Characterization of The Plasma Electrolytic Oxidation of Aluminium in Sodium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:12

Morphology, composition and microhardness of oxide coatings formed during DC plasma electrolytic oxidation (PEO) of aluminium in sodium tungstate were investigated. Oxide coatings were characterized by optical emission spectroscopy, AFM, SEM–EDS and XRD. Oxide coatings morphology is strongly dependent on process duration, while microhardness decreases with extended PEO time. The microdischarges characteristics were studied as well and it is shown that size of microdischarges becomes larger, while the surface density of microdischarge sites becomes lower, with increasing PEO time. Optical emission spectrum of microdischarges has several intensive band peaks caused by electronic transition in Al, W, Na, O, H atoms.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Spray Dryer

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:56

Spray drying is a wide applied process in liquid process shaping and drying industry. It can be used to transform solution, emulsion, suspension and paste liquid into powder and granular solids. When the finished particle size distribution, residual moisture content, density and particle shape must meet with precise standards, spray drying becomes an ideal method.

Ammonium metatungstate spray dryer principle: After filtering and heating, air goes into the dryer at the top of the air distributor, hot air spirals evenly into the drying chamber. Liquid goes through high-speed centrifugal atomizer at the top of the tower body (rotating) into a very fine vaporous liquid bead, contact with the hot air, being dried as finished product in a short time.

Ammonium metatungstate spray dryer feature:

1.High drying speed. After liquid be vaporous, superficial area increases, the instantaneous evaporation can be 95% -98% of the water in the hot air flow. It only takes a few seconds to finish drying process.

2.Finished product has good uniformity, flow ability and solubility. They are of high purity and quality.

3.Producing process is being largely simplified and it is easy to operate. It can dry the products which the moisture content is 90% in a very short time.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Preparing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:55

Ammonium metatungstate is a tungsten chemical in the form of highly soluble hydrated crystals, it is white or slightly yellow crystals which has no harmful components and slightly acidic. Due to its solubility in water, it can be used as raw material to produce tungsten trioxide.

Use ammonium paratungstate as raw material and heat to 220-280℃. After that it will lose ammonium and crystal water and transform into ammonium metatungstate. Continuously heat ammonium metatungstate to 600℃ until it loses all ammonium and crystal water, cool it down and crystallize, after spray drying it turns into yellow tungsten trioxide.

Ammonium metatungstate preparing tungsten trioxide is easy to operate, the finished product is of good uniformity. Tungsten trioxide can be used to made tungsten product and shielding matirials which is widely used in industry.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Patch Testing With Sodium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:54

Hard metal contains about 90% tungsten carbide. In an investigation of the skin of 853 individuals who are still working or had previously worked in hard metal manufacture. Sodium tungstate was in included in a patch test with a panel of substances from the environment of the employees. No allergic reactions to tungstate were found. However, irritant pustular reactions appeared in 2.0% of the patch tests. The pustular reactions were often reproducible.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Preparing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:53

Ammonium paratungstate (or APT) is a white crystalline salt of ammonium and tungsten, with the chemical formula (NH4)10(H2W12O42)·4H2O. Its shape is like sheet or needle.

Ammonium paratungstate being calcined in the air can produce tungsten trioxide. During the drying process, water was removed under about 100 degree Celsius. When temperature is above 240 degree Celsius, it turns into ammonium metatungstate. Under 300-350 degree Celsius, it becomes ammonium tungsten bronze. When temperature reaches 400 degree Celsius, hexagonal crystal tungsten trioxide comes into being. Finally triclinic crystal tungsten trioxide forms under 500 degree Celsius.

Calcination temperature and speed also affect the property of tungsten trioxide. The higher the temperature is, the larger the grain size of tungsten trioxide. The heating speed will cause the different superficial area of tungsten trioxide particle. Tungsten trioxide can be used to made tungsten product and shielding matirials which is widely used in industry.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Spray Dryer Existing Problems

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:51

Ammonium metatungstate spray dryer existing problems are listed as below:

1.Wall sticking phenomenon. Wet powder sticks in the drying chamber. The main reasons are: feeding amount exceed standard so it can not fully evaporate; before starting the drying process, the temperature of drying chamber is insufficient; after starting spraying, the feed speed is too fast.

2.Moisture content of product is too high. Low ventilating out temperature is the main reason that would affect the moisture content. Ventilating out temperature can be adjusted via feeding amount. So reduce the feeding amount will raise ventilating out temperature.

3.Finished product is of low purity. It is mainly because the air filtration is inefficient; incomplete cleaning of drying machine causes residual powder mixes up with finished product.

4.Grain size of finished product is too fine. This will affect ammonium metatungstate solubility and flow ability. It is mainly caused by the low solid content of liquid material.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Preparing Tungsten Trioxide by Microwave Calcination

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:49

The new process of calcination for ammonium paratungstate to tungsten trioxide by microwave was investigated.

The results of experiment show that the maximum decomposing rate of ammonium paratungstate is 96 .67 % after 4 min by microwave heating. In the new calcining process, the primary influnce factor is ammonium paratungstate' s weight, the secondary factors are time and microwave power. In this experiment range, the optimum conditions are that the microwave power is 650 W, the calcining time is 4 min, and the ammonium paratungstate′s weight is 10g.

Compared to the traditional method which will take two hours, the producing efficiency improves a lot. It is 1/30 of the original time. It embodies the advantages of microwave calcination. The finished product is of high purity, flow ability and good quality. Tungsten trioxide can be used to made tungsten product and shielding matirials which is widely used in industry.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

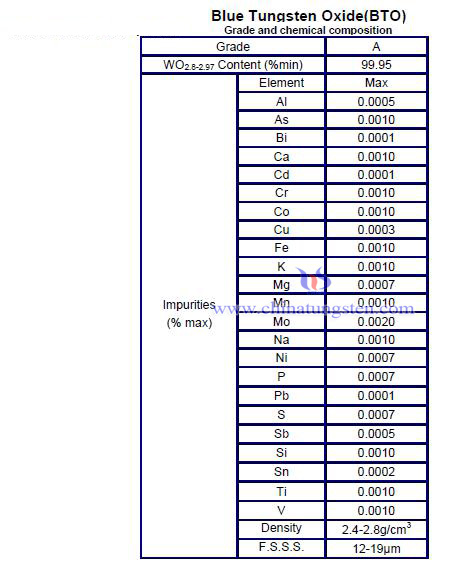

Blue Tungsten Oxide Chemical Composition

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:47

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparation of Aqueous Sols of Tungsten Oxide Dihydrate from Sodium Tungstate by An Ion-Exchange Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 14:21

Aqueous sols of tungsten oxide dihydrate (WO3·2H2O) were prepared from Na2WO4 by an ion-exchange method. An aqueous solution of Na2WO4 was let to flow through a glass column packed with protonated cation-exchange resin. The effluent, initially transparent, turned into an opaque viscous fluid (pale yellow) in a few hours, before yellow precipitate deposited to completion in three days. The precipitate was a mixture of a crystalline phase of WO3·2H2O and an amorphous phase, and the crystalline part could be separated from another by washing with deionized water and centrifuging. The gel of WO3·2H2O thus obtained consisted of platelike crystallite 25 nm thick and 42 nm wide as evaluated from the X-ray diffractometer (XRD) peaks, and could be dispersed well into deionized water to form a stable suspension of colloidal particles with a mean diameter of about 30 nm. The mean particle size as well as the crystallite size tended to increase gradually with the repetition of dispersion in water under ultrasonic wave agitation and gelling by centrifuging. On heating, the gel (WO3·2H2O) changed to the monohydrate (WO3·H2O) at 100 °C, which in turn changed to the anhydride (WO3) at 240 °C. Remarkably XRD patterns showed conspicuous preferred orientation of WO3·2H2O crystallites in (0 1 0) plane after the sol was centrifuged for a long time (10 h) and, upon dehydration, it was inherited by the dehydrated phases, resulting in the conspicuous orientation of WO3 crystallites in (0 0 1).

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Tc99 Generator

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 13:50

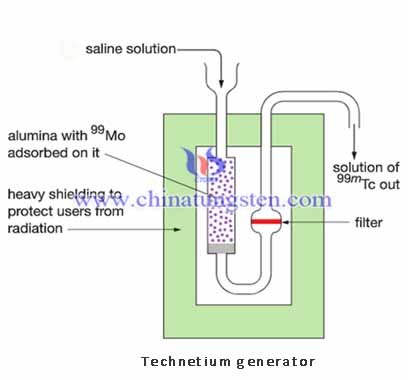

Due to its high density, excellent absorption behaviour against radiation and environmental friendly characteristics, tungsten alloy can be widely used to produce Technetium 99( Tc99) tungsten radiation shielding. Tc99 tungsten radiation shielding usually be used in nuclear medicine, which as the radiation shielding and container for Technetium 99m.

One of the commonly used radioactive materials in nuclear medicine is technetium 99 (Tc99). This is produced in a tungsten Tc99 generator, which contains a radioactive core, loaded with molybdenum 99 which decays to produce Tc99. This is mixed with sodium chloride and other chemicals before being injected into patients. The tungsten provides protection to the clinical staff handling tungsten Tc99generator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com