Surface Quality Control of Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 19:23

Tungsten carbide balls, known for their high hardness, wear resistance, and excellent mechanical properties, are widely used in bearings, valves, grinding media, and other fields. Surface quality directly affects their performance and lifespan, making surface quality control a critical aspect of the production process. Effective control involves material selection, processing techniques, inspection methods, and quality management.

Surface Strengthening Technologies for Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 19:19

Due to their high hardness, wear resistance, and corrosion resistance, tungsten carbide balls are widely used in bearings, valves, seals, and other fields. Surface strengthening technologies are critical for further enhancing their performance. Below is a brief overview of several commonly used surface strengthening technologies for tungsten carbide balls.

High-Temperature Resistant Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 19:14

Tungsten carbide balls are high-performance spherical materials formed by sintering tungsten carbide (WC) powder with cobalt (Co) or other metal binder powders at high temperatures. The core component, tungsten carbide, offers extremely high hardness, while binders like cobalt provide toughness.

Surface Polishing Technology for Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 19:10

Tungsten carbide balls, known for their high hardness, wear resistance, and excellent mechanical properties, are widely used in precision bearings, valves, grinding media, and other fields. Surface polishing is a key process to improve their performance, significantly reducing surface roughness, enhancing dimensional accuracy and surface finish, thereby extending service life and improving operational efficiency.

Tungsten Carbide Balls Polishing Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 19:04

The polishing process for tungsten carbide balls is mainly used to enhance their surface finish, dimensional accuracy, and sphericity. It is typically applied in fields such as precision bearings, valves, and instruments. The following provides a detailed explanation of the tungsten carbide ball polishing process, covering the main steps, methods, and precautions:

The Relationship between Hardness and Wear Resistance of Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:57

The hardness of tungsten carbide balls is a key determinant of wear resistance. High hardness generally results in excellent wear resistance, but a balance between hardness and toughness must be achieved by adjusting the composition, grain size, and binder phase ratio to suit different operating conditions. In practical applications, wear resistance is also affected by friction conditions, environment, and the mating material.

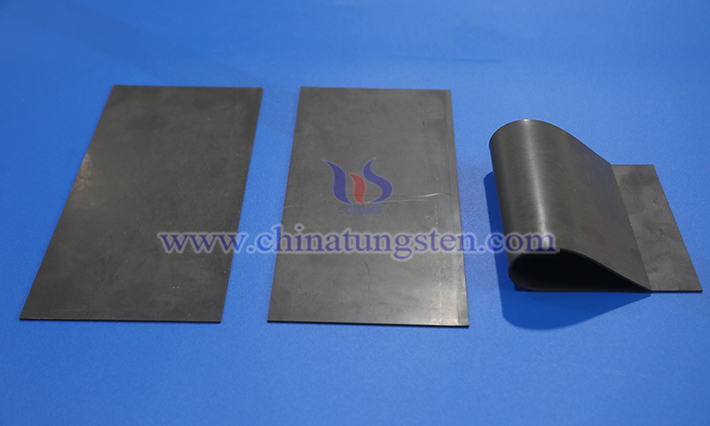

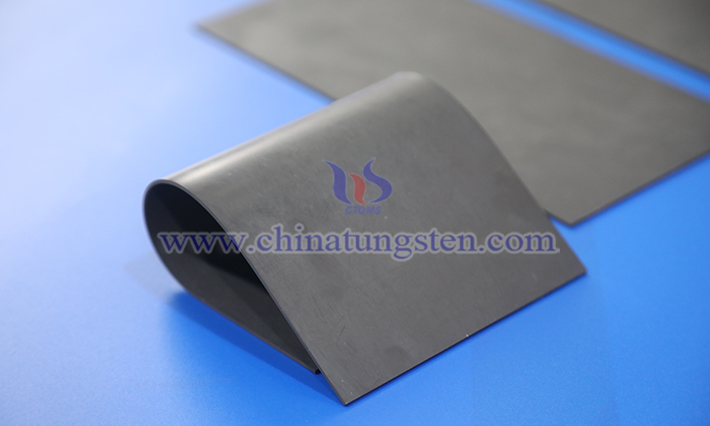

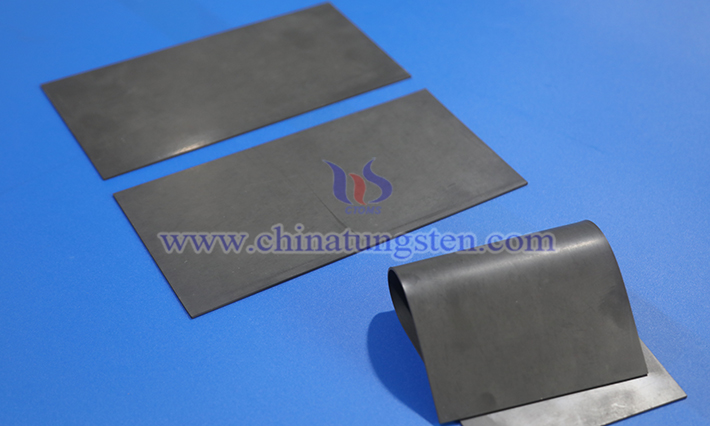

High-Temperature Performance of Tungsten Resin

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:48

Tungsten resin is a novel composite material whose high-temperature performance primarily depends on the type of resin matrix, the properties of tungsten powder, and the preparation process. Common resin matrices include polyethylene-based resins, epoxy resins, polyurethanes, and specialty resins.

Applications of Tungsten Resin in Golf Clubs

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:45

Tungsten resin, due to its high density, excellent processability, and environmental friendliness, is widely applied in golf club manufacturing applications, primarily for counterweight components such as head weights or shaft weights to optimize the center of gravity, enhance swing stability, and improve ball-strike performance.

Preparation Methods of Tungsten Resin

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 18:43

CTIA GROUP LTD tungsten resin is a composite material made from tungsten powder and a resin matrix (such as polyethylene, epoxy resin, or other polymer materials), widely used in radiation shielding, fishing gear, and biomimetic materials. The preparation methods for tungsten resin vary depending on the matrix type, tungsten powder content, and application requirements, with common techniques including injection molding, compression molding, press-sintering, and high-speed mixing-calendering.

Magnetic Properties of Tungsten-Nickel-Iron Alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 15:16

Tungsten-nickel-iron alloy (W-Ni-Fe alloy), also known as high-density tungsten alloy, is a composite material with tungsten as the primary component and nickel and iron as binding phases. Typically containing over 90% tungsten, with the remainder a mixture of nickel and iron (e.g., typical ratios like 95W-3Ni-2Fe or 93W-5Ni-2Fe), this alloy is valued for its high density (16.5-18.5 g/cm³), high strength, corrosion resistance, and good machinability, finding wide use in defense, aerospace, medical, and industrial fields. The question raised by users concerns whether this alloy exhibits magnetic properties.

sales@chinatungsten.com

sales@chinatungsten.com