Applications of Tungsten Alloy Counterweights in Consumer Electronics

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2025 14:20

In the consumer electronics field, tungsten alloy counterweights play a significant role in enhancing product performance, optimizing user experience, and meeting green design requirements due to their high density, high strength, and excellent corrosion resistance. Consumer electronic products such as smartphones, smartwatches, earphones, and game controllers have high demands for weight distribution, space utilization, and electromagnetic compatibility, making tungsten alloy counterweights, with their unique physical properties, an ideal choice for compact designs and premium features.

Applications of Tungsten Alloy Counterweights in Industrial Equipment

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2025 14:16

In the industrial equipment field, tungsten alloy counterweights, due to their high density, high strength, excellent corrosion resistance, and wear resistance, serve as key components in dynamic balance systems for CNC machine tools, industrial robots, and other heavy equipment. Tungsten alloy counterweights optimize weight distribution, effectively reducing vibration and mechanical stress, improving machining accuracy, equipment stability, and service life.

Applications of Tungsten Alloy Counterweights in Precision Instruments

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2025 14:13

Precision instruments require high accuracy, stability, and durability in counterweights, and tungsten alloy counterweights, with their high density and small volume, have become the preferred material in this field.

Applications of Tungsten Alloy Counterweights in Medical Equipment

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2025 14:09

In the medical equipment field, tungsten alloy counterweights play a critical role in radiotherapy devices, diagnostic instruments, and high-precision surgical instruments due to their high density, non-toxicity, non-radioactivity, and excellent radiation shielding capabilities.

Applications of Tungsten Alloy Counterweights in Automotive Field

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2025 14:06

Tungsten alloys, with their high density (17-18.5 g/cm³), high strength (tensile strength up to 900-1200 MPa), and excellent corrosion and wear resistance, serve as critical components for optimizing power transmission, stability, and efficiency in automobiles.

Applications of Tungsten Alloy Counterweights in Aerospace

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2025 14:03

In the aerospace field, high-density tungsten alloy counterweights, with a density of 17-18.5 g/cm³, serve as key components for achieving equipment balance, space optimization, and performance enhancement. Compared to traditional materials like steel or lead, tungsten alloys significantly reduce volume under the same weight, not only optimizing structural layout but also reducing air resistance, thereby improving the fuel efficiency and overall performance of aircraft.

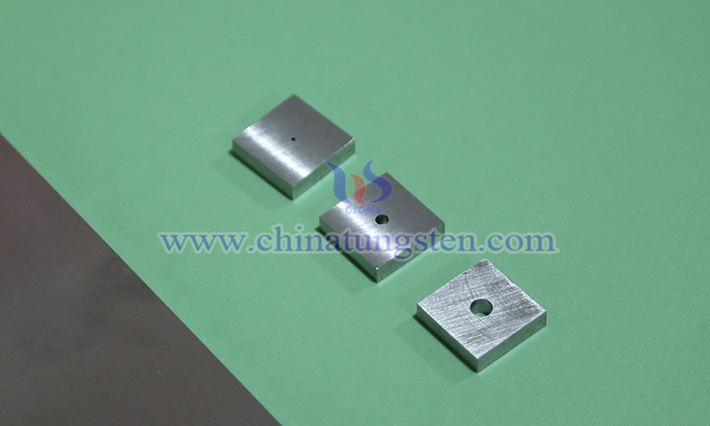

What Is Tungsten Alloy Shielding Component?

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2025 13:56

With the rapid development of industries such as nuclear energy, medical imaging, and industrial inspection, the demand for efficient and environmentally friendly shielding materials is increasingly urgent. Tungsten alloy shielding components, as high-performance radiation protection elements, are gradually replacing traditional lead-based materials due to their exceptional shielding efficiency, mechanical strength, and eco-friendly properties, becoming the preferred solution in radiation protection. For tungsten alloy shielding components, please contact CTIA GROUP LTD Online: sales@chinatungsten.com, 0592-5129595.

Applications of Tungsten Alloy Counterweights

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2025 13:53

CTIA GROUP LTD tungsten alloy counterweights are renowned for their high density, excellent mechanical properties, corrosion resistance, and processing flexibility.

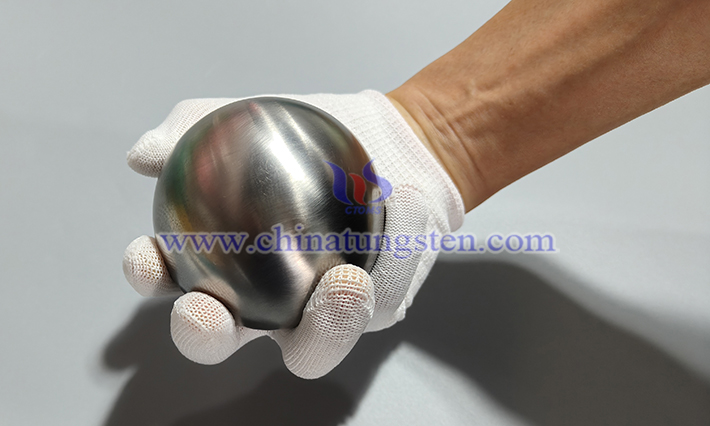

CTIA GROUP Tungsten Alloy Rehabilitation & Fitness Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 October 2025 16:58

CTIA GROUP Tungsten Alloy Rehabilitation & Fitness Balls — Technological Metal, Embodying the Beauty of Strength, Health & Balance

I. CTIA’s Tungsten Alloy Rehabilitation & Fitness Balls

What Is Tungsten Alloy Weights?

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2025 14:10

In modern technology and industrial fields, high-precision weight measurement is a critical factor in ensuring quality and driving innovation. From microscopic chemical analysis in laboratories to quality inspections on industrial production lines, accurate weight data serves as the foundation for scientific discoveries and production efficiency. In these high-precision scenarios, tungsten alloy weights stand out as essential measurement tools due to their exceptional performance and stability.

sales@chinatungsten.com

sales@chinatungsten.com