Pharmacokinetics of Sodium Tungstate in Rat and Dog: A Population Approach

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 16:12

Sodium tungstate has been found to correct hyperglycemia in insulin- and noninsulin-dependent models of diabetes when administered in drinking fluid with a low degree of toxicity; thus, it provides a potential treatment for diabetes. In the present report, pharmacokinetic studies with sodium tungstate were carried out in the Sprague-Dawley rat and beagle dog. This drug was administered either i.v. (8.97 mg/kg in rat; 25 and 50 mg/kg in dog) or orally in the form of solution (35.9 and 107.7 mg/kg in rat; 25 and 50 mg/kg in dog). Tungsten was quantified using an inductively coupled plasma method. Pharmacokinetic parameters were estimated using a population approach. Sodium tungstate followed first order kinetics, and plasma concentration-versus-time data were adequately described by a two-compartment model. In rat, bioavailability was high (92%), whereas it was lower in dog (approximately 65%). The total volume of distribution expressed by unit of body weight was much higher when the animal was smaller (0.46 l/kg in rat versus 0.23 l/kg in dog). The total body clearance normalized by weight, 0.19 l/h/kg in rat versus 0.043 l/h/kg in dog, changed as for the volume of distribution. The elimination half-life was two times higher in dog (approximately 4 h) than in rat (approximately 1.7 h). In the range of 35.9 to 107.7 mg/kg after oral administration in rat and 25 to 50 mg/kg after oral and i.v. administration in dog, tungsten plasma concentrations increased in proportion to dose.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Point Properties

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:55

Tungsten point properties:

Nice melt resistance;

High purity:≥99.95%;

Hardness: 71 - 74HRA;

Weld strength:≥ 83MPa;

Excellent wear resistance;

Good arc-erosion resistance;

High capability of breaking current;

Size deviation is permitted: dh ± 0.05mm;

The number of crystals is more than 10,000PCS / mm2;

Less transfer consumption due to electro-thermal effect;

Density range is available between 19.1g / cm3 and 19.3 g / cm3;

The carbon content of nail seat base:≤0.10% of the low-carbon steel;

Welding purity of tungsten copper alloy:≥99.95%. (Products are available according to your requirements)

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Point

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:51

Tungsten point is an important component which is used for the on-off control of circuit in the switch.

Performance of tungsten products:

Having wear-resistance;

With arc-erosion resistance;

Possessing nice melting resistance;

Owning high capability of breaking current;

Due to electro-thermal effect, its transfer consumption is less.

Tungsten point application:

Tungsten point is widely applied in industry, agriculture, science and technology and defense fields, such as cars, relays, sirens, and Magneto, motorcycles and communications machine.

Technological requirements of tungsten point: With the development of automotive industry, people are stricter with the processing requirements of the tungsten point. They require the rod of tungsten point: own smooth surface, good flatness, nice concentricity and better roundness; crystals in section are fine and uniform and its fibers are short; without cracks.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Anodic Film Growth on InP in Sodium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:42

Anodic film growth on InP and the wider implications to alloys have been examined, with the aim of probing film composition to gain insight into the ionic transport processes responsible for duplex film formation. For anodizing at relatively high efficiency, the anodic film reveals an outer indium-rich layer, essentially free of phosphorus species, and an inner layer containing both indium and phosphorus species. Growth of such films, on a co-operative transport basis, leading to amorphous film formation, can be explained by the faster outward migration of indium species relative to phosphorus species. The inner layer would then be composed of appropriately arranged In–O and P–O units. However, such an arrangement is difficult to reconcile with the X-ray photoelectron spectroscopy data, which suggest the presence of phosphorus in the form of P2O5, PO43−, PO3− and polyphosphate species. In order to explain fully the transport process for film growth and to understand film composition, further studies using marker and tracer experiments are essential.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

TiN/TiC Coated Tungsten Carbide Inserts Flank Wear

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:36

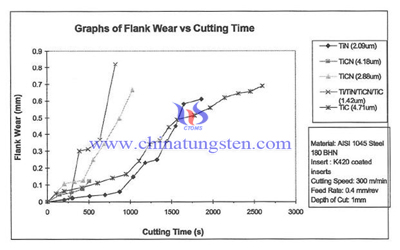

Flank wear is referred to the wear eroded by the portion of the tool in contact with the finished workpiece, which is an important factor to examine the life of coated tool.

In the research , if the TiC coated tungsten carbide inserts’ coating thickness is 4.71um while the TiN coating ones having a thickness of 2.09um are put into the turning operations, it could be observed that the flank wear growth in inserts having TiN coating appears to be much faster till the tool failure.

Besides the thickness issue which maybe likely to cause the rapid wear growth of TiN coated inserts, the other factors such as temperature and heat are identified to have a possibility to be attributed to faster failure of tool life. Since turning operations typically involve with high interface temperature and a large amount of heat and high speed, which may cause reduction of coating hardness and hence resultant of low wear resistance. In addition, the large heat would soft the substrate and cause cutting edge thermal deformation, which also adds to the failure of coated tungsten carbide inserts.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

TiN/TiC Coated Tungsten Carbide Inserts Crater Wear

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:35

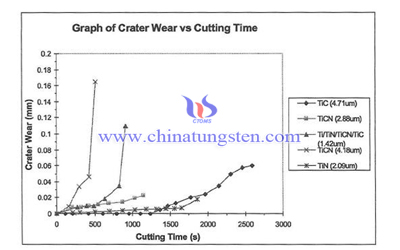

Crater wear is the wear caused by cutting chips contact with cutting tool erodes the rake face.It is known that the crater wear is normal for tool wear, and until it become serious enough to cause a cutting edge failure, it does not largely affect the use of a tool. And for which, the crater wear could be a factor to examine tool life.

In the turning operation test, when the TiC coated tungsten carbide inserts’ coating thickness is 4.71um while the TiN coating ones having a thickness of 2.09um, as the growth of the crater wear, the tungsten carbide inserts with TiC coating appears to have a relatively longer tool life before tool collapses. In addition, it could be examined that until 1250 seconds there is scarcely any growth of carter wear in TiC coated tungsten carbide insert, and after that a slow growth of this wear till tool failure. Interestingly, a similar growth of carter wear in tools having TiN coating is identified, although it has a relatively low tool life .

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Cutting Fluids on Tungsten Carbide Tipped Tools (2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:32

Since the tungsten carbide tipped tool’s condition is a vital factor to maintain consistent quality of cutting effect in metal cutting process, it is necessary to match the tipped tool with cutting fluids to optimum the metal removal rate and extend the tool life.

In general the cutting fluids are designed to lubricate and cool the cutting chip, as well as tool interface. It could also help the tungsten carbide tipped tool to reduce the tool wear due to friction and abrasion, which in addition to improve the finishing of the workpiece surface. There are several approaches for the cutting fluids to reach the chip tool interface, like capillary action by which the fluids diffuse through the highly distorted structure of metal.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Cutting Fluids on Tungsten Carbide Tipped Tools (1)

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:32

High material removal rate, good surface finish and low tool wear are the three major requirements during the machining processes. As an important and easy way to achieve these targets, the correct selection and use of cutting fluids could make an effort to enhance the performance of tungsten carbide tipped tools.

The effect of some cutting fluids include paraffin, soluble oil on the flank wear of tungsten carbide tipped tools to machine aluminum, brass workpieces could be indicated as follows, in general the tungsten carbide tipped tools exhibit better flank wear resistant compared other materials, and the soluble oil with 20% concentration is likely to offer smallest flank wear, which is 0.002mm, for machining aluminum workpiece among the cutting fluids. In addition, when tungsten carbide tipped tool employed by the soluble oil is observed to have a capability to provide a longer tool life as well as better surface finish for all workpieces.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

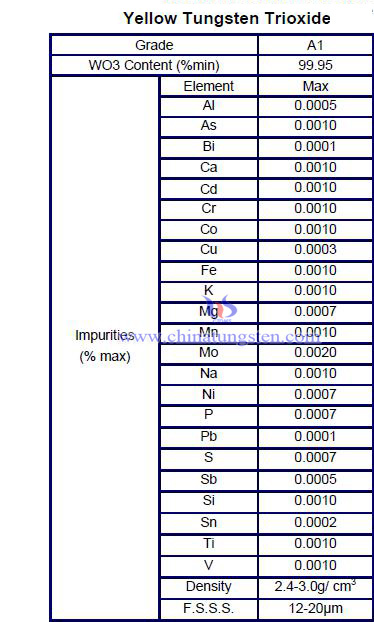

Yellow Tungsten Trioxide Chemical Composition (2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:24

Packing: in iron drum with double inner plastic bag of 50kgs or 200kgs net each.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Yellow Tungsten Trioxide Chemical Composition (1)

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:20

Packing: in iron drum with double inner plastic bag of 50kgs or 200kgs net each.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com