Main Factors on Quality of Tungsten Points (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 15:57

2. Inappropriate control of tungsten blanks granule can have an influence on the quality of tungsten points

Coarse grains, fine grains and other different crystalline existing in the sintered tungsten bar at the same time, to a large extent, this is due to uneven mixing or the inappropriate ratio of particle size of tungsten powder. Among which fine grains will be too burning, it will have an impact on processing performance of tungsten bars, and ultimately it will affect the performance of tungsten points.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Main Factors on Quality of Tungsten Points (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 15:55

1. Metallurgical defect of tungsten blanks can have an effect on the quality of tungsten points

Metallurgical defects of tungsten blanks refer mainly to:

In the smelting process, the inside part of tungsten blanks form defects, such as, slag inclusions, pores and so on. What’s more, some of these defects are difficult to preclude even in pressing process. For example, in the crystal boundary, there is the distribution of Ni, Fe and other impurities or compounds. The combination of grain surface is damaged due to these impurities, pores and other defects. So its metal bases are not continuous, it will result in the generation of cracks or tears of tungsten blanks in the process, and eventually lead to its final product --- tungsten points’ split and brittleness.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Scheelite/Calcium Tungstate-III

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 15:31

Physical characteristics of scheelite/calcium tungstate:

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online -www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Scheelite/Calcium Tungstate-II

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 15:28

Powellite, CaMoO4, is isostructural with scheelite which is why it forms similar crystals. The two minerals form a series in which the tungsten of scheelite is substituted for by the molybdenum of powellite. Powellite fluoresces a yellow color while scheelite fluoresces a bright blue under short wave ultraviolet light. Of course since molybdenum can substitute for tungsten, some scheelite specimens will show a yellow fluorescence.

The crystals of scheelite can look like fluorite octahedrons which can also fluoresce. However, fluorite has perfect octahedral cleavage and a lower luster. Massive scheelite has often been mistaken for massive quartz, but then the fluorescence of scheelite is a dead giveaway.

Many prospectors for scheelite have made good use of scheelite's typically bright blue fluorescence by searching for scheelite deposits by night with ultraviolet lamps. Many old mines have even been reopened after examination of the mine shafts with ultraviolet lamps have proven that the ore is not quite yet exhausted.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online -www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Scheelite/Calcium Tungstate-I

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 15:25

Chemistry: CaWO4, Calcium Tungstate

Class: Sulfates

Subclass: Tungstates

Uses: An important source of tungsten, rarely cut as gemstones and as mineral specimens.

Scheelite is an important ore of tungsten which is a strategically important metal. Scheelite is named for the discoverer of tungsten, K. W. Scheele. Although most of the world wide production of tungsten comes from the mineral wolframite, scheelite is especially abundant in the US and provides the United States with most of its supply.

Scheelite is a popular mineral for collectors. It forms perfect tetragonal dipyramidal crystals that look very much like octahedrons. These pseudo-octahedral crystals are sometimes truncated with minor pyramids, but only on the top and/or bottom points of the crystal; giving evidence of their true symmetry. Other minerals that form pseudo-octahedral crystals similar to scheelite include wardite, anatase and powellite.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online -www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Chip Formation

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 14:33

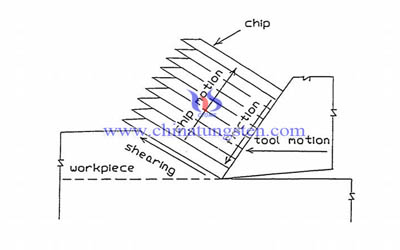

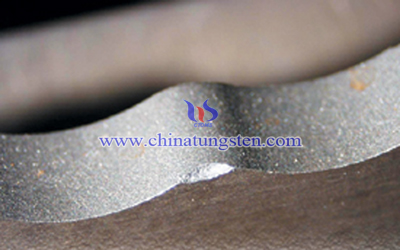

When tungsten carbide cutting tools are employed in machining operation, the entire process of chip formation comprises primary shear, secondary shear and fracture process.

The primary shear of chip formation process is also referred to the workpiece material’s plastic deformation, which is severe and could be found in front of the cutting edge where the chip body is delineated from a large amount of workpiece material. For the secondary shear, the chip slides over the rack face of the tungsten carbide tool. In the final separation stage, a fracture process takes over.

It is shown that the relative ease of the chip formation process is determined by the workpiece material’s flow properties. In addition, besides the existing conditions, the varied chips’ size and shapes are also under the control of factors like workpiece ductility, inclusion characteristics and etc..

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micromechanisms of Tungsten Carbide Inserts’ Tool Wear (3)

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 14:33

Chipping

It is known that during the machining operation, when sudden loads or thermal shocks occur, there is a potential for the tungsten carbide inserts to suffer from severe damage due to cracking or chipping.

In some comprehensive model, the researchers have described in details, the toughness of tungsten carbide is strongly influenced by the binder composition. It has been pointed out that the toughness of WC-Co is superior to that of TiC-Ni, in addition, the problem of tungsten carbide inerts failure due to chipping is particularly severe for alumina based tools, but with zirconia additions, the toughness of tungsten carbide tool could be markedly improved.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micromechanisms of Tungsten Carbide Inserts’ Tool Wear (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 14:33

Abrasive Wear

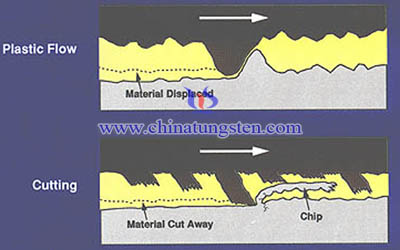

The tungsten carbide inserts’ abrasive wear, as one of the major mircromehanisms, which is referred to the wear that caused by the tool material removal. It has been pointed out that the removal of tool material is result of scoring action of hard phase particles or the workpiece material’s inclusions. In addition, the abrasive wear process can be identified as microchipping of the tool because of rapid increases in force exerted over a localized area.

Specially, in practice use, the details have been described by the researchers, there is a clear correlation between increased tool wear and increased amounts of abrasive particles in the workpiece.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micromechanisms of Tungsten Carbide Inserts’ Tool Wear (1)

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 14:32

Under a certain cutting condition, it could be examined that the tungsten carbide inserts’ tool wear is result of variety of mechanisms, and each one of which owns ability to dominant wear mechanism. In general, for the tungsten carbide inserts, the main micromechanisms of tool wear include, adhesive wear, abrasive wear, dissolution wear and oxidation wear, corrosive wear, plastic dominated wear,chipping.

Adhesive Wear

During the chip formation process, it has been pointed out that the chips would slide over the rack face of cutting tool, and it cleans the surface to form an oxides and contaminants free area. But it should be noticed that, for these surface, there is a potential to become one continuous adhesive junction, and when this junction is broken due to the flow of chips, some part of the tool material is removed. It has been found that, especially during steel machining, with more brittle tungsten carbide cutting tools, the adhesive junction is able to result in the whole tungsten carbide particle being plucked from the tool.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Preparation-Neutralization Method

- Details

- Category: Tungsten Information

- Published on Thursday, 02 July 2015 14:28

Ammonium metatungstate, also known as AMT, is a tungsten chemical in the form of highly soluble hydrated crystals, solubility is 303.99/loogH:O when 20℃, aqueous fairly stable. It is white or slightly yellow crystals which has no harmful components and slightly acidic.

Neutralization method with secondary ammonium metatungstate and Nitrate as the raw material purchase ammonium metatungstate: secondary ammonium metatungstate deionized water and ammonium citrate with WO3 12%~ 30% concentration of slurry. According to =1:20: nitrate ammonium paratungstate by adding 3% ~ 5% of dilute nitric acid to ammonium paratungstate slurry, control ratio of solid to liquid 1: (3 ~ 4), the Ph value of 2 ~ 4, heating and dissolving solution, the relative density of 1.18 ~ 1.20, heating to 80 ~ 90 ℃, constant temperature and constant volume control Ph value, the stirring reaction for 4H hours, aging, concentrating the supernatant to WO3 content is about 50-, filtration to remove insoluble, liquid concentration, cooling crystallization, continue to 80 ℃ drying.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com