquid ratio at 1: (3~4), and pH controlled in 2~4, heating and dissolve to make the relative density of the solution about 1.18~1.20. Then heated to 80~90℃, keep the temperature and pH value constantly, stir for 4h, aging for several hours;

4. Concentrate the solution until the WO3 content is about 50%, filtering to remove the insoluble substance, and keep concentrating, then cooling down to 80℃ and drying get AMT.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

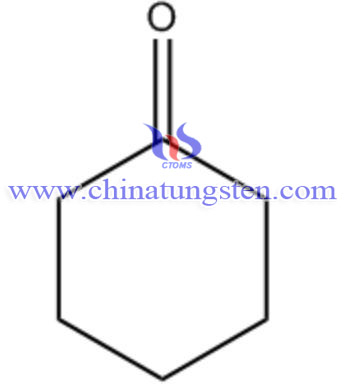

Temperature Influencing Tungsten Trioxide Preparing Cyclohexanone

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 16:19

Cyclohexanone is organic compound, it is carbonyl carbon atom including the six-membered ring saturated cyclic ketone; it is colorless and transparent liquid, it containing traces of phenol. Cyclohexanone impurities are yellow. Cyclohexanone has a carcinogenic effect; it is mainly used in industrial organic synthesis of raw materials and solvents. Cyclohexanone is an important chemical raw materials, it is widely used in nylon, caprolactam and adipic acid intermediate principal. It is also an important industrial solvent, such as for paints, in particular for nitrocellulose, vinyl chloride polymers and copolymers or methacrylic acid ester polymer paint.

Tungsten trioxide catalytic preparing cyclohexanone are affected by many factors. We analyze them by the table in order to have further investigations on the effects for different polymorphs WO3 catalyst preparing cyclohexanone yield:

|

catalyst |

Calcination temperature / ℃ |

polymorph |

cyclohexanone yield /% |

|

|

Without methanol |

Adding 5mL methanol |

|||

|

WO3-200 |

200 |

Rhomboidal |

69.6 |

84.2 |

|

WO3-300 |

300 |

hexagonal |

72.3 |

83.8 |

|

WO3-400 |

400 |

hexagonal |

78.7 |

84.9 |

|

WO3-500 |

500 |

triclinic |

78.0 |

85.4 |

|

WO3-600 |

600 |

monoclinic |

73.5 |

88.0 |

As we can see from the table above, catalyst WO3 form is changing with calcination temperature,, but the change of the cyclohexanone yield is not obvious, which can describe the reaction of crystalline WO3 has little effect.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Alkoxide Method Preparing Tungsten Trioxide Thin Film

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 16:09

Tungsten trioxide thin films has optical properties, electrical properties, magnetic properties, chemical properties, mechanical properties, thermal properties, etc., it has a variety of properties and thus be applied in many fields, for example, it is used as electrical film, optical film, hard film corrosion film, lubricating film, decorative film, packaging film. Among the many film material, tungsten trioxide thin films have good electrochemical performance, so it has been widely used, such as discoloration smart windows, gas sensors, pH meter and so on. At the present, many researchers have studied tungsten trioxide thin film material, especially the photochromic electricity and electrochemical properties.

Tungsten trioxide thin films has optical properties, electrical properties, magnetic properties, chemical properties, mechanical properties, thermal properties, etc., it has a variety of properties and thus be applied in many fields, for example, it is used as electrical film, optical film, hard film corrosion film, lubricating film, decorative film, packaging film. Among the many film material, tungsten trioxide thin films have good electrochemical performance, so it has been widely used, such as discoloration smart windows, gas sensors, pH meter and so on. At the present, many researchers have studied tungsten trioxide thin film material, especially the photochromic electricity and electrochemical properties.

Preparation steps:

1. Putting the base W into the alkoxide solution in dry N2 atmosphere, pulling out of the base by the electric;

2. Drying and removing excess organic solvent in an atmosphere of dry nitrogen coating, the process should be about 30min;

3. Ensuring sufficient hydrolysis to form gel films in humidity atmosphere of 30%, so that W-OR (organic material) can become into W-OH and R-OH (finally evaporated), this process can keep1h;

4. Heating the thin film, the treatment consists of two processes: the first step is heating it at 200 ℃, keeping it 30min; the second step is heating it at 430 ℃ , and removing the residual organic solvent, so as to form thin film of tungsten trioxide.

The study shows that tungsten trioxide thin film density is lower than the material density (7.16g / cm³), it is 0.57 before the heat treatment, and it becomes 0.64 after annealing at 180 ℃, which leads tungsten trioxide thin film to form microcrystalline structure.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gemini Tungsten Gold-plated Coins

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 10:21

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Arise Tungsten Gold-plated Coins

- Details

- Category: Tungsten Information

- Published on Thursday, 04 February 2016 10:19

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com