What Is Tungsten Alloy Shielding Component?

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2025 13:56

With the rapid development of industries such as nuclear energy, medical imaging, and industrial inspection, the demand for efficient and environmentally friendly shielding materials is increasingly urgent. Tungsten alloy shielding components, as high-performance radiation protection elements, are gradually replacing traditional lead-based materials due to their exceptional shielding efficiency, mechanical strength, and eco-friendly properties, becoming the preferred solution in radiation protection. For tungsten alloy shielding components, please contact CTIA GROUP LTD Online: sales@chinatungsten.com, 0592-5129595.

I. Definition and Basic Properties of Tungsten Alloy Shielding Components

CTIA GROUP LTD tungsten alloy shielding components are radiation protection elements made from high-density tungsten-based alloys, primarily used to absorb and attenuate X-rays, gamma rays, and neutron radiation. Their core lies in the unique physical properties of tungsten (tungsten content typically exceeding 90% of total weight): tungsten's high atomic number and density enable it to effectively block the penetration of high-energy radiation. Unlike the brittleness of pure tungsten, tungsten alloys, enhanced with other metal elements, form a high-strength, easily processable composite material. This allows shielding components to offer excellent protective performance while being manufactured into complex shapes such as collimators, container lids, or shielding plates.

To improve mechanical properties and processability, tungsten alloys are typically alloyed with elements like nickel, iron, or copper. Nickel: As a key binder, it enhances tungsten's toughness and ductility, forming a uniform solid solution that reduces brittleness, facilitating the machining of complex shielding shapes; it also improves corrosion resistance, extending the lifespan of shielding components in humid environments. Iron: Increases alloy strength, with nickel-iron compounds evenly distributed at grain boundaries to form a continuous reinforcement network, effectively enhancing resistance to deformation under high radiation or mechanical impact, ensuring structural stability; iron's low cost helps control manufacturing expenses, making it suitable for large-scale industrial applications. Copper: Improves thermal and electrical conductivity, enhances non-magnetic properties, making it ideal for MRI equipment and other magnetically sensitive scenarios; copper also boosts oxidation resistance, preventing degradation of shielding components in high-temperature radiation environments.

Tungsten alloy shielding components exhibit a range of exceptional properties that make them highly effective for radiation protection, including high density for small volume and high shielding efficiency, ideal for space-constrained scenarios like collimators; excellent shielding ability with significant attenuation of X-rays and gamma rays, serving as a lead-free alternative suitable for nuclear medicine and industrial inspection; high mechanical strength that is impact-resistant and deformation-resistant, ensuring durability during transportation and long-term use; corrosion resistance with oxidation and chemical corrosion resistance, making them suitable for humid or acidic environments such as marine nuclear engineering or chemical labs; non-magnetic properties that avoid interference with sensitive instruments in MRI and electromagnetic equipment; environmentally friendly and non-toxic characteristics that reduce environmental and health risks, promoting green radiation protection technology; and processing flexibility that allows for the creation of complex shapes, supporting custom designs like multi-leaf collimators to meet personalized protection needs.

II. Classification of Tungsten Alloy Shielding Components

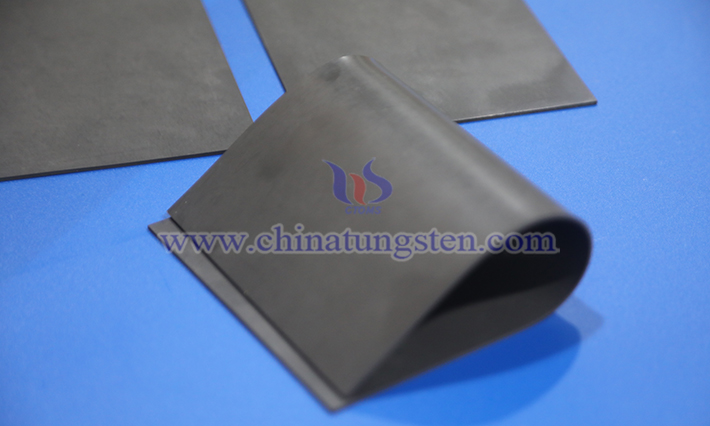

Tungsten alloy shielding components are categorized into three main types based on composition, each offering unique characteristics and application scenarios: the Tungsten-Nickel-Iron Alloy, composed of tungsten, nickel, and iron, provides high strength, high toughness, excellent impact resistance, and corrosion resistance, making it ideal for nuclear reactor components, nuclear waste storage containers, and industrial flaw detection equipment; the Tungsten-Nickel-Copper Alloy, made from tungsten, nickel, and copper, features non-magnetic properties, good thermal conductivity, oxidation resistance, and excellent processability, suitable for MRI equipment, aerospace radiation protection, and precision instrument shielding; and the Tungsten-Based Polymer, a composite of tungsten powder with resin rubber, offers high flexibility, lightweight design, environmental friendliness, and ease of manual molding, catering to flexible protective clothing, portable medical devices, and temporary shielding facilities.

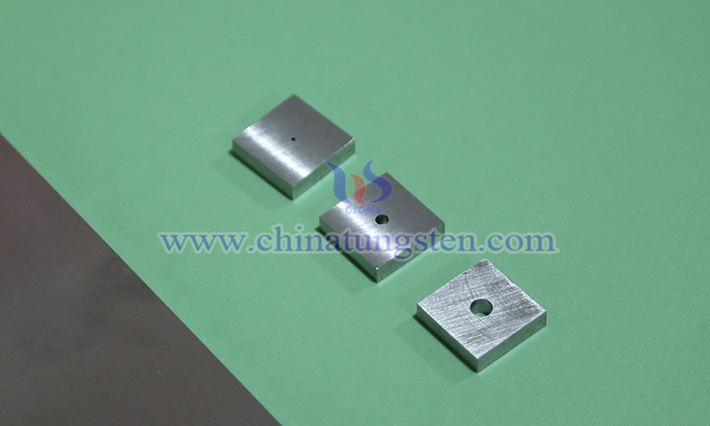

Tungsten alloy shielding components are designed in various shapes to meet perse radiation protection needs, including plate-shaped components used for medical radiation protection plates and nuclear industry shielding plates; cylindrical components applied as nuclear medicine syringe shielding sleeves; ring-shaped components utilized in gamma knife collimator rings and nuclear reactor shielding rings; box/can-shaped components serving as radioactive waste storage boxes, medical shielding boxes, and radioactive containers; spherical components employed in nuclear fuel transport spherical shells and radiation source shielding balls; conical components designed for X-ray protection cones and gamma ray focusing cones; rod-shaped components integrated into nuclear reactor control rod shielding; tubular components applied in nuclear medicine radiation pipe shielding and medical X-ray tubes; and mesh-shaped components used for radioactive lab protection nets and nuclear facility ventilation shielding.

III. Application Fields of Tungsten Alloy Shielding Components

Medical Radiation Protection

In the medical field, tungsten alloy shielding components are core elements in nuclear medicine and radiotherapy. In CT and X-ray equipment, tungsten alloy collimators control radiation beams, focusing on tumor areas while minimizing damage to healthy tissues. The high density of tungsten alloys allows for thin designs, reducing equipment weight and facilitating mobile imaging systems. Compared to lead, tungsten alloys are non-toxic, reducing secondary pollution risks. In PET scanners, tungsten alloy shielding containers protect radioactive isotope syringes, effectively lowering radiation risks and ensuring the safety of medical staff. In nuclear magnetic resonance (NMR) devices, non-magnetic tungsten-nickel-copper alloys prevent magnetic field interference, maintaining imaging accuracy. Tungsten alloy multi-leaf collimators in tumor radiotherapy enable dynamic beam adjustments, enhancing treatment outcomes.

Nuclear Industry

The nuclear industry demands high-temperature resistance and strength from shielding materials, where tungsten alloy shielding components excel. In nuclear reactors, tungsten alloys are used for control rod sleeves and radiation shielding walls to absorb neutron flux and prevent leaks. Their excellent corrosion resistance withstands coolant environment erosion, extending component lifespan. In nuclear waste storage containers, tungsten alloy covers provide multi-layer protection, isolating radioactive rays for safe transportation. In the nuclear fuel cycle, tungsten alloy shielding components protect monitoring equipment sensors from radiation damage. In renewable energy applications like wind power radiation detection, tungsten alloy components optimize space layout and improve efficiency.

Industrial Inspection

Industrial non-destructive testing relies on tungsten alloy shielding components for efficient radiation imaging. In petroleum pipeline and aviation component inspection scenarios, tungsten alloy collimators focus gamma ray sources, providing reliable support for clear imaging while shielding scattered radiation to reduce operational risks. The processing flexibility of tungsten alloys supports custom shapes for complex workpieces. In weld quality testing, tungsten alloy shielding covers protect flaw detectors, ensuring equipment stability. In food and pharmaceutical industries, tungsten alloys are used in radiation sterilization equipment shielding layers, meeting hygiene standards and preventing contamination.

Geological Exploration

Tungsten alloy shielding components, with their high density and excellent radiation attenuation, are widely used in geological exploration. During well logging, gamma ray sources penetrate rock layers, and instruments analyze data to identify oil, gas, or minerals. Tungsten alloy collimators guide radiation beams, improving accuracy; shielding sleeves absorb scattered radiation, ensuring personnel safety. In drilling detection, tungsten alloy plate or tubular shielding supports X-ray equipment to scan rock cores, identifying fractures and mineral distribution.

Aerospace

The aerospace sector requires high space utilization, where tungsten alloy shielding components leverage their high density for compact designs. In satellite radiation protection, tungsten alloy plates block cosmic rays, safeguarding electronic components. In spacecraft re-entry modules, tungsten alloys shield against thermal radiation, enduring extreme atmospheric re-entry conditions.

Military Defense

Tungsten alloys, with their high density, excellent radiation shielding, and mechanical stability, are the preferred materials for nuclear radiation protection in military defense. In nuclear-powered equipment, tungsten alloy shielding plates and cans effectively absorb gamma rays and neutron radiation, preventing leaks. In military detection equipment, tungsten alloy shielding components are used in X-ray imaging and gamma ray detectors, limiting radiation spread and enhancing safety. In nuclear submarines, tungsten alloy shielding components adjust ballast tank centers of gravity while shielding reactor radiation, ensuring reliability during deep-sea missions.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com