Using Microwave Method Producing Tungsten Vanadium Dioxide (2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 16:33

Vanadium dioxide (VO2) in the temperature range of 68 ℃ is easy cause phase change, which can limit VO2 application scope. Doping can effectively change the VO2 phase transition temperature, making it can widely use in other fields, so now there are many methods for doped VO2. And experiment found VO2 film can be further reduced VO2 powder’s phase transition temperature. Therefore, using microwave plasma method to produce tungsten vanadium dioxide thin films with doping nitrogen has low transition temperature. Using microwave plasma method to produce tungsten vanadium dioxide film is selecting V2O5 and W2O3 as precursors coated in the glass, then by microwave plasma enhanced synthesis method producing. The V1.96W0.04O5 colloids and producing process as follows:

1. A certain amount of V2O5 powder and W2O3 into the pot, stir, placed in a muffle furnace heated to 900 ℃ melted in an air medium.

2. After 15 minutes heat preservation, quickly putting solution in the certain amount deionized water cooling immediately, with vigorous stirring. Until create V1.96W0.04O5sol with stoichiometric ratio.

3. Using spin coating method, with 75% alcohol and deionized water repeatedly cleaned glass then coating prepared V1.96W0.04O5 sol in the glass.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Microwave Plasma Method Producing Tungsten Vanadium Dioxide (1)

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 16:31

The study found that vanadium dioxide will occurs first order phase transition in about 68 ℃, during the phase change process, vanadium dioxide (VO2) can occur reversible mutations in resistivity, magnetic, optical index, refractive index and transmissivity. Although VO2 is vanadium-titanium oxide of MIT characteristic’s which is the closest to room temperature, but its phase transition temperature higher than room temperature is still greatly hindered the application of VO2. It is possible to use doping method to change the temperature of VO2 to improve VO2 range of applications. Way of doping method has cation and anion doping. At present, there has many ways to doping VO2 such as sol - gel method, hydrothermal synthesis doping method, a sputtering doping method, metal organic chemical vapor deposition method and the microwave plasma method, and so on.

The experiment found that by microwave plasma method to produce VO2 film can reduce the VO2 powder phase temperature, the phase transition temperature can be lowered to 35 ℃. And using microwave plasma method to produce tungsten vanadium dioxide film is selecting V2O5 and W2O3 as precursors coated in the glass, then by microwave plasma enhanced synthesis method producing.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Points in Automotive Relay

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 16:09

Tungsten points play an important part in automotive relay. Magnetic system, contact system and restoring mechanism can be regarded as constituting an automotive relay. Tungsten points are applied in contact system; restoring mechanism is consisting of tension spring; magnetic system is composed of the core, the coil and the armature.

Due to relay is an automatic control device, the output will change by leaps and bounds when the input reaches up to a certain value.

Harsh conditions of tungsten points in automotive relay:

Bearing high load power;

Withstanding instable voltage;

Owning nice anti-seismic performance and better impact resistance;

Possessing corrosion resistance, tungsten points can resist the erosion of oil, salt, water, sand, dust, and others;

Temperature range: 40 ℃ ~ 125 ℃ around, if it is in other locations, its temperature range is between -40 ℃and 85 ℃.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Points Processing Requirements

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 16:07

People’s demand for tungsten points is increasing sharply with the development of automotive industry. Besides, they have strict processing requirements of tungsten points, whose processing requirements as described below:

High hardness;

Good impact toughness;

Smooth rod surface;

Small thermal expansion coefficient;

Excellent and stable arc-resistant performance;

There are no scratches and cracks in rod;

Section crystals fibers should be short;

With uniform and fine section crystals;

Owning better roundness, concentricity and flatness;

Having lower vapor pressure;

Possessing slower evaporation rate;

In order to satisfy people’s demand for tungsten points, the technicians of manufacturers have done lots of study on tungsten points’ physical and mechanical performance. In the producing process, they analyze the defects of tungsten points comprehensively, such as, splitting, brittle fracture, uniform section crystals size and others. What’s more, they have taken a series of measures to avoid the aforementioned problems.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Inspection Rules of Tungsten Contacts

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 15:12

Manufacturer's quality inspection department must inspect tungsten contacts and fill quality certificate to ensure that products conform to relevant standards.

Customers can test received tungsten contacts, if the test results does not conform to the mark of label, you can raise this problem to the manufacturer within three months, and after the two sides of mutual identification, if these tungsten contacts still not meet the requirements, the products failed.

Each batch of product sample in accordance with the following provisions:

The sample testing of the hardness, purity and the number of crystals of tungsten: Customers can directly make the sample preparation to measure tungsten contacts; or extracting a batch of products from the tungsten rods and sampling at its ¼. If the results fail, then double sampling retest. If there is still a failure, then the product failed.

In accordance with the provisions of GB / T 2828, check the size of the tungsten contacts, weld strength, appearance and the roughness of contact surface of tungsten contacts.

Specific check and accept programs can agree by manufacturers and customers.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Inserts Coating Architecture for Turning Operation (2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 15:09

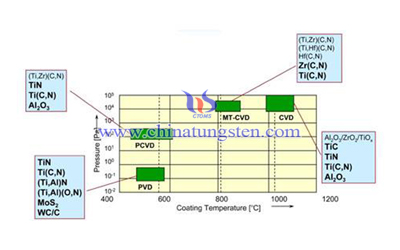

In the turning operation, coatings on the tungsten carbide inserts have been approved to make efforts in cutting forces reduction and extending the tool life to provide greater productivity. It should be noticed that, if these coating architectures could be well accepted, the tungsten carbide inserts are likely to make some significant cost reductions in this area, and to enable higher turning speeds and lower frictional losses during machining.

However, due to the technology limitation and inherent coating processes shortcomings, it still difficult to balance all the factors and which results, so far no single layer, multi-layer or multicomponent coating has been developed yet to meet satisfactorily meet all these requirements.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Inserts Coating Architecture for Turning Operation (1)

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 15:07

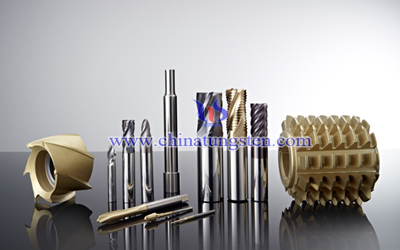

In actual practice, when employing coated tungsten carbide inserts on turning operations, there are several typical factors are likely to be involved, such as huge strains, high interface temperature, and newly generated chemically reactive surface. Specially, the interface temperature between tool and chip or tool and workpiece could be leveled up to 700-1250 ℃ and in the cutting zone the energy consumption due to the frictional losses varied from 25-35%.

In order to withstand such harsh condition, an ideal coating architecture of tungsten carbide inserts is required to meet high wear resistance, outstanding chemical stability, hot hardness, low friction and excellent adhesion to the substrate, as well as compressive residual stresses.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Limitation of Tungsten Carbide Inserts With CVD Coatings

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 15:06

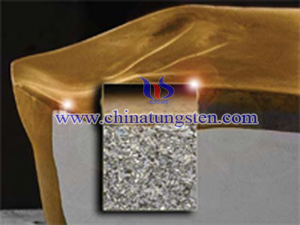

During the machining operations , the chemical vapour deposition (CVD) coatings as a traditional way have been widely applied in tungsten carbide inserts to enhance the tool life. Only in USA and Europe, there are over 60% of the cutting tools are applied by the CVD process.

However, the CVD coatings due to inherent disadvantages, have been examined several limitations which include the relative higher deposition temperature (950~1050℃) compared to other coating method, tensile stresses increasing between layers, inability to achieve thin coating layers as well as multicomponent coating layers, and due to the brittle formation, sometimes the adhesion of coating to the substrate is poor.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advantages of Tungsten Carbide Cutting Tools With PVD Coatings

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 15:04

It is known that since the using hard coating on tungsten carbide cutting tools, some huge improvements in productivity of machining operations have been achieved. The physical vapour deposition (PVD) method, which has several advantages over the chemical vapour deposition, has been employed for coatings like TiN, TiCN on tungsten carbide cutting tools.

The inherent advantages of PVD coatings over CVD ones have been revealed as the improvement of wear resistance of tungsten carbide cutting tools and the better performance in machining operations. In addition, since the coatings deposited by the PVD process, its film growth occurs at the atomic level, single or multiple thin layers of single or multicomponent structures could be employed on the tungsten carbide cutting tools, by using different reactive atmospheres and cathode materials.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Doped Vanadium Oxide Analysis (2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 14:55

After studies we found the difference between vanadium dioxide (VO2) films and tungsten-doped vanadium oxide films. Which are tungsten-doped vanadium oxide films has low phase transition temperature. But comparing XRD atlas of tungsten-doped vanadium oxide films which use microwave plasma with doping nitrogen to producing and VO2 found there has little different between both. Mainly tungsten doping is small and V4 + and W4 + ionic radius is very close. On the other hand VO2 by nitrogen doping can effectively reduce the phase transition temperature, when certain tungsten content, the phase transition temperature of the sample is the incorporation of the role of nitrogen. With the reduction of plasma reaction enhanced and doping nitrogen flow change, and the great changes of phase transition temperature indicating that nitrogen ions have been incorporated into the crystal lattice of V0.98W0.02O2-XNY undermine the VO2 The stability of the semiconductor, so that the phase transition temperature changes. The experiment found that when H2 flow of 10ml / min, N2 was 10ml / min, the reaction of the total power of 1kPa, the reaction time was 10min, the resulting thin film phase transition temperature can be reduced to 35 ℃.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com