Performance Comparison of Tungsten Resin and Lead

- Details

- Category: Tungsten Information

- Published on Monday, 13 October 2025 18:31

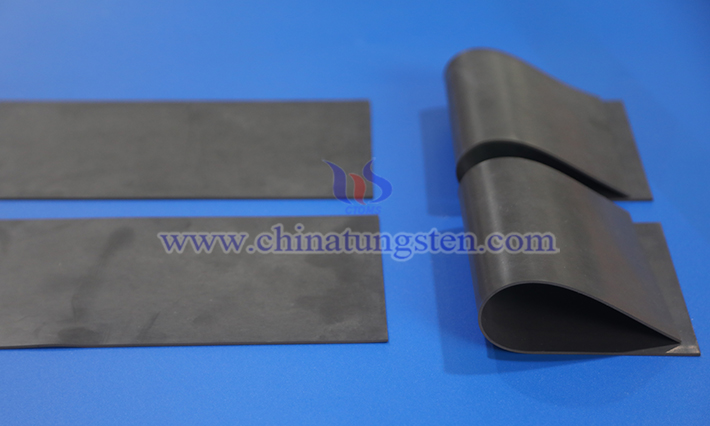

Tungsten resin is a composite material made from high-purity tungsten powder and polymer resin, renowned for its high density, eco-friendliness, and processing flexibility. Lead, as a traditional high-density material, has long been used in industrial, medical, and sports applications due to its low cost and good ductility. However, with growing concerns over environmental regulations and health safety, tungsten resin is increasingly replacing lead.

Applications of Tungsten Resin in Sports Equipment

- Details

- Category: Tungsten Information

- Published on Monday, 13 October 2025 18:29

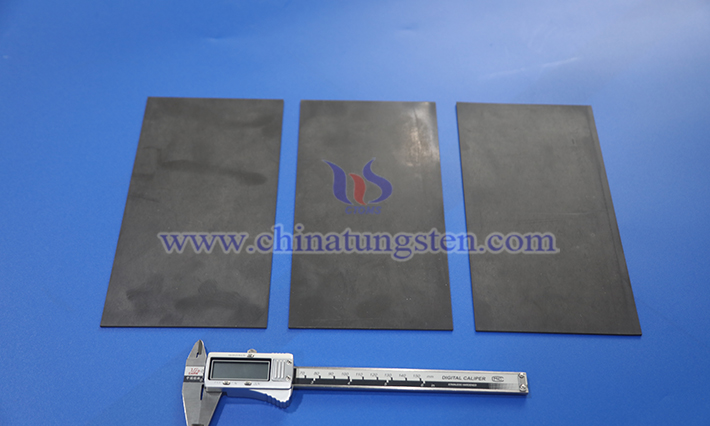

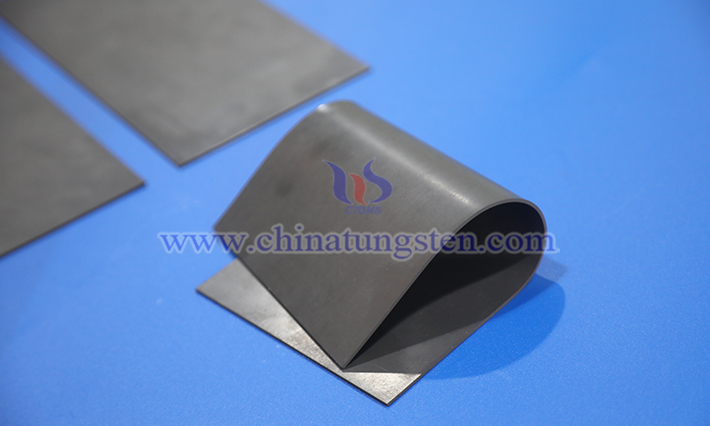

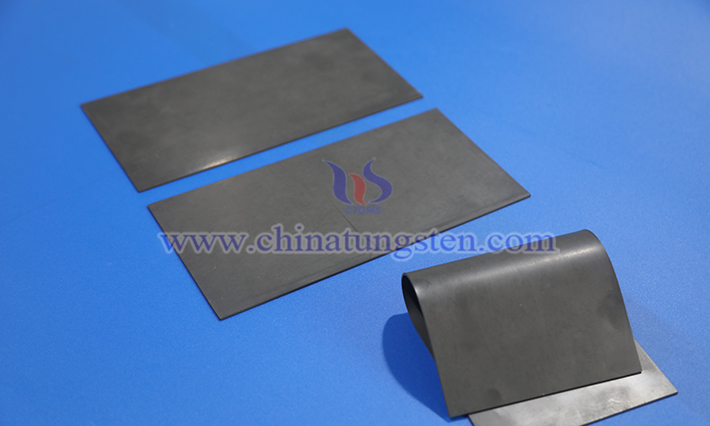

Tungsten resin (Tungsten Resin) is a composite material made from high-purity tungsten powder combined with various resins (such as polypropylene, polyurethane, or thermoplastic materials).

Applications of Tungsten Resin in the Nuclear Industry

- Details

- Category: Tungsten Information

- Published on Saturday, 11 October 2025 16:53

As an advanced composite material, tungsten resin is increasingly valued in the nuclear industry. This material combines the unique properties of tungsten with the flexibility of resin, forming an efficient and reliable solution suitable for nuclear environments requiring high protection and durability.

Applications of Tungsten Resin in the Medical Field

- Details

- Category: Tungsten Information

- Published on Saturday, 11 October 2025 16:51

As a novel composite material, tungsten resin is increasingly widely used in the medical field. This material combines the excellent properties of tungsten with the flexibility and ease of processing of resin, creating an efficient and environmentally friendly solution.

What Are the Uses of Tungsten Resin?

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 September 2025 17:24

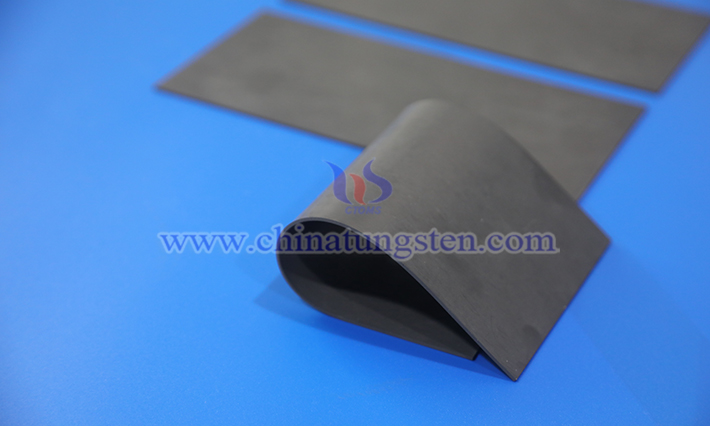

Tungsten resin, leveraging its high density, non-toxicity, radiation shielding capability, and processing flexibility, finds wide-ranging uses in medical, defense, industrial, civilian, and emerging technology fields.

What Are the Characteristics of Tungsten Resin?

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 September 2025 17:22

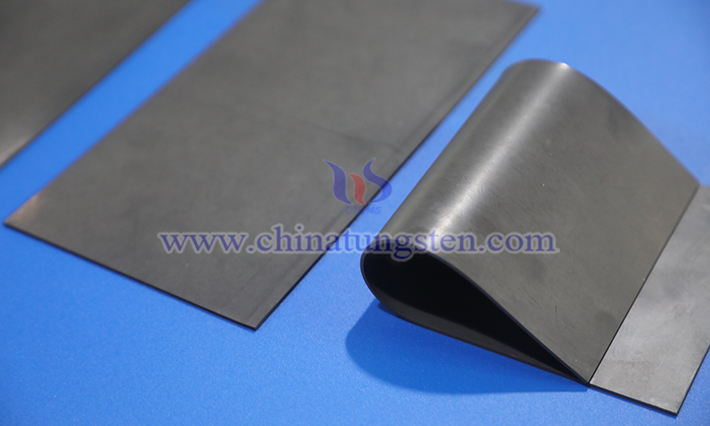

Tungsten resin is a composite material made by mixing high-purity tungsten powder with polymer resins (such as epoxy, polyurethane, or polyethylene). It is widely used in defense, medical, industrial, and environmental fields, thanks to its unique physical, chemical, and processing characteristics.

What Is Tungsten Resin?

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 September 2025 17:20

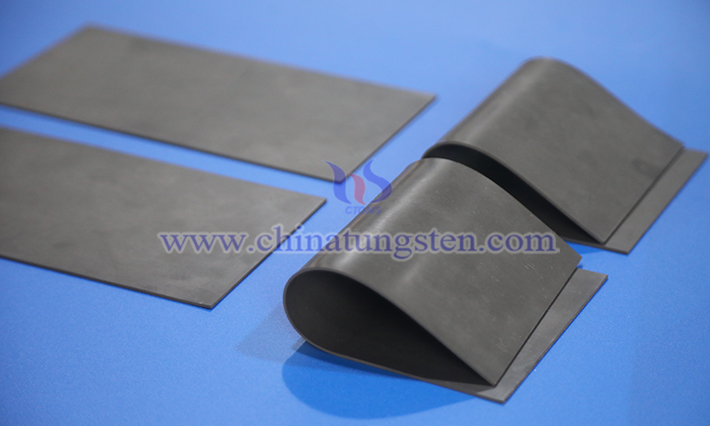

Tungsten resin, also known as tungsten polymer composite material or tungsten-filled resin, is a novel polymer composite material. It is primarily made by mixing high-purity tungsten powder with polymer resins (such as epoxy, polyurethane, or thermoplastic resins) in specific ratios and through specialized processes. This material combines the unique physical properties of tungsten (such as high density and radiation resistance) with the processing flexibility of resins, resulting in a non-toxic, environmentally friendly, and easily moldable material.

Application Fields of Tungsten Alloy Fasteners

- Details

- Category: Tungsten Information

- Published on Friday, 26 September 2025 15:55

In contemporary industrial connection systems, tungsten alloy fasteners serve as high-performance connecting elements, playing a pivotal role and regarded as core components in materials engineering. Their exceptional performance stems from the inherent properties of tungsten and the optimization of other metal elements. Firstly, their high density ensures efficient weight distribution and connection stability within a limited volume.

Classification of Tungsten Alloy Fasteners (Part Three)

- Details

- Category: Tungsten Information

- Published on Friday, 26 September 2025 15:49

Tungsten alloy fasteners, with their high strength, high-temperature resistance, and corrosion resistance, play a crucial role in high-demand fields such as aerospace, nuclear industry, and precision machinery.

Classification of Tungsten Alloy Fasteners (Part Two)

- Details

- Category: Tungsten Information

- Published on Friday, 26 September 2025 15:32

Tungsten alloy fasteners, owing to their excellent physicochemical properties, are designed as specialized connectors to meet the demands of specific working conditions. Based on functional requirements, the classification of these components falls into three major categories—high-temperature resistance, corrosion resistance, and high precision—and each category has been optimized through special processes to adapt to extreme environments and high-reliability scenarios.

sales@chinatungsten.com

sales@chinatungsten.com